Automation/Robotics

Filter by Process Zone:

Advanced Robots, Turnkey Workcells, Collaborative Technology and More to Increase Productivity

The heavy duty, large reach MH900 Robot; the light 6-axis MotoMini for tabletop, floor, ceiling or wall-mount installations; and the Motoman AR1440 arc welding robot are some of the latest automation systems from Yaskawa Motoman that improve productivity in a wide variety of manufacturing operations.

Connected Digital Ecosystems for Automated Welding and Plasma Cutting

WeldCloud and CutCloud platforms from ESAB connect on-premise hybrid and cloud-based digital ecosystems for automated welding and mechanized cutting with online data management that drives continuous improvement in operations.

Self-Integrating a Robotic Welding System

To stay competitive, many shops must choose between building a robotic workcell or buying a turnkey system. DIY robotic integration is possible, but certain critical factors should be considered because the end user assumes greater responsibility and acquires more project risk. There is much to know and manage, from process welding requirements and robotic cell design to tooling requirements and system documentation.

Co-Founder of Universal Robots Wins Award

Esben Østergaard is honored with the prestigious Engelberger Robotics Award.

Xiris Opens European Office

Their office in Ratingen, Germany, offers annual recertification services of weld inspection systems used in the tube industry.

Robotic Guidelines for the Production of Safety Critical Welds

Security features, tracking, arc monitoring and traceability make it nearly impossible to stray from established protocols and parameters that maintain weld integrity during the robotic welding of safety critical welds. It may take a considerable amount of upfront work to get to full data harmonization, but the results are confident customers and improved product quality that can help secure future operations.

ATTC Hires Robotic Automation Specialist

Zac Marnell now provides specialized sales and service in robotic and automated welding tools and applications.

Don’t Spec a Welding System Until You’ve Done This

While increasing throughput, improving product quality, dealing with labor shortage and right-sizing a robotic cell are valid factors to consider when pricing out a system, the best designed system can still miss the mark. You should really pay more attention to these two factors before diving too deep into cell design and component specifications.

JR Automation Acquires Setpoint Companies

This deal expands their footprint in intelligent automated manufacturing and distribution technology systems.

Pemamek Partners with HGG

They intend to streamline and integrate precision cutting processes with high quality welding operations to dramatically benefit customers of both companies.

World’s First Collaborative Spool Welding Robot

Novarc’s Spool Welding Robot is a semi-automated robotic system for pipe welding, small pressure vessel manufacturing and other 1G welding applications.

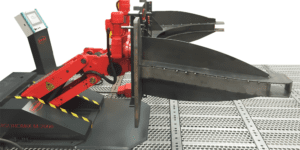

How to Maneuver Your Part Without an Overhead Crane or Brute Force

Gone are the days of using an overhead crane or brute force to maneuver parts around. The heavy duty Powered Manipulator from Bluco is a specialized modular fixturing system that raises, lowers, rotates or tilts your workpiece into any position to a comfortable working height.