Automation/Robotics

Filter by Process Zone:

Balancing Technologies Contribute Significantly to Reliable Machining Operations

By ensuring perfect balance, balancing technologies reduce the risk of damage and improve the overall efficiency of the manufacturing process.

Why Tool Balancing can Benefit Every Machining Operation

Balancing tool assemblies set the stage for smooth machining that produces parts with consistent surface finish. Balancing also accelerates production because speeds and feeds can increase without compromising the part.

AI’s Impact on Metalworking: Empowering Frontline Workers with Intuitive Software

By simplifying software and making it more intuitive, AI will empower frontline workers to be more productive, efficient and engaged.

Significant Advancements of Field-proven Phased Array Inspection Solutions

Efficiency-optimizing enhancements unveiled by Evident Corp. on its MapROVER™ and SteerROVER™ corrosion and weld inspection scanners.

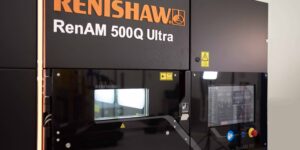

New Scanning Technology Achieves up to 50% Reduction in Additive Manufacturing Build Times

Renishaw’s patented TEMPUS technology enhances the class-leading productivity of the RenAM500 series metal additive manufacturing systems with reduced build times, detailed build insights and advanced process monitoring.

New Solution Brings Hybrid AI, 3D Imaging, and Intelligent Robotic Planning to Any Robotic-based Visual Inspection

Kitov.ai’s K-BOX machine vision systems solve manufacturing’s most demanding inspections.

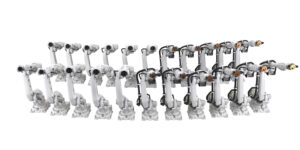

Company Expands Large Robot Family with Four Energy Saving Models, 22 Variants

ABB Robotics‘ next generation models include the IRB 6710, IRB 6720, IRB 6730 and IRB 6740, suitable for payloads ranging from 150 kg to 310 kg, with a reach from 2.5 m to 3.2 m.

Made to Measure

Modern 3D metrology is becoming the eyes and ears of the production floor, bringing multiple advantages to the manufacturing world.

Robotic Thread Verification Enhances Q-Span® Automated Gauging System

Thread gauging is the latest in a range of manual gauging processes that QC teams can automate with the flexible, DIY robotic workstation.

New Application Offers Fully Automated Tool Calibration for Industrial Robots

RoboDK’s TwinTool improves a tool’s accuracy in a wide variety of manufacturing applications.

Portable Cobot Inspection System Introduced at Control Show in Germany

The portable cobot-based 3D scanning and measurement solution is a partnership of IBS Quality GmbH and Verisurf Software, Inc.

High Speed, Accurate and Easy to Use Measurement and Inspection Tools

Thanks to the latest innovations in M&I, your shop can easily conduct high levels of quality assurance.