Welding Technology: Robotics, Automation and Cobots

Moving beyond high-mix, low-volume welding work, cobots are more and more suitable for laser welding, becoming increasingly more portable, and are incorporating coordinated motion to optimize cycle times.

Posted: November 16, 2024

Industrial welding cobots are multipliers, enabling fabricators to develop a cooperative workforce, assisting them in overcoming labor shortages. “The cobot is a tool for the welder,” said Dan Colvin, ESAB’s vice president for North America Robotics & Digital Solutions. “It is not a replacement for the welder.” Efficiencies are gained with cobots because your shop is able to basically double, triple or quadruple the number of hands an experienced operator has. The operator can run two or three cobots, instructing them what to work on and how to work on it, Colvin added, while the operator works on other functions.

Fabricators no longer need to turn away work because they are short staffed. Universal Robots and its extensive network of partners, as an example, have met with customers that had to turn work away because a project required 10 welders, and they only had five welders. By deploying cobots, companies are able to increase productivity anywhere between 4x-to-10x, expanding their capacities and winning new business.

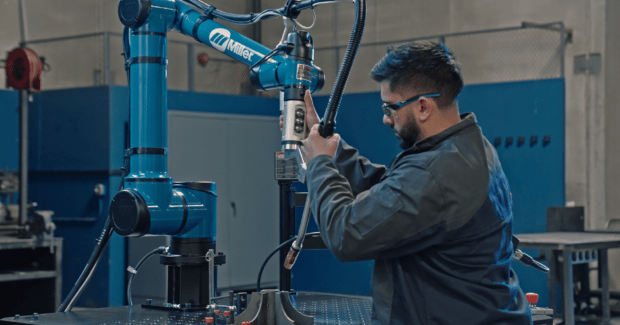

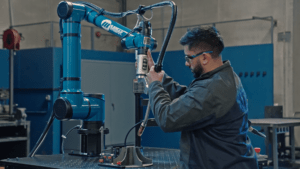

These automated cobot systems provide shops with a variety of ways to be productive, providing more resilience and more throughput. “The reason they [cobots] are disrupting [the welding sector] is the industrial robotic platforms have grown long in the tooth,” said Ross Fleischmann, marketing manager of Miller Welding Automation for Miller Electric Mfg. LLC.

Industrial robot companies have been competing against each other with old interfaces and programming systems that have been around for decades. There wasn’t a lot of innovation to borrow from or incorporate into those business models, Fleischmann noted.

“And then all of a sudden, the cobots show up and all these new upstart companies start innovating with new technology, with things like using your cell phone or using apps, local apps, or just the iconography of your user interface,” Fleischmann said.

These advances have created a new learning environment and user environment. Using cobots has become intuitive as using an iPhone, said Will Healy, global industry leader-welding, Universal Robots (UR). UR introduced the world’s first commercially viable cobot in 2008 and offers a product portfolio that includes a range of reaches and payloads. Through the extensive UR+ partners program, companies are developing innovative ways and products to use with UR’s cobots. “The mission is automation for anyone, anywhere,” Healy said. “Why cobots are so interesting is because they are actually easy. You don’t need a robot programmer to use most cobots.”

Cobots are increasingly intuitive — if you can create a song playlist on a mobile device you can program a weld sequence using an app on a mobile device. The ease of use of these systems is something cobot manufacturers, integrators and welding equipment manufacturers continue to improve on in order to overcome the ongoing skilled welder shortage. The American Welding Society projects the United States needs 330,000 new welding professionals by 2028 — 82,500 welding jobs need to be filled annually between now and 2028.

Fabrication shops aren’t the only ones taking notice of the advantages of cobots. The education and training community is taking note when it comes to instructing the next generation of welders. Because cobots are easy to use and intuitive tools, educators and trainers want to align their curriculums to include cobots, Fleischmann noted. Welding is complex, with different welding processes. “When you are welding manually with all those processes, the outcome or the results are inextricably tied to the manual dexterity of the person,” Fleischmann added. “Or their ability to move that torch and control these factors, the work angle, the travel angle, the stick out and the travel speed. But with automation you get a clear distinction between the two, because now I can have my robot or my cobot take care of all that manual dexterity stuff and make it perfect.” Cobots help welding students understand the different processes because they can see the differences when they do it with automation,” Fleischmann noted.

