CNC Machining of a Lamborghini Huracan Evo 2 Super Trofeo Model

Blaser Swisslube, in collaboration with its industry partners, demonstrates machining strategies for complex parts.

Posted: December 6, 2024

Blaser Swisslube, in collaboration with its industry partners, embarked on a unique and ambitious project: CNC machining a model of the Lamborghini Huracan Evo 2 Super Trofeo race car. This endeavor was carried out alongside Nigel Bailly, a Blaser-sponsored racecar driver in the international Lamborghini Super Trofeo Series.

“From the beginning I thought this was a superb idea! The challenge to match the car and machine it at 1/8 scale shows the amazing abilities of the team at the Blaser technology center. I’m so excited to see this piece of art in person!” said Bailly.

The partnership brought together machine tool OEMs, fixture and tooling suppliers, and software and programming experts. Each company contributed technology and expertise to over 40 projects in the past year. The collaboration culminated in this exciting Lamborghini video project, shared across social media platforms, reaching a wide audience of machining and metalworking enthusiasts.

One month of designing and programming

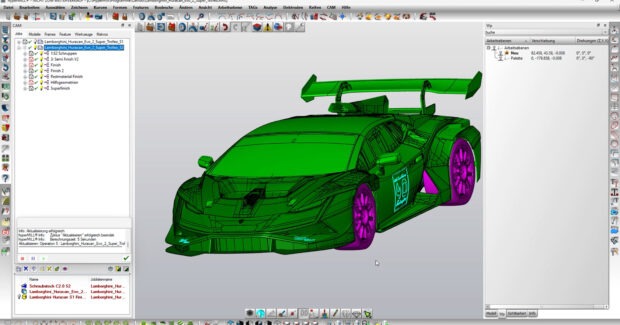

Blaser’s in-house machinists began by analyzing photos and videos of the racecar. Using hyperMILL software from Open Mind Technologies, the team meticulously modeled the car and developed the program required to machine it from a solid block of 6082 aluminum.

Tool path clearance was a particular challenge. The 2024 release of hyperMILL saved enormous amounts of time by seamlessly linking CAD functionality to CAM programming. The intricate process involved one month of designing and programming, ensuring every detail of the race car was accurately captured.

Achieving complex angles, precision and realistic surfaces

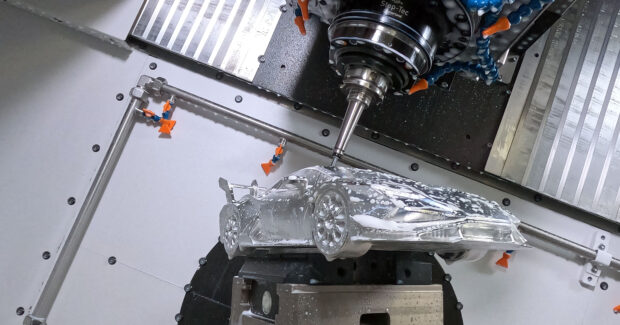

Once ready, the material was loaded into a GF Mikron Mill (E 700 U) at the Blaser technology center. The 5-axis GF mill, equipped with a tilting, rotating table with a range of -65° to +120°, was essential to achieving the required precision and complex contours of the car.

Workholding was also tricky due to the model’s intricate shape and small size. Gressel AG provided a modular C2.0 series centric vise system offering maximum versatility while maintaining complete stability of the workpiece – imperative for achieving complex angles and precision.

Specialized tool holders were applied to various tasks. The REGO-FIX powRgrip system with Micro-Friction Dampening technology was used to reduce vibrations throughout the tool assembly. The powRgrip system improves surface finish, extends tool life, and reduces spindle wear. BIG Daishowa’s Shrink Fit Holder Slim arbors, with their small nose diameter, enabled access to tight areas with minimal clearance.

The combined efforts from each of the partners came together to ensure every element of the Lamborghini Huracan Evo 2 Super Trofeo was faithfully recreated. To add realism, the machining experts at Blaser Swisslube used various surface finishing techniques to replicate the car’s distinct textures like carbon fiber and aluminum trim. Note the reflective surface finish of the model car’s windows and mirrors, which required a specialized diamond-bit finishing tool from Dixi Polytool.

Blaser’s B-Cool MC 660 metalworking fluid also played a pivotal role in the final result. Selecting the right coolant for the application allows higher feed rates, reduces tool wear, and delivers exceptional surface finish. The Rotoclear S3 self-cleaning spinning window allowed a perfect view of the work envelope, and the C2 camera system captured every move in high definition.

The power of focused partnerships

“The Lamborghini project is a testament to the power of collaboration and the importance of focused partnerships among industry specialists,” said Marc Blaser, CEO of Blaser Swisslube. “When experts in an industry come together with a shared vision and commitment, the potential for innovation and excellence is unparalleled. These collaborations not only push the boundaries of what is possible but also set new standards.”

As manufacturing challenges become increasingly complex, the value of these synergistic partnerships becomes evident, highlighting the need for ongoing cooperation and mutual support to drive progress and success.