Additive Manufacturing Systems

Filter by Process Zone:

Laser Deposition Head Optimizes DED Processing

Optomec’s LENS LDH 3.X brings the flexibility and versatility to build, repair, coat, and clad parts into one deposition head. Variable optics system that creates three focused spot sizes optimizes directed energy deposition (DED) processing across a range of parts and applications.

3D Metal Printer Is 40% Faster Than Predecessor

The DMP Flex 350 from GF Machining Solutions is the successor to 3D Systems’ ProX DMP 320 3D metal printer. Consistent repeatability is achieved with its pure, low-oxygen environment during printing.

Sustainably Sourced Metal Powders for Additive Manufacturing

6K’s UniMelt microwave plasma platform converts recycled material into premium powder. The technology processes almost any metal type, alloy, or ceramic feedstock, which means any alloy that’s machined has the potential to become powder.

Exact Metrology Set to Open New Center in Moline

Software and hardware training for customers will be a major focus of the new location.

Subscription Pricing Introduced For Nesting Software

Hypertherm offers purchasing alternative on ProNest LT for use on smaller CNC cutting tables.

Custom Toolpaths Automate Metal Additive Repair of Titanium

AutoCLAD technology on LENS metal 3D printing systems from Optomec generates a custom toolpath for each part to automate the repair of reactive metals like titanium in a controlled argon atmosphere.

Additive Manufacturing Path Optimizer

AM Path Optimizer simulation technology from Siemens helps maximize the production yield and quality of powder bed fusion manufactured parts by solving overheating challenges and reducing scrap.

Metal AM Shifts from Prototypes to Production

By the end of 2022, production applications will account for 60 percent of market value from all produced components annually .

Optomec Reaches Milestone

They deliver their 500th industrial 3D printer.

Ingersoll Awarded Contract for Giant Telescope

The $135 million Giant Magellan Telescope structure contract will require nine years to complete.

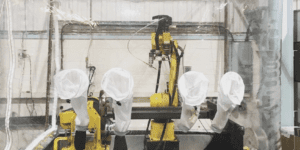

Welding Enclosures for Wire Arc Additive Manufacturing

Argweld Flexible Welding Enclosures from Huntingdon Fusion Techniques HFT keep an inert gas shield around titanium and other reactive alloy parts during wire arc additive manufacturing used in aerospace, medical and motorsport applications.

Kennametal Launches 3D Printing Business

Kennametal Additive Manufacturing uses additive solutions for faster development and production of wear-resistant parts.