Company Boosts Efficiency with Automated Deburring and Shot Blasting for Excavator Bucket Parts

Since July 2024, MARTIN GmbH has utilized a Teqram robot to fully automate deburring and shot blasting, which has drastically improved production efficiency and enhanced working conditions for employees.

Posted: December 10, 2024

Previously, the sheet metal parts for excavator buckets at MARTIN GmbH in Ludesch, Austria, were manually processed with chisels and angle grinders – an exhausting, time-consuming task. Since July 2024, the company has utilized a Teqram robot that fully automates deburring and shot blasting. This shift has drastically improved production efficiency and enhanced working conditions for employees.

As one of Austria’s largest manufacturers, MARTIN GmbH, a subsidiary of Huppenkothen, produces around 20,000,excavator attachments annually, including quick-change systems, buckets, and hydraulic couplings. Meeting this volume demands optimal efficiency at every stage of production.

Manual Processing: High Physical Strain

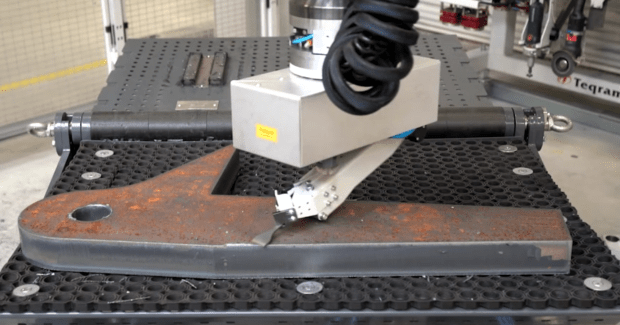

Sheet metal blanks, ranging from ¼” up to 3” in thickness, are cut using an advanced plasma and flame-cutting system. Previously, several employees were responsible for preparing these parts by removing slag with chisels and grinding surfaces with angle grinders. This method was not only labor-intensive but also physically demanding, with some parts weighing over 100 lbs. Employees had to endure long hours of handling vibrating tools while turning heavy components, contributing to high physical strain.

Addressing Labor Shortages with Automation

“Finding workers for such heavy, monotonous tasks was already challenging,” says Herwig Koch, Operations and Technology Manager at MARTIN. “On top of that, sick leave frequently disrupted operations. With the Teqram robot, those issues are now resolved.” The turning point came when MARTIN discovered Teqram’s revolutionary system at EuroBLECH 2022. “A robot that operates without programming? That immediately caught our attention, given our diverse product range,” Koch recalls.

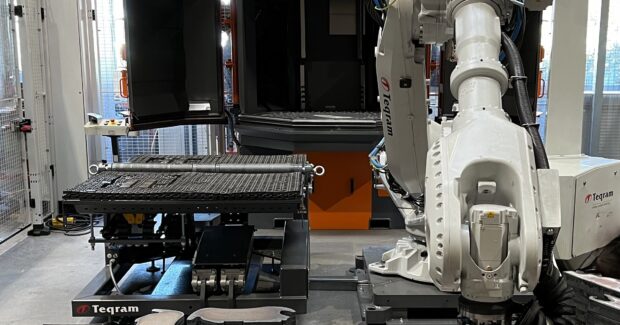

Teqram EasyGrinder and EasyShotblast: Flexible, Precise, Fully Automatic

Teqram’s EasyGrinder offers maximum flexibility. Operators place flame-cut parts on Euro pallets, choose the desired processing quality, and the robot handles everything from slag removal to edge grinding or creating a 1/16“ radius. Equipped with auto-changing tools, the system even turns and grips the parts, ensuring seamless, fully automated processing. After deburring and grinding, a Rösler rotary table system takes over for shot blasting. The Teqram robot automatically arranges the parts for optimal blasting efficiency and restacks them on pallets after processing. The entire process is executed without any programming or manual intervention, delivering ready-to-install components.

Vision Technology: No Programming Needed

What sets Teqram apart is its advanced vision technology. Using 3D vision sensors and the EasyEye system, the robot identifies the contours of the workpieces without needing CAD drawings. It calculates the weight and selects the appropriate gripper based on the material and geometry. The EasyFlipper then turns the part for complete, efficient processing on both sides. Teqram’s ‘no programming required’ approach makes these robotic solutions perfect for companies like MARTIN that handle small to medium batch sizes with frequent workpiece changes. Avoiding time-consuming programming ensures maximum productivity.

Enhanced Efficiency and Working Conditions

By automating production with Teqram, MARTIN has significantly optimized its processes, ensuring high-quality, reliable products while improving working conditions. Automation has also made MARTIN a more attractive employer by alleviating the physical burden on its workers.

Teqram Vision-Guided Robotics

Teqram’s modular robotic systems incorporate cutting-edge components like 3D vision systems, intelligent grippers, and AI-driven controls. Solutions like the EasyGrinder and EasyShotblast, deployed at MARTIN, are part of a larger suite that also includes systems for loading, unloading, deburring, and leveling machines.