Chucks

Filter by Process Zone:

Chucks

Chucks comprise a category of universal holding devices used in turning applications, capable of interior diameter or outer diameter (ID or OD) clamping. Chucks feature two to eight jaws, catered to fit the shape of the workpiece. Lathe chucks can…

Jaw Modules Begin New Era in Workholding

In this new multitasking modular system from Hainbuch, the chuck and jaw module do not just result in a jaw chuck, they become a quick change clamping solution for many applications that can be quickly changed to cover a large clamping range.

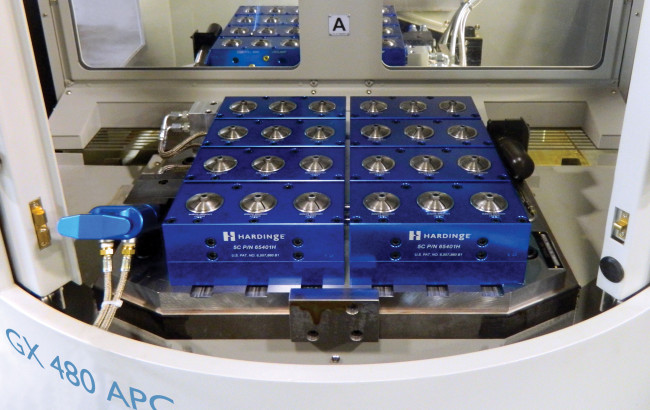

Base Plates Expand Flexible 5-Axis Workholding

The 5-Axis Duo Bridge with Dual 45 deg 105/65 base plates from BIG Kaiser mount directly on the top of a 5-axis table or load through a pair of zero-point chucks to integrate flexibility and functionality for 5-axis applications or 5-sided machining via multiple part transfers.

To Have Is To Hold

An examination of some of the latest chucks, jaws, collets and other tool and workholding technologies that can help you reduce setup time, increase spindle utilization and improve your competitive edge.

Power Chuck Is Ideal for Clamping Brake Drums, Bearings, Disks

This hermetically sealed, maintenance free 3 or 6 jaw power chuck from SCHUNK provides high precision on noncircular components by using an active pull down to achieve theparalleism and perpendicularity.

Haimer USA, LLC

An overview of the company and its organization, products, services and capabilities.

Hard Turning on a Magnetic Chuck

Green or hard turning on a magnet is becoming more accepted as an alternative for lathe chucking, particularly for rings which are vulnerable to deflection.

Deformation-Free Clamping: From the Plastic Chuck Jaw to the Hybrid Chuck

When highly deformable workpieces need processing, conventional 3-jaw chucks quickly reach their limits. This primer from Schunk identifies different clamping tools and devices for deformation-free workpiece clamping and the criteria they should meet to demand efficiency and precision.

Grip Force Repeatability in Lathes

Kyle Zellman of SMW-Autoblok examines how clamp force repeatability affects process capability, deformation problems, released part safety and damage, and can be a solution to reducing your downtime and maintenance costs.

Shorter Setup Times with Quick Jaw Change Chuck

With the ROTA THWplus chuck from Schunk a complete jaw set can be changed in less than 60 seconds with a repeatability of less than 0.0005 in, which eliminates the need to re-bore jaws.

PIN VISE TOOL HOLDERS FOR MINIATURE BRUSHES

Pin vises from Brush Research Manufacturing reduce operator fatigue and improve efficiency by securely holding small diameter miniature deburring brushes when stem diameters are too small for chucking in automated machines.

Chuck for Clamping Large Thin-Walled Parts

The ROTA NCR precision 6-jaw compensation chuck from Schunk is ideal for clamping thin-walled components and for virtually any turning application on large lathes.