Abrasives, Belts, Brushes, Grinding Wheels

Filter by Process Zone:

Flap Discs Provide Superior Stock Removal, Surface Finish and Service Life on Steel and Stainless Steel

The composite backing on POLIFAN PSF Z-TRIM flap discs from PFERD can be trimmed to extend service life and reduce time-consuming disc changes when surface grinding, weld grinding, blending, chamfering, and deburring steel and stainless steel.

Aluminum Grinding Reimagined

The Aluminator T27 cotton fiber grinding wheel from Rex-Cut Abrasives grinds aluminum fast and consistently without clogging and loading so that fabricators can grind and move on to the next step without stopping to clean the workpiece.

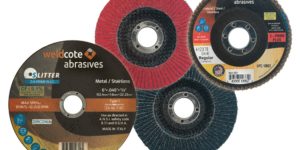

Flap and Quick Change Discs for Effective Grinding, Cutting and Other Applications

Metalworking abrasives from Weldcote include flap discs, quick change discs, Korner flap discs, resin fiber discs, flap wheels, cutting wheels, pipeline wheels and grinding wheels that are formulated for a wide variety of metals.

Cutting and Snagging Wheels for Metal Fabrication and Shipbuilding Work

To meet the increasing levels of cutting performance required in metal fabrication and shipbuilding applications, Weiler Abrasives added 38 small diameter cutting and snagging wheels for high-speed die grinders that provide longer life and faster cutting.

Air Tools Designed for Cobots

Outfitting a cobot from Universal Robots with a Dynabrade sander can automate and streamline repetitive or potentially unsafe processes to increase productivity, reduce injury and provide consistency of finish at all levels of production.

Go Where No Wheel has Gone Before

The innovative, three-dimensional coating on 3-in-1 Diamond Grinding Wheels from IPA allows back cutting, gully grinding and bead finishing in areas that other high-speed grinding wheels cannot access.

Precise Metal Cutting to Prepare for Welding

Precise cutting starts with preparation. Here are three tips to help you optimize performance and produce clean, smooth, straight cut lines in preparation for welding to minimize secondary operations like deburring and cleanup, and help operators achieve better weld penetration for higher quality welds.

Walter Surface Technologies Names New VP of U.S. Sales

Jeff Tisdell is now responsible for developing long-term, sustainable sales growth through strategic planning.

Weiler Abrasives Gives Big Donation to United Way

Employees and the company give over $68,000 to help local residents facing poverty.

Weiler Abrasives Appoints New Director of Sales

Jennifer Hawkins now leads their district sales manager team for the West region.

Weiler Abrasives Rebrands European Division

SWATYCOMET d.o.o. is now Weiler Abrasives d.o.o. and Toroflex GmbH is now Weiler Abrasives GmbH.

CBN Abrasive for Difficult-To-Finish Materials

To Flex-Hone difficult-to-finish materials such as high nickel alloy steels, Monel, Inconel, Incoloy, Hasteloy, Invar and Rene, cubic boron nitride abrasive from Brush Research combines the highest hardness with excellent toughness for optimum surface finishing.