Automation/Robotics

Filter by Process Zone:

How to Prevent Five Common Failures in Robotic Welding Systems

Are burnbacks, premature contact tip wear, loss of tool center point (TCP) or other problems costing your robotic welding operation time and money? Here are some tips that will improve productivity, reduce consumable costs and ensure consistent part quality in your robotic weld cell.

Pemamek and HGG Extends Partnership

Their strategic partnership now includes shipyard solutions.

AGT Robotics Receives Award

They earn the FANUC Sales Growth Award for 2017.

Yaskawa Motoman and RAMTEC Form Ohio Manufacturing Workforce Partnership

Their goal is to create a highly sustainable workforce that meets the needs of the manufacturing industry.

Through-Arm Cable Arc Welding Robot Rivals Quality of Skilled Human Welder

The BA006L arc welding robot from Kawasaki Robotics has a 6 kg payload, a hollow wrist for through-arm cabling that simplifies cable and hose management, and increased reach of 2,036 mm for welding large workpieces.

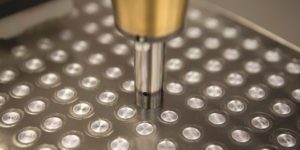

Friction Stir Spot Welding of Aluminum and Other Lightweight Materials

The SpotMeld system from Coldwater Machine can weld lightweight materials such as aluminum, magnesium, non-ferrous and dissimilar sheet material without adding additional weight to the structure, producing a weld that is near original material strength.

MIG Guns, Consumables and More for Semi-Automatic Welding and Robotic Cells

Bernard semi-automatic MIG guns and consumables and Tregaskiss robotic MIG guns, consumables and peripherals improve profitability in welding operations.

Optical Seam Tracker for Robotics and Hard Automation

The 3-line Optical Seam Tracker TH6x from Abicor Binzel uses advanced laser line technology to track the joint in real-time and guide the torch perfectly through the weld joint and create the perfect seam.

Down to the Wire

WireCrafters faced a dilemma: Manually welding their stock products had become too difficult to maintain during peak seasons. Hiring temporary welders was expensive. They needed smaller batch sizes and better inventory returns. What could they do?

How to Choose the Right Positioner for Your Robotic Welding Application

Excellence in welding automation relies heavily upon the capabilities of the positioner being used for the application. Selecting the right positioner technology requires a clear understanding of the positioner options and features that are available to gain the flexibility you need to improve weld quality and decrease cycle times.

Xiris Appoints North American Sales Director

Norm Sted will focus on creating new customer relationships and sales channels for their products.

Coldwater Machine Opens Dayton Engineering Office

This new 2,300 sq ft location houses eight engineers to support their expanding business needs.