Chucks

Filter by Process Zone:

Jaw Nuts and Keys Handle High Stresses, Mechanical Forces in Heavy Machining

Ideal for high speed machining, Dillon Jaw Nuts and Keys provide superior wear resistance, impact resistance, higher tensile strength, and extended jaw nut life.

Sealed Quick Jaw Change Chucks

Ideal for mass production operations, KNCS-2G next generation of quick jaw change chucks from SMW Autoblok provide extra defense against chips, lubricant and other debris, and only require lubrication every third shift.

IMTS 2016 Sneak Peek: Tooling & Workholding

Here is a sneak peek at some of the state-of-the-art tooling and workholding systems that will be exhibited on the show floor at McCormick Place in Chicago from September 12-17.

Innovative Workholding that Maximizes Machine Time

The DURO-TA XT key bar chuck from Röhm offers reduced weight, workpiece accessibility and application flexibility to maximize milling and turning machine potential.

High Precision Milling / Drilling Chucks

As the only chuck with a 1:16 worm gear, the FPC Chuck from Emuge delivers three tons of traction force, provides 100 percent holding power for maximum rigidity, and absorbs virtually all vibration for maximum dampening.

Röhm Expands Regional Sales Team

Al Dopf, Edward Borsos, Jennifer Allison, Jimmy Clark and Rodney Payton now handle sales and service in various regions across North America.

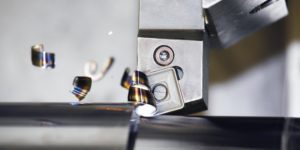

Stick to the Story

Check out how a special dual contact stick turning toolholder developed by Briney Tool Systems eliminated the need for one shop to re-engineer their catalog of lathe stick tools.

Reduce Change-Overs to Ten Seconds

Quick-Grip CNC Collet Chucks from Royal Products enable shops to improve their production times and accuracy while eliminating change-over problems associated with standard collets.

Röhm Expands Service in Mexico with New Office in Monterrey

The facility supports increasing opportunities in clamping and gripping technology in Mexico and Central America.

Innovations in Workholding

Workholding must be updated to make full use of the small lot flexibility that machine tools now offer so that the same part cost can be achieved in much shorter production runs. Here are some of the latest advances in workholding technology for shops to consider.

The Freedom of Magnetic Workholding

MagVISE workholding chucks from Techniks are used for face milling, edge milling, drilling, and even boring operations on all four sides and the top of thick or thin workpieces.

Synthetic Gripper for Complex, Sensitive Workpieces

The RRMG Synthetic Gripper 3 from Röhm uses free-form surfaces that adapt to different workpieces geometries, whether they be round or prismatic in shape.