Automation/Robotics

Filter by Process Zone:

Eight Ways to Improve Welding Productivity Using a Weld Camera

An automated welding environment can be too congested or dangerous for operators to directly monitor the welding tip while under operation. How can they properly monitor the welding process remotely?

Purging and Monitoring Systems for Welding Pipework in Power Stations

COB Industries offers the HFT HotPurge system with glass treated silicone cloth that resist temperatures up to 1,400 deg F, and the lightweight, portable HFT PurgEye 300 Plus gas analyzer that measures oxygen levels down to 1 ppm.

Welding Equipment for Pipe and Tube Fabrication on the Jobsite

The Dynasty 280 DX with CV from Miller Electric includes Auto-Line technology and can TIG weld 0.012 in to 3/8 in aluminum and 0.004 in to 3/8 in steel with superior arc performance. It can TIG weld with AC waveforms, including advanced squarewave, soft squarewave, sine wave and triangular wave.

How a Welding System Conversion Increased Production at Exterran by 30 Percent

Take a closer look at how a welding process conversion and equipment standardization in their Brittmoore pipe shop in Houston helped to significantly increase productivity and improve on already-high weld passage rates in only a few months.

Laser Welding Lines for Powertrain Components

Based on their standard laser welding modules, Coldwater Machine Company customizes each system to suit specific application requirements.

Robots and Automation Shatter Records in North America

Robotics, machine vision, and motion control applications gave reached their highest levels of growth ever.

Laser Welding that Forgives Imperfections

FusionLine technology in the new TruLaser Weld 5000 laser welding cell from TRUMPF overcomes part imperfections when welding by closing gaps up to 0.04 in wide, with welding seam results and process times that significantly outperform conventional welding techniques.

Fully Automatic Multi-Gun Resistance Welder

This multi-gun resistance welding cell from Taylor-Winfield joins and assembles multiple components in one operation and can complete 20 different spot welds within five seconds, with minimum operator interaction.

LaserNett Moves to New Location

Their new 87,000 sq ft facility includes enough land for a 60,000 sq ft expansion in the future.

FANUC Marks Production of 500,000th Robot

They reach a key milestone in keeping pace with the growing demand for automation in the metalworking industry.

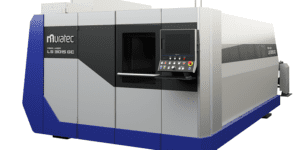

Economical Fiber Laser Cutting of Ferrous and Non-Ferrous Materials

The compact LS3015GC fiber laser cutting system from Murata Machinery uses an integrated flying optics system with internal controls that monitor laser output, laser beam and light reflection for superior cutting of ferrous and non-ferrous materials, including steel, stainless steel, aluminum, brass and bronze.

New Lincoln Electric Welding Technology & Training Center to Open in January 2018

This 100,000+ sq ft building doubles their welding education capacity and will be one of the most advanced facilities of its kind.