Automation/Robotics

Filter by Process Zone:

Robotic Welding Automation for the Small Job Shop

The conclusion of our three-part series on automation for the small shop examines the primary components involved in the justification and payback of your capital expenditure so that you can optimize your financial return on investment.

Greg Scheu Appointed Executive Committee Member

Group EC member to focus on realizing value from acquisitions and driving profitable growth in the expanded North America business

Automation for the Small Job Shop: Competitive Advantage

In part two of this three-part series, we walk through the mechanics of process control on the floor, the flexibility and lean manufacturing capabilities of automated welding, and how robots handle all sorts, sizes, shapes of parts – ideal solutions for the competitive job shop.

Evana Automation Supplies Custom Screw Driving System to Prominent Products Manufacturer

Evana’s automated solution will reduce manual labor and increase quality assurance for aluminum fencing assembly process.

First SVIA PickVision Machine Tending System Installed in the US

ABB Robotics system at Atlas Copco to tend three Okuma lathes that manufacture parts used in mining applications.

ESAB Sponsors University of Toronto Baja Team in SAE Design Competition

ESAB will support the University of Toronto Baja Team with the donation of welding equipment, consumables and personal protection accessories as they compete to design and build a rugged off-road vehicle.

FILL THE GAP: ROBOTS FOCUS ON QUALITY

Though many might argue that the progression of robotic welding technology has always focused on profit, Heath Suraba of Lincoln Electric explains why you must have quality before you can realize profit.

MOTOMAN INTERFACE FOR LINCOLN ELECTRIC POWER WAVE POWER SOURCES

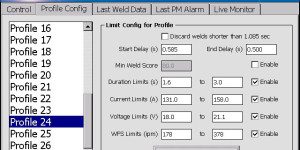

Users can now program weld parameters as work point/trim or amps/volts, along with up to four “Wave Controls” with allowable limits displayed from the process library in the Lincoln power source. Users can also program Lincoln’s Production Monitoring™ process limits and define alarm and fault conditions from the robot’s touch screen pendant display.

New Robotic Welding Cell Dramatically Increases Robotic Welding Envelope

In order to meet the goal of a sizable increase in their robotic welding envelop, D&S Manufacturing has integrated a new cell system from Wolf Robotics featuring two ABB IRB 2600 six-axis robots, two Lincoln Welding power supplies and an IRBP K servo positioner, all controlled by a single ABB IRC5 MultiMove control.

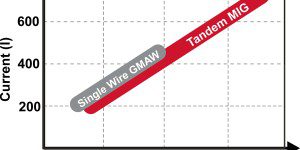

Synchronized Tandem MIG® Process Revealed

This examination of Tandem MIG shows how it extends the welding productivity range beyond that possible with conventional single-wire processes.

Miller Electric Donates Over $1 Million in Robotic Welding Equipment to Technology Program

In addition to the donation, Miller worked closely with the university’s staff to offer training to instructors on the new equipment.

Automation for the Small Job Shop: Why and What to Do with It

In part one of this three-part series, we examine how the simplicity, easy training and quick startup of new plug-and-play robotic cells – some for as little as $35,000 – can help even the smallest shops overcome labor shortages and become more competitive.