Automation/Robotics

Filter by Process Zone:

Added Value: The Importance of Aftermarket Care

You’ve covered every detail in upfront costs and factory floorspace, but what about technical support and service after production starts? Whether buying one robot or hundreds, having access to diverse support services to ensure peak robot performance is vital to maximizing your return on investment. Here’s why.

Weld Nut Sensors Increase Process Reliability

An economical alternative to more expensive optical or vision-based systems, IP67-rated weld nut sensors from Turck reliably detect the presence or absence of a nut welded to sheet metal to ensure efficient and accurate production in welding applications.

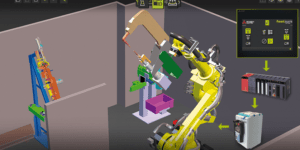

Using a 3D Virtual Environment to Reduce Downtime

Using IoT-based technology to connect robots, controllers and other real hardware to a 3D virtual environment, FASTSUITE simulation from CENIT debugs robot motion faster than ever – before downloading to actual equipment – increasing precision and efficiency to slash downtime on the shop floor

Cloud-Based Gas Detection for Hot Work Operations

With the entire iNet gas detection infrastructure from Industrial Scientific now operating through Amazon Web Services, fabrication and welding shops can quickly and easily access critical data they need online to monitor operations, prevent downtime, and save lives.

New ABB Robotics Education Affiliate

Motlow State Community College is new member of the program.

Lincoln Electric Purchases Controlling Stake of Askaynak

This deal advances their regional growth strategy in Europe, the Middle East and Africa.

Xiris Hires New Service Tech

Shivom Rathod is their new service technician for India.

Omron Microscan Names New President/CEO

Andy Zosel is appointed president and chief executive officer.

TTG Acquires Alpha Integration

This deal will help TTG expand into new markets, including the medical and cosmetics sectors.

Using Voice Input to Control Welding Systems

This voice control system developed by Fronius and their partners enables welders to use verbal commands to set amperage, arc length and other parameters without any interruption of the welding process.

What Does “Collaborative” Really Mean?

Human-robot collaboration is changing manufacturing operations by helping shops deal with competitive pressures and a lack of skilled labor, but it is not a “one size fits all” solution. Before you invest, consider the different forms of robotic collaboration and how they apply to your entire application.

AGT Robotics Wins Innovation Award

They receive the Technology Innovation of the Year Award from FANUC.