Automation/Robotics

Filter by Process Zone:

ESPRIT CAM and Alma CAM Create Robot Additive DED Programming

The partnership has resulted in a validated workflow that provides end users with dedicated additive toolpath planning and programming, as well as robot programming, simulation, verification, collision detection, and code generation. Engineers can also use the technology to achieve the above functions for subtractive finishing.

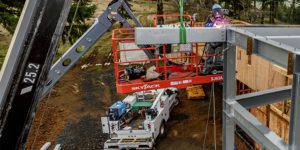

Three Ways to Cut Field Welding Costs

Walking back and forth to a vehicle to tweak an engine-driven welder/generator’s control panel takes time. Remote control devices increase productivity by putting the ability to make changes in the palm of the operator’s hand.

App Helps Avoid Welding Failures in the Field

Lincoln Electric’s NEXTime preventative maintenance app for Ranger welder/generators monitors critical functions to ensure field workers are working instead of troubleshooting productivity-sapping machine-operation issues.

Four Tools for Even Better Robotic Welding

Fronius increases seam quality without slowing cycle time with robotic assistance systems by making the wire electrode a sensor as well as filler metal. This eliminates the time and expense of maintaining sensor hardware and doesn’t restrict component accessibility.

Manage Welding Operations From Your Home Office

Multiple workers and Fronius equipment can be monitored singly and in the aggregate when networked with the company’s WeldCube Premium software. The program provides easily accessible data documentation and analysis via a central database.

The Smarter Way to Tube Weld

Robotic welding is no longer just for low-mix, high-volume production. Robot manufacturers are using artificial intelligence (AI) and machine learning to develop “smart” systems that quickly and easily handle both programming and welding.

Rugged Cobot Offers 20-Kilogram Payload for a Wide Variety of Tasks

The industry’s first IP67-rated collaborative robot, Yaskawa Motoman’s HC20XP is particularly well-suited for use in damp and splash-prone environments such as food processing. Two speeds optimize cycle time based on risk assessment and process requirements.

Flexible High-Volume, High-Performance Welding Capability

Yaskawa America’s ArcWorld 6000 pre-engineered workcells featuring Motoman AR-series arc welding robots come with virtually everything you need to get up and running quickly and safely. Available in one-, two-, or three-robot configurations.

Exposing the Dangerous Myths About Welding Equipment and Machinery

Plenty of risks accompany the operation of welding equipment and machinery – but misinformation can increase the chances for poor decision-making and hazardous mistakes. Westermans Intl. Technical Director Mark Reaney calls out some industry myths and offers tips to help you operate as safely as possible.

Robotic Welding Station Increases Strength by Ensuring Consistency

The biggest challenge to achieving a strong bond when welding thick walls are discrepancies between the CAD drawing and the in-process weld. Pemamek’s laser scan-driven control system overcomes this difficulty by automatically correcting weld path based on groove geometry.

An Introduction to Robotic Cutting, Deburring, and Finishing (CDF)

Improvements in finishing tools over the last decade have opened the door to productivity-enhancing automation. Here are solutions manufacturers can confidently implement today.

Compact Spot Welding Robot

FANUC’s R-2000iD/210FH Robot offers system uptime while operating in tight workspaces.