Vision Measurement Systems Address a Broader Range of Inspection Needs

Coordinate Measuring Machine’s (CMM’s) and vision systems enable advanced analytics, and quick, precise and repeatable measurements.

Posted: January 20, 2025

The synergies created when coordinate measuring machines and vision systems are combined with advanced software are fueling transformative change when it comes to quality control in manufacturing processes.

Cutting-edge Automation and Precision

HEIDENHAIN CORP.’s (Schaumburg, IL) commitment to precision and automation is shown through the debut of the VT 122 measuring camera, an all-in-one system that combines tool presetting, microscopy and visual inspection. This innovative product allows for comprehensive tool analysis within the machine envelope, reducing downtime and enhancing productivity. By enabling automated tool measurement and wear inspection, the VT 122 contributes to lowering the total cost of ownership by extending tool life and increasing efficiency.

Measuring and Visualization Software for Quick Analysis and Data Evaluation

Blum-Novotest Inc.’s (Erlanger, KY) now offers the latest version of the LC-VISION measuring and visualization software. The application, which was developed specially for the laser measurement systems from BLUM, has been adapted even more closely to the needs of users and its usability has also been improved. For instance, the free standard scope has been expanded to include the “ToolControl” and “Stability” functions. ToolControl is an intuitive application which even users without NC programming knowledge can use to quickly and easily generate measuring sequences for the most common measuring tasks.

The user can visualize measuring sequences for tool length and radius, including the tool-specific wear limits, directly on the control screen and take appropriate action. The stability function is used to determine the thermally stable spindle state for high-precision machining, to name just one example. If a machine is in the warm-up phase, the spindle elongation is measured at speed and the length value in the tool memory is updated after the thermally stable state is reached. For ambitious measuring tasks, there are also optional technology cycles available such as “ToolControl Advanced” or “SpindleControl.”

Improved Measuring Software Promotes Safety and Productivity

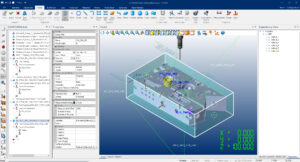

LK Metrology, Inc.’s (Hudson Heights, MI) latest version of its measurement, programming, simulation, analysis and reporting software, CAMIO 2024, features upgraded performance in several key areas.

Clearance Box is a new path planning aid that simplifies and speeds programming by automatically adding clearance moves to prevent the sensor, whether a tactile probe or laser scanner, colliding with the workpiece when moving between measured features or during head repositioning. Working alongside this feature is Auto Sensor Selection, which raises the efficiency of an inspection program by minimizing the total number of probe positions required to measure a part without the programmer having to work out the optimum sequence.

Finally, a new stand-alone utility enables settings from one CMM running CAMIO 2024 to be copied to another. This is useful to users with multiple CMM installations, whether in the same location or spread across different sites, where settings need to be duplicated to harmonize quality processes. Copying CAMIO setting also creates a valuable back-up for data security. CAMIO 2024 encourages experienced and novice users alike to drive inspection graphically from a CAD model, either online or offline, although teach and learn using a CMM hand box is available.

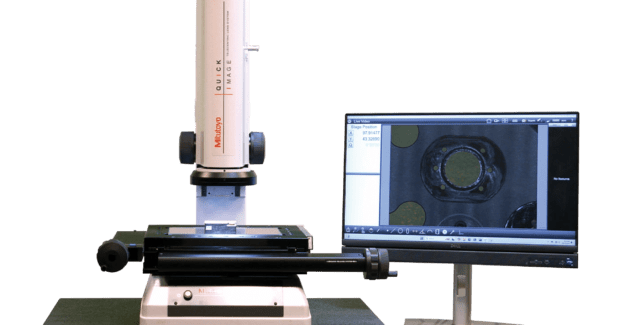

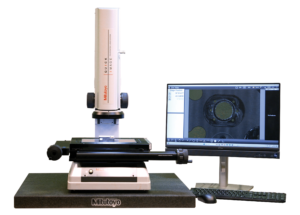

Vision System Elevates the Efficiency of Non-contact Measurements

Mitutoyo America Corp. (Aurora, IL), a leader in precision measuring instruments, announces the integration of the powerful Metlogix M3 software into the Mitutoyo Quick Image 2D Vision Measuring System. This latest enhancement promises to elevate the precision and efficiency of non-contact measurements. The integration of Metlogix M3 software transforms the Quick Image system, known for its superior accuracy and ease of use, into an even more robust tool for non-contact measurements. The M3 software introduces a highly intuitive, icon-driven interface designed for simplicity and speed.

Key Features of the Metlogix M3 Software with Quick Image include:

- Pattern-Based Measurements: The M3 software provides innovative pattern-based tools that simplify the measurement process, making it easy to measure multiple points in a single action. This dramatically reduces setup time and increases productivity.

- Advanced Video Probes: The software’s advanced video edge detection tools, such as EyeMeasure™ and MeasureLogic™, enable fast, accurate edge and feature capture. The VTouch™ probe brings unprecedented functionality by allowing video-based touch probing for quick acquisition of individual points.

- Field of View Measurement: Metlogix’s powerful Field of View functionality automates part measurements by simply placing multiple parts in the camera’s view. The system detects, measures, and displays results without the need for operator intervention, streamlining the inspection process.

- SuperImage Stitching: For larger workpieces up to 400 mm, the Quick Image system utilizes an ultra-long 90 mm working distance to capture and stitch multiple frames into a single image with Metlogix’s SuperImage feature. This function enhances accuracy and clarity over larger areas while allowing flexible, soft fixture setups for repeated measurements.

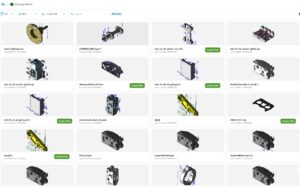

Automating CMM Programming

Hexagon’s Manufacturing Intelligence (North Kingstown, RI) launched Metrology Mentor for the first time globally at IMTS 2024, a revolutionary new SaaS application that automates the creation of measurement programs. A software solution powered by the company’s Nexus digital reality platform, Metrology Mentor delivers rapid, reliable and repeatable measurement routines so manufacturers can speed up time to market without risking quality issues. Metrology Mentor addresses a critical pain point in manufacturing: the time-consuming and variable process of coordinate measuring machine programming. By leveraging advanced algorithms and artificial intelligence, the software automates the creation of measurement routines directly from computer-aided design data, adhering to industry standards such as the International Organization for Standardization and the American Society of Mechanical Engineers. Metrology Mentor eliminates the need for manual programming, reducing human errors and ensuring consistency across all measurement processes.

Hexagon’s Manufacturing Intelligence (North Kingstown, RI) launched Metrology Mentor for the first time globally at IMTS 2024, a revolutionary new SaaS application that automates the creation of measurement programs. A software solution powered by the company’s Nexus digital reality platform, Metrology Mentor delivers rapid, reliable and repeatable measurement routines so manufacturers can speed up time to market without risking quality issues. Metrology Mentor addresses a critical pain point in manufacturing: the time-consuming and variable process of coordinate measuring machine programming. By leveraging advanced algorithms and artificial intelligence, the software automates the creation of measurement routines directly from computer-aided design data, adhering to industry standards such as the International Organization for Standardization and the American Society of Mechanical Engineers. Metrology Mentor eliminates the need for manual programming, reducing human errors and ensuring consistency across all measurement processes.