Chucks

Filter by Process Zone:

Innovative Chucks for Oil/Gas Components

Röhm features HSFZ swivel chucks that permit machining of bushings, connectors and adaptors from both sides and LVE-V-AZ pneumatic 6-jaw front-end chucks that enable precise, centered and productive turning of large, long pipe ends.

Heavy Duty Shrink Fit Chucks

The Heavy Duty Shrink Fit Chuck from Haimer shrinks both carbide and HSS tools and accommodates round shank tools up to 2.0 in diameter in a variety of tapers.

Kitagawa-NorthTech Names New VP

Kevin Bennett now leads their sales and marketing operations in North America.

Kitagawa-NorthTech Hires Manager of Engineering

Ed Johannesen now leads their design engineering, quality and continuous improvement operations.

Medical Machining: Tooling

Take a closer look at some of the newest tooling that can help contract manufacturers meet the machining, micro machining, and laser processing demands for smaller and more complex surgical implants, orthotic devices and medical instruments that are being made from newer materials – and still hold their costs down.

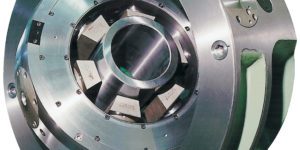

Precision Hydraulic Chucks for Medical Manufacturing

High performance WTE Precision Hydraulic Chucks from ERI America provide extreme temperature stability, super strong holding forces combined with excellent vibration damping and high radial stiffness to guarantee improved surface qualities on the workpiece during machining.

The World’s Smallest and Strongest Clamping System

The extremely thin VERO-S NSE mini pneumatic quick-change module from SCHUNK is ideal for retrofitting and fully utilizing existing machines to directly clamp and process small precision parts used in medical technology.

IMTS 2016: Tooling & Workholding Systems

Good tooling not only gives new capability to older equipment, it is a key to productivity and cost efficiency on all machine tools. Maximize the investment in your machinery and equipment with the latest tooling technology and state-of-the-art workholding systems that allow minimum setup and machining time.

Complete Machining of Crankshafts in Just One Setup

Automation meets clamping technology in the combination of a shaft chuck, steady rest and gripping technology from Röhm that is ideal for machining and transport of crankshafts in different manufacturing stages.

High Speed Spindles for Milling, Cutting and Grinding

Powerful high speed Micro Line spindles from IBAG fit Swiss turning machines in spindle sizes from 16 mm to 33 mm diameter, speeds to 120,000 rpm and power to 390 watts.

Do Lathe Operations on the Bed of Your Mill

RapidTurn from Tormach securely positions parts in 15 deg increments for secondary work on the primary spindle of the mill, which is ideal for cutting wrench flats or drilling cross holes on turned parts without additional setups.

Bilz Tool Adds New Manufacturer’s Reps

Denco is now their agency for the southeastern U.S. and Tool Application Services covers Southern California and northwest Mexico.