Cladding

Filter by Process Zone:

Faster, More Consistent Consumables Ensure High-performance Applications

Advancements in weld quality and ease of use improve the productivity of wire feeders, filler metals and electrodes.

Airgas’ Sustainable Welding Innovations Improve Quality, Productivity and Efficiency

Airgas enables your fabrication operation to “fill your potential.”

Welding Technology: Robotics, Automation and Cobots

Moving beyond high-mix, low-volume welding work, cobots are more and more suitable for laser welding, becoming increasingly more portable, and are incorporating coordinated motion to optimize cycle times.

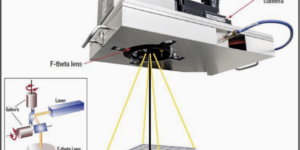

Galvo Scan Heads for Precision Laser Welding Manufacturing

Quick and accurate point-to-point positioning can shave seconds off cycle times.

Five Equipment Adjustments to Improve Weld Quality

Regardless of your skill level, using subpar equipment will put your work at risk or make it harder to optimize output.

Cutting-edge Welding Solutions to be Showcased at FABTECH 2023

Miller Electric Mfg. brings the “Power of Blue” to the show floor, where attendees can try out the newest technologies live and discover products to help evaluate your operations.

Five Tips for Implementing a Robotic Welding Cell

Get the most from your robotic welding investment through careful planning and continued monitoring.

Best Practices for Cutting Wheel Safety With a Variety of Wheel Diameters

Cutting wheels are an important component in metal fabrication. Place an emphasis on following best practices regarding the various diameters of cutting wheels.

Smart Finishes: Surface Preparation and Finishing

Thanks to advancements, the steps involved in surface prep and finishing processes are fewer, and products are more versatile and safer.

Achieve Consistent Welding Output, Repeatable Processes and Precision Welds

Achieve Consistent Welding Output, Repeatable Processes and Precision Welds

Compact Cladding Cell Accommodates Diameters Up To 3.25 Feet

Fronius has taken a simple, compact solution for cladding applications on smaller parts and developed it for larger tasks. The all-in-one cell’s controls support two processes: TIG hot wire and a two-wire SpeedClad Twin process that’s three times faster.

Laser Cladding Services

For repairing damaged components and enhancing surface protection properties for better wear or corrosion resistance, laser cladding services from Alabama Laser use lasers to deposit a layer of material onto a substrate utilizing either powder or wire.