Additive Manufacturing Systems

Filter by Process Zone:

3D Printing Cooperation: Photocentric and CoreTechnologie Enter into Partnership

CoreTechnologie has developed a tailored version of its 3D printing software specifically for Photocentric 3D printing machines and processes.

Desktop Metal Qualifies 4140 Low-Alloy Steel for High-Volume Additive Manufacturing of End-Use Parts

The company qualified the steel via metal binder jetting for mass production of strong steel parts that withstand high impacts, temperatures, and mechanical stresses.

GE Aviation, GE Additive Engineers Switching to Metal 3D Printing for Four Existing Parts

GE Aviation has decided to switch from investment casting to additive manufacturing for four parts based on cost and time to market.

Robot Ready for Harsh and Cleanroom Applications

The IRB 1300 industrial robot from ABB features IP67, Foundry Plus 2 and cleanroom ISO 4 versions. It performs a range of tasks that includes material handling, machine tending, polishing, assembly and testing.

New Data Definitions Added to Industry Terminology Standard

Additive manufacturing, robotics, and machine tools are among the updates to MTConnect Institute’s 1.6.0 version released last fall. One unexpected but highly relevant term – humidity – is significant to AM processes and therefore included in the new version.

New AM Alloy Swings Open 3D Options for Turbines and More

EOS NickelAlloy IN939 from German 3D metals printer company, EOS, combines high-temperature strength – at over 1500 degrees F – with crack and corrosion resistance. Its potential ranges from industrial gas turbine and microturbine parts to turbochargers, power industry parts and other extreme-conditions applications.

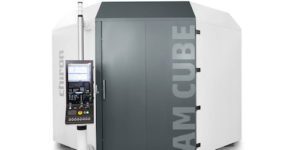

Change 3D Metal Printer’s Deposition Head While Printing, Coating

Chiron Group’s flexible additive manufacturing machine – the Chiron AM Cube – is designed with laser metal deposition technology to work efficiently in the mechanical engineering, tool manufacturing, energy production, and aerospace sectors. Its three deposition heads can perform different functions on a single workpiece.

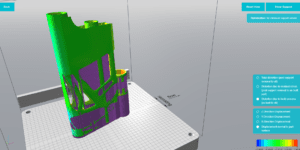

We’re Closer Than Ever to First-Time-Right 3D Metal Printing

In its drive to develop an end-to-end solution for additive manufacturing, Siemens Digital Industries Software offers tools that simulate the printing process at various levels. To minimize the expensive quality-refinement process, modules identify and correct areas of malformation and shrinkage.

Wayland Additive Awarded ISO 9001 Certification

The maker of NeuBeam says the certification objectively affirms the quality of their innovation in metal AM for production applications, as well as the company’s commitment to customer satisfaction.

CERATIZIT Wins Innovation Award

Luxembourg company is recognized for the additive manufacturing of carbide parts, providing solution for small volumes and high component complexity.

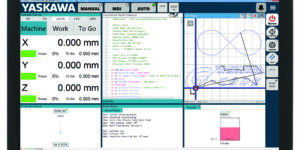

Software Enables Both Additive And Subtractive Applications

When coupled with an MPiec controller, machine tool builders and experienced CNC programmers can use Yaskawa Compass graphical user software to design HMI hybrid machines as well as 3D printing, shape cutting, and robotics.

3D Printer Processes Wider Range of Metal Materials

Unlike electron beam and laser powder bed fusion (PBF), Wayland Additive’s Calibur 3 uses NeuBeam technology, which focuses heat on the part instead of the process bed. As a result, the machine is able to process refractory metals and highly reflective alloys.