Additive Manufacturing Systems

Filter by Process Zone:

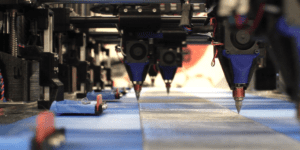

Versatile Powder Feeding in Automated Additive Manufacturing

The Twin 150 multi-process powder feeder from Oerlikon Metco can be run manually or completely controlled through a robot or process controller using UDP/IP or PROFIBUS protocols.

High Throughput 3D Metal Printing

The 3D Systems ProX DMP 320 from Methods 3D is ideal for higher volume production, with exchangeable manufacturing modules that support efficient powder recycling for rapid material change or replenishment so that shops can keep pace with demanding production cycles.

Automated Rapid Quoting and Model Building of Metal Printed Parts

The innovative and interactive Rapid Quote online service from Linear AMS permits users to upload 3D CAD models, explore design iterations and build cost models, assisted by a leading 3D printing service bureau.

Robotic Big Area Additive Manufacturing

The R-BAAM cell from Wolf Robotics is ideal for producing titanium aerospace parts and low volume, complex parts that can replace traditional, high cost, design-constrained castings in the steel casting sector.

3D Printing for Mold and Die Manufacturers

The Agie Charmilles AM 290 S Tooling machine from GF Machining Solutions integrates an EOS M 290 metal laser sintering system for producing mold inserts, linking software and automation with downstream machining and measurement for Industry 4.0 competitiveness.

Small Area Additive Manufacturing

The SAAM system from Cincinnati Incorporated automates part removal and uses NVCloud software to print parts anytime, from any cloud-connected device, with full workflow control in a shared-use environment.

True End-To-End 3D Printing Software

Netfabb from Autodesk has new simulation capabilities, hybrid manufacturing functionality and collaborative multi-head 3D printing so that users can test, optimize, prepare and print commercial-quality products, from CAD to finished part.

Continuous Innovation for Large Format Demands

Large-format Excel Series 3D printing machines from 3D Platform offer a parallel gantry configuration that can scale to growing application requirements and support simultaneous additive, subtractive, and robotics processes.

Raising the Bar in Yacht Racing

Metal 3D printing technology increases yacht racing performance through advanced rapid prototyping capabilities that allow this British yacht racing team to refine custom parts on demand and reduce their costs.

Back to the Future

Take a trip into process innovation with guest columnist Wes Hart of Imperial Machine & Tool, who shares some real-world insight about the journey of this 73-year-old machine shop as they incorporated metal additive manufacturing into a traditional machine shop environment.

Oerlikon Expands AM Business in U.S.

Their new state-of-the-art AM facility in Charlotte will offer end-to-end advanced component manufacturing.

Coldwater Machine Named Level 1 FANUC Integrator

This status opens up new automation opportunities for them in appliance, automotive, and aerospace applications.