Colvin also pointed out that utilizing cobots enables you to attract the next generations of welders because you are modern, up to speed and forward thinking using the latest technologies. Cobot technology fits right into their comfort zones, which is video games and mobile devices and computers, Colvin said. ESAB offers an app where fabricators can use mobile devices to work the cobots. “We are going to give you the tools that help you do your job better, safer and more comfortably,” Colvin said. Working with experienced welders, new welders are developing new ways to accomplish welding tasks. And older workers are extending their careers by using cobots due to the fact that automation lessens the physical toll of the job. Working together, fabricators can utilize the cobots to solve existing problems, and even determine alternative ways to solve other problems to streamline the production process even further.

Yaskawa Motoman’s app is called Weld Builder, which features a functionality called Weld Editor, which is icon driven. “So instead of a bunch of words on the screen, it features icons that represent the movements,” said Joshua Leath, welding product manager, Yaskawa America, Inc.’s Motoman Robotics Division. “They will continue to evolve as we add different sensor technologies and features to that.”

Cobots Allow You to use Talent Wisely

By utilizing user-friendly cobots, fabricators find the most success producing parts that result in easy “wins.” For example, select the simple, boring, repetitive welds, straight line welds and circular welds. By doing so your shop can use a skilled welder’s talents wisely on unique projects because you are automating whatever work you can. One welder is able to manage several cobots, which creates a force multiplier in the workforce.

Colvin cautioned that your shop will not fix a welding problem by throwing a robot at it — “that is not how automation typically works best,” he said. “It’s a journey.” Solve one problem and see where the next problem arises. “Can you grind, sand or weld; can you pick and place?” Colvin asked. The process needs to be a total package of how to make things better.

“The reason welding with a cobot is so interesting is you reach out and grab it, you put it where you want it, you teach it how the weld is going to build, and then the robot does that,” Healy said. “It utilizes the skill of the welder, but it gets rid of the boring, repetitive tasks.”

“You have gone from big expensive automation solutions down to a single cell, single robot, something that is very flexible,” Leath added. “You can duplicate the efforts of humans. They are nice because you lead to teach and grab the robot and move it into place. You don’t have to understand XYZ coordinate systems or anything complicated to program these robots.”

For MT Solar in Charlo, Mont., a company that designs and manufactures mounting structures for solar modules of all sizes, a Vectis Cobot Welding Tool powered by UR handles a wide range of welds, enabling quick changeovers and optimizing production. With the cobot, MT Solar overcame labor shortages and freed current staff from repetitive welding tasks while successfully handling a 300% surge in demand.

“We have many products that go together — think of us as a ‘Solar Ikea,’ if you will — where all the pieces have to be assembled in the field,” said Travis Jordan, owner and president of MT Solar. “If I don’t have all the other parts that go with it, I can’t ship anything.” Because cobots offer safe human-robot collaboration in proximity without fences, it further increased the appeal of cobot-powered welding solutions for Jordan. “When I zoomed in and discovered Vectis Automation’s Cobot Welding Tool, it became obvious that this combination was the right way to go,” Jordan said. “You can work right beside the cobot as it is moving and welding. My guys can have their hood down and be right there, changing parts out with no safety guarding and no concerns about safety. They’ve been very, very comfortable working with it.”

What’s Next for Cobot Technologies

Cobots will continue to be a contributor to the welding industry, providing bench strength to welders of all skill sets. Cobots solve problems, but of course, not all problems. Cobots allow shops to address welding challenges and explore other capabilities, Colvin noted.

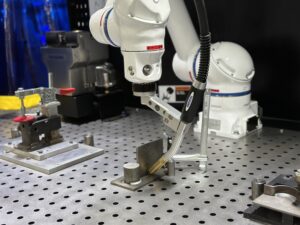

With cobots, what began as an automation tool to assist with repetitive welds, consistency and predictability in high-mix, low-volume work has evolved to major shifts such as supporting the acceleration in the adoption of laser welding, Healy said. The reason laser welding is so interesting is you get TIG quality welds, “but you get them four times as fast,” he said. “Of course, every weld is different and every build is different. But generally, that’s the reason you are seeing laser welding come up.” Whether that is for deep penetration into big parts or for thin stainless steel aluminum parts, as examples.

Much like traditional welding, laser welding requires a steady hand to make a quality repeatable weld over and over with a hand laser welded part. So, the collaborative robot, with its touch to teach and other advantages, enables quality reliability in welding those parts.

Longer reach cobot arms are also making an impact in the welding sector, particularly when it comes to the welding of construction equipment. For a Yaskawa Motoman customer, a construction equipment manufacturer found that a fabricator can weld about 2’ at a time, where longer reach cobots are able to complete 6’-to-8’ of weld at a time on a single path. “The customer didn’t have a lot of start and stops, which have the potential for porosity and pitting and defects in the weld,” Leath said. “They get a much higher integrity weld by using the longer reach cobot arm where humans are limited with their reach.”

Healy also noted another trend with cobots and that is in regard to the portability of the cobot arms themselves — taking the cobot to where the work is located. An example is Carriere Industrial Supply (CIS) in Sudbury, Ontario, Canada, which is producing a three-story mining truck, where it is not possible to bring the work to the fabricator. The MIG welding process is applied to massive parts weighing more than 15 tons on the bodies of heavy-duty mining trucks; workpieces that can’t be fixtured inside a traditional robot cell.

That required CIS to bring the robot to the workpiece, rather than the other way around. Unable to find a standard solution, the CIS team developed a custom welding skid that can be moved with a forklift to wherever the welding robot is needed. The robot is mounted on a lift to create a seventh axis to reach the entire weld on the side of a truck body. The relatively light weight of the UR cobot arm allowed CIS to develop this innovative approach.

Leath concurred that portable cobots are opening up new environments. “I would say there are a lot of untapped areas because of the size of the parts, such as shipbuilding, which is the largest welding industry, hands down,” he said. “Very little shipbuilding is automated. It is something that companies have tried for many years. Leath said the industry is getting closer to being able to use automation to handle these very large vertical welds because cobot arms are getting lighter, with portable equipment to move around in that space.

It will also require teaching a robot to look for a seam rather than teaching where the seam is at, so it would call for vision or another sensor technology mixed with some type of model that is going to tell the fabricator where to weld.

Miller Electric will also soon be offering a portable cobot that will be on a pedestal or a cart with wheels, Fleischmann adds. Miller Electric will also be offering the Builder, which will debut in 2025, and offer the bits and pieces of a cobot welding cell, so that customers can assemble the cobots how they want them on their table or fixture, or within their environments, Fleischmann noted. So, the fabricators don’t have to work with an integrator and can integrate the cobot themselves. “You don’t see that anywhere in the marketplace except with rentals,” Fleischmann said.

Yet another trend to watch for in the coming year is the increase of coordinated motion applications for cobots, which enable extended reach, such as the use of linear rails, supporting the production of parts for use in construction or bridges, Healy said. This hasn’t been possible with cobots before and has been common in traditional welding. “The ability to get an extended reach for the robot to be able to position a product is really important for welding and really blending the cobot into traditional automation,” Healy added.

When it comes to handling heavier payloads and the portability of cobots, Colvin said that companies are coming up with creative ways of deployment, whether they are hanging cobots upside down, putting them on walls or placing them on magnetic bases. “We want to make it so that you can take the cobot to the part so we are going to add axes,” he said. “So, picture a cobot on, for a lack of a better term, a rail or roller coaster and it just runs around welding.”

THG Automation, a UR partner, has implemented a new feature in its cobot welding solutions, the coordinated motion functionality from UR. It synchronizes motion between the UR cobot and one or more external axes, optimizing cycle time significantly and following precise toolpaths. It also supports welding odd-shaped and cylindrical parts that are difficult to efficiently weld, even with cobots. The coordinated motion functionality is predicted to bring about double-digital improvements in productivity.

Cobots are also increasingly incorporating vision systems and AI into their platforms. “We have been processing images for a very long time, 30 plus years