Chucks

Filter by Process Zone:

As Machine Technology Advances, The Chuck Must Follow

Just as the right workholding can improve your bottom line, inappropriate workholding can eat into profits. Make sure the chuck that came with your lathe isn’t keeping the machine from delivering the throughput and increased capacity it’s capable of.

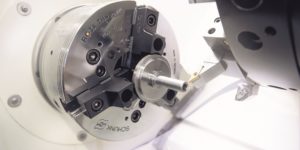

Power Chuck Saves Spindle Wear and Tear

SMW Autoblok’s HFKs-2g high-precision power chuck delivers twice the grip force than standard 3-jaw chucks. Use it for high volume lathe and mill turn center applications including heavy-duty precision machining of easily deformed workpieces.

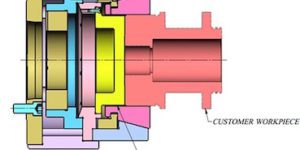

Versatile Collet Chuck System Outperforms Conventional Jaw Chucks

Speedgrip Chuck Company’s standard external collet chuck system combines the benefits of high-precision workholding with in-stock availability to increase precision and productivity.

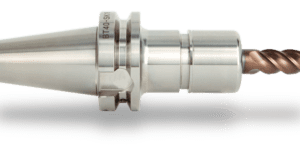

Collet Chucks Provide Flexibility Without Compromising Runout Accuracy

Available in a wide variety of toolholder lengths and diameters for optimal rigidity and clearance, Samchully Workholding’s SK series provide 1 micron runout accuracy as well as three times better runout repeatability and double the gripping force of a comparable ER collet chuck.

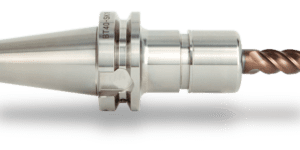

BVC Interface, Additional Inch Sizes for Hydraulic Chuck Line

Big Kaiser’s HDC jet-through hydraulic chuck line is designed for high-precision 5-axis machining. It’ll fit practically any application in the automotive, aerospace, medical, and die and mold industries.

Collet Chucks Provide Flexibility Without Compromising Runout Accuracy

Available in a wide variety of toolholder lengths and diameters for optimal rigidity and clearance, Samchully Workholding’s SK series provide 1 micron runout accuracy as well as three times better runout repeatability and double the gripping force of a comparable ER collet chuck.

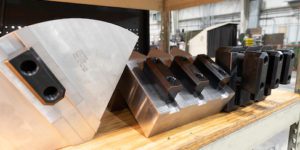

Quick-Change Nuts Cut Jaw Change Time By At Least 50%

Ideal for workholding applications that require durability and high strength, such as high-speed machining, Dillon’s Fast-Trac jaw nuts provide more productivity per square foot of manufacturing space. They convert standard chucks 6 inches to 24 inches in diameter into quick-change chucks.

Digital 3-D Sensor for Milling and Eroding Machines

Tramming in a workpiece or fixture to a machine, measuring lengths and depths, checking flatness, or aligning workpieces and vise? Haimer USA’s 3-D sensors make locating the edge in XYZ as easy as 1-2-3.

Kitagawa Northtech, Inc., Acquires Tecnara Tooling Systems’ Core Products

Kitagawa NC Rotary Tables and exclusive distribution rights to MST Yellow Angle Head products are included in the deal that took effect April 1. The two companies have enjoyed a successful sales and business relationships for over 25 years.

Microspindle Converter Operates Two Spindles Simultaneously

IBAG North America’s space-saving converter enables two microline spindles to operate simultaneously from one drive at speeds from 5,000 rpm up to 100,000 rpm.

Reamer’s Feed Rates Are 70% Faster Than Traditional Reamers

With no setting required, even a novice can quickly install Monaghan Tooling Group’s Top Speed Ring (TSR) reamer. Four additional cutting heads ensure longer service life, saving time and money.

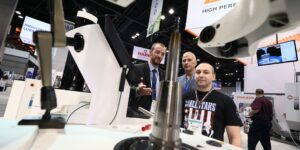

Same Show, New Booth – IMTS Update from Haimer USA

Six thousand-square-foot ‘real estate’ will be a dynamic, interactive attendee destination.