Chucks

Filter by Process Zone:

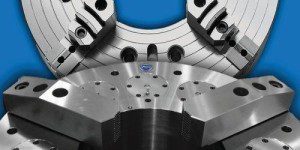

Full Grip Jaws Minimize Distortion for Thin-Walled Parts

Aluminum full grip jaws from Dillon are ideal for machining thin-walled valves, cylinders, specialty wheels and gears, housings and enclosures, adaptors and connectors, aluminum and steel shells, flanges, retainer rings, smog control air pump rotors, gas turbine parts, thin-wall tubing, cylinder liners for diesel engines and more.

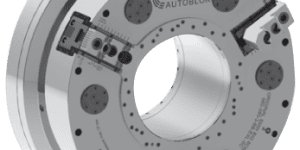

Powerful, Versatile Solutions for Demanding Applications

The Unilock ESM 138 Turbo and ERGO 138 chucks from BIG KAISER provide quick and easy setup and loading, self-guided top-side mounting and zero-point clamping.

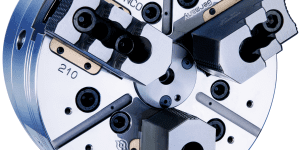

Power Chuck Packages

Each chuck system from TMX Workholding Solutions is customized with high tensile drawtubes to maximize the through bore capacity for each machine tool.

Quick Change Collet Chuck

The Low-Profile 65 mm Dead-Length FlexC Quick Change Collet Chuck from Hardinge can be customized to fit any spindle for better tool clearances compared to similar alternatives.

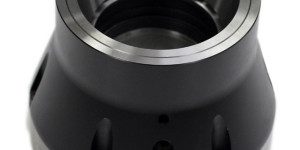

Front-End Spring Clamp Power Chuck

The BIG BORE BB-EXL-SC2G air chuck from SMW Autoblok is a front-end spring clamp power chuck provides an extra-long jaw stroke and increased safety monitoring that is ideal for oil and gas applications.

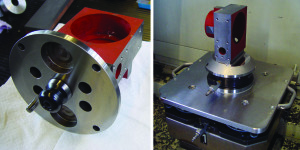

Upgrade Easily to Smaller Lot Sizes

These quick change chucks and clamping systems from SCHUNK make full use of the flexibility that machine tools now offer so that the same part cost can be achieved in much smaller production runs.

Beat the Competition on a Budget with this Entry-Level ‘Automation’

The way we machine parts has changed significantly over the years. Now it’s time to change how we think about workholding too.

Advanced Hydraulic Chucks Improve Machined Part Quality

ERI America introduces high performance Precision Hydraulic Chucks from WTE Mapal that offer extreme temperature stability, super strong holding forces combined with excellent vibration damping, and high radial stiffness.

How Shrink Fit Chucks Fit Single Blade Applications

See why Starrag uses shrink fit chucks so their rotationally symmetric clamping body has less interfering contours and higher run-out accuracy when roughing and finishing hard-to-cut materials used for highly precise turbine blades, impellers, blisks and other structurally complex parts.

Röhm Holds Grand Opening Oktoberfest

Their new 32,000 sq ft facility in Suwanee, GA, is three times larger than their previous location in order to manufacture in the U.S. and expand service and support operations across North America.

Put On Hold

The increase in higher precision machining is creating demand for stronger, more durable, faster acting, closer tolerance chucks and collets that can grip and hold the parts and the tools being used. Here is a review of some of the latest chuck and collet solutions that meet that demand.

Clamping for Difficult Machining Applications

These clamping systems from Lexair are ideal upgrades for manual lathes, rotary tables and indexers that require higher grip force for difficult applications.