Leverage the Flexibility of AI to Quickly Adapt to Changing Demands

When you move past the hype surrounding the promise of AI you will find it truly delivers real value to your shop. Before diving in, make sure AI is the right tool to fix your challenges.

Posted: January 15, 2025

With the onset of a New Year comes the sense of new possibilities and opportunities. The U.S. presidential election is behind us. The ISM’s November Manufacturing PMI registered at 48.4%, 1.9 percentage points higher than the previous month; the overall economy continued in expansion for the 55th month after one month of contraction in April 2020. The ISM also reported that the New Orders Index returned to expansion, albeit weakly, after seven months of contraction, registering 50.4%, 3.3 percentage points higher than recorded in October.

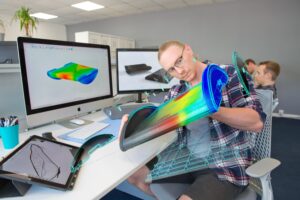

This all foreshadows the upcoming success expected regarding the metalworking industry, which is riding the wave of excitement and innovative ideas generated at amazing industry trade shows held in the fall of 2024, such as the International Manufacturing Technology Show (IMTS) and FABTECH. These events reinforced and stressed that automation, robots and cobots, and artificial intelligence (AI) will continue to drive decision-making by metalworking industry members.

With AI, data is easily made available, but more importantly are the numerous ways your shop can implement the data captured to benefit production efficiencies. The advantages to metalworkers are just beginning. But wait a minute —let’s pump the brakes — shop owners wonder if AI will deliver real value and if its capabilities will solve manufacturing challenges. The answer is a resounding “yes” as manufacturers, who are typically slow to implement new technologies, are embracing AI and reaping its promise (76% of respondents to Autodesk’s 2024 State of Design & Make survey stated they trust the use of AI in their industries.)

Just a few of the benefits include the time savings on functions that used to take hours or days, minimizing errors and reducing waste, improving sustainability throughout the operation, and tackling backlogs in order to be more productive and profitable, among other advantages.

One monumental advantage is how AI frees up your skilled team members to work on more projects, including new business opportunities. For example, with AI based in the cloud, stacks of drawings can be automated resulting in an 80% savings of typical processing time. AI frees up your teams to do work that is more creative. And it minimizes errors.

Additionally, AI tools at work in manufacturing solve problems your shop is aware of, and also solve problems your shop has never considered as being a problem. AI is truly transformative and innovative, Autodesk’s Clinton Perry tells us in this issue’s cover story: “State of the Industry: Artificial Intelligence Revolutionizes Manufacturing.”

While AI can’t provide solutions to all of your processes, for instance, AI isn’t capable of driving the most complex machine types such as a 5-axis milling machine, Perry noted, it is only a matter of time. The crucial point is AI tools might get you 80% of the way in automating processes. That is a ton of savings for your shop. And a great way to ring in the possibilities of the New Year.

www.fabricatingandmetalworking.com