Abrasives, Belts, Brushes, Grinding Wheels

Filter by Process Zone:

Osborn Launches End-User Van Initiative

The vans are designed to get their products into the hands of consumers in the Chicago metropolitan area.

Weiler Partners with Workshops for Warriors

They donated $25,000 to kick off a year-long campaign that will support machining and welding training programs at the nonprofit trade school.

Walter Surface Technologies Acquires Blackstone Supply Agreement

This deal allows Walter to accelerate their expansion in the U.S. by servicing Fastenal distribution of abrasives and welding consumables.

Three Ways to Optimize the Automated Brush Deburring Process

Want to reduce costs, improve process consistency, simplify part assembly, increase edge strength and create a more uniform finish? A wide range of operations are good candidates for a switch to automated deburring, and following these steps can help optimize the process for efficiency, quality and productivity.

Weiler Abrasives Appoints New Vice President

Jason Conner now oversees all of their sales operations in the U.S. and Canada.

How to Deburr Piercing Holes in Deep Draw Stamping

Precision Stamping Company had to remove the heavy burrs left on pierced holes in the stepped sections of a deep drawn spring cup that is flared at the top of a narrower body diameter. Instead of sending the parts outside for expensive thermal deburring or tumbling, they turned to a custom ball hone to do the job themselves. Here’s how they did it.

Rex-Cut Abrasives Celebrates Business Milestone

Honoring 90 years of engineered, refined, and customized cotton-fiber abrasive products for metalworking applications.

How to Improve the One Step Blending and Finishing of Metal

New flap discs from Metabo can grind down weld seams flush without gouging into the base material, including shaping fillet welds and grinding on edge in confined areas.

New Catalog of Abrasives that Increase Air Tool Productivity

The abrasives offered in the new, free Abrasive Catalog from Dynabrade compliment their high quality American-made power tools.

The Right Flap Disc Can Save Time and Money

Selecting the right disposable flap disc to use for a specific grinding, blending or finishing job also minimizes the risk of removing too much material and ensures the best possible finish. To maximize flap disc effectiveness and longevity, here are several key factors to consider for choosing the right tool for the job.

Walter Surface Technologies Launches Sweepstakes

Their ‘Grind to the Grid’ contest gives customers multiple chances to win great gear or a trip to the Daytona 500.

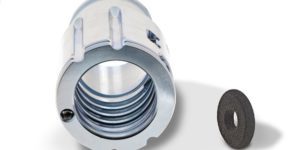

Superabrasive Wheels Grind Difficult Materials Substantially Faster

HPL Grinding Wheels from Meister Abrasives combine high-end CBN crystals fixed with durable, porous, intrinsically lubricated bonding matrix to allow substantially faster grinding of difficult materials.