Chucks

Filter by Process Zone:

Turnkey, Custom Engineered Workholding Services for Prismatic & Turning Machining

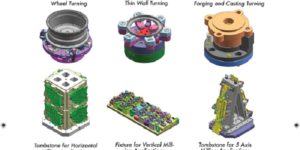

Kitagawa North-Tech provides turnkey systems for machine shops that face productivity challenges or specific machining problems in their vertical, horizontal, multi-axis prismatic milling and turning, forging and casting operations.

One Closer, Four Work Holding Systems

Flex Grip closers from Lexair can boost productivity in 4-axis, 5-axis, rotary indexer and stationary machining operations by reducing set up times with 10 second collet change capability and .0002 in part accuracy.

Kitagawa North-Tech Hires Regional Sales Manager

Edward Borsos now sells and supports standard chucks, advanced chucks and engineered rotational and prismatic workholding systems.

Röhm Group Acquired by Rothenberger

This deal further strengthens Röhm operations and positions them for continued robust growth.

Kitagawa-Northtech Moves Web Domain and Location

This new site is a refresh of their brand and product content for their customers in North America.

Röhm Appoints New Regional Sales Managers

Mark Thompson, Josh Vanderveer, and Jonathan Napier have joined their sales team.

How to Provide Uniform Pressure on Jaws for Consistent Bore in Oil and Gas Jobs

Jaw forming rings from Dillon are mounted in direct contact with the top jaw so that the jaw forming ring preloads the chucking system and grips the workpiece more firmly to maximize jaw life for cutting and forming operations, providing uniform pressure on all jaws for a consistent bore.

Whittemore Expands Sales Territory

They now serve Kansas and Missouri with tools for metal cutting, broaching, gauging, workholding, part marking and managing swarf.

Röhm Invests in Repair and Rebuild Services

Their comprehensive chuck repair and rebuild services provide a quick turnkey approach for shops to install, maintain and repair their workholding devices.

Slimmed-Down Milling Chuck for Precise, Powerful Cutting

Perfect for clamping in confined areas, Super Slim Hydraulic Chucks from BIG KAISER directly clamp ultra-small drills, reamers, ball mills, end mills, diamond reamers and grinding tools with shank diameters of 3 mm or 4 mm, all without needing a reduction sleeve.

Modernizing the Standard for Balancing Tools and Tool Systems

Did you realize that the G2.5 balance specification in ISO 1940-1 is no longer practical, technically possible or economically feasible in today’s advanced manufacturing environment? Here’s the good news: A new standard is now being developed that applies to all of today’s relevant variables for safe and productive machining. Say hello to ISO 16084.

Kitagawa North-Tech Adds Sales Manager

Shawn Luschei has rejoined them as a senior manager of sales for North America.