Abrasives, Belts, Brushes, Grinding Wheels

Filter by Process Zone:

Weiler Donates to Habitat for Humanity

The company donated $10,000, products and labor to participate in the New Orleans Build-A-Thon.

Common CNC Grinding Mistakes

Proper grinding process parameters can eliminate a lot of the “black art” of CNC grinding. One critical variable is the grinding wheel being used and the dressing of the grinding wheel.

Finishing Welds in Stainless Steels

Here are some tips and guidelines for selecting and using the best abrasives products to create the desired finish.

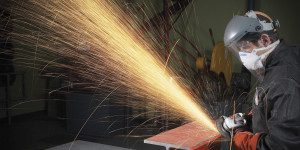

Grind It Out

Grinding represents a major part of shop costs. Take a look at the latest generation of flap discs, wheels, brushes and other tools that can help save time, reduce costs and improve the efficiency of your metal finishing operations.

Walter Surface Technologies Appoints New GM for Mexico

Pablo Rivero Torres now has general management responsibility for sales, marketing, operations and services in Mexico.

GCH Tool Group Relaunches Website

The redesign features intuitive navigation and browsing of products, descriptive photos and new content.

Weiler Launches Vending Program

Their power brushes, abrasives and other products integrate into coil or helix vending machines as an inventory control tool for shops.

Lean and Mean Surface Finishing

Investing in better consumables that significantly cut time and manpower costs is smart business. Selecting the right abrasive technology for specific applications to achieve speed and precision is one way to maintain your bottom line.

Automating the “Feel” in Deburring and Edge Finishing

Quantifying and adapting the “feel” of the abrasive against the part is a critical step toward successfully automating this labor intensive offhand operation.

Superior ID Surface Finishing and Deburring

The Flex-Hone® tool from Brush Research Manufacturing optimizes flexible honing lubrication, blends edges, and removes burrs – even from cross-drilled holes.

Nylon Abrasive Brushes for OD Deburring, Surface Finishing

NamPower technology from Brush Research Manufacturing is ideal for CNC machines, robotic arms, drill presses, lathes, and milling machinery.

Determining Actual Grinding Productivity & Cost

By evaluating and tracking abrasive performance, combined with taking the time to select the best abrasive for a particular application, job shops and production operations can identify opportunities to significantly decrease grinding costs and increase productivity.