Automation/Robotics

Filter by Process Zone:

Quick-Change Robotic Arm Gripper

The RV36 Gripper from Kurt Workholding saves space and money while improving efficiency with quick-change, customizable jaws and custom accessories. Its double-acting piston allows for maximum clamping and un-clamping force.

The Six Things COVID-19’s Manufacturing Winners Have in Common

AMT – The Association For Manufacturing Technology President Doug Woods outlines the six transformative technologies that are helping companies meet swiftly changing market demand without sacrificing quality or employee safety.

Robotic Revolution: The Dawn of True Human/Machine Collaboration

The pandemic prompted manufacturers to fast-track automation plans to safely produce and deliver competitively priced products. Association for Advancing Automation (A3) President Jeff Burnstein explains the potential impact of cobots.

High-Speed Robots for Small-Part Processing

Available in two compact models, Yaskawa Motoman’s horizontally articulated SG-Series SCARA robots are highly repeatable and offer a wide variety of fieldbus connectivity options. They easily integrate with existing robotic automation and are easily redeployed.

A Hydraulic Press Solution for Virtually Any Need

Greenerd Press & Machine provides customized hydraulic presses that are flexible, productive, and reliable. As a Fanuc America system integrator, the company also configures turnkey robotic product-handling solutions.

Harsh Environments Don’t Faze This Robot and Controller

ABB offers the IRB 1100 robot and OmniCore controller in IP67- and IP54-rated versions featuring extra protection against water and dust. Applications include 3C polishing, wet grinding, buffing, and deburring.

Think of Weld Traceability As Your Company’s Unofficial Insurance Policy

Robotic welding cells with arc-monitoring and -reporting capability provide peace of mind in two ways. They ensure consistent production and automatically collect and store data a fabrication company can easily share with customers that impose traceability requirements.

Paint It Pretty With Precise and Versatile 6-Axis Robots

Armed with application-specific software and a controller that coordinates operation of the robot and painting devices, the three machines that comprise Yaskawa Motoman’s MPX Series precisely dispense paint on components of virtually any size.

World’s First Robot With Process-Optimized Motion Modes

In addition to providing the longest reach in the high-payload category and featuring a slimmer profile, KUKA’s updated KR Quantec robot offers three software plug-ins to maximize performance, path, and cycle times.

Plug-and-Play Intelligent Screwdriver Drives ROI

OnRobot’s Screwdriver can be deployed and redeployed for different applications in minutes. Its built-in smart features – including precise torque and embedded axis control – simplify programming and drive productivity.

Will the Real Collaborative Robot (aka Cobot) Please Stand Up?

A robotic system is ‘collaborative’ only if all elements – robot, tooling, workpiece, and work area – meet international safety standards. Depending on application, you may be able to turn a standard industrial robot into a cobot and comply.

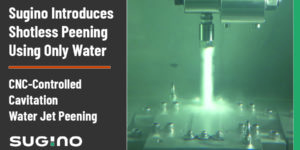

Peen and Wash Simultaneously With Shotless Process That Uses Only Water

Sugino Machine adds waterjet peening with up to 5-axis CNC control to its lineup of equipment that uses water to atomize, deburr, and clean. Peen inside holes, tubes, and cavities without masking or the waste and mess of standard shot peening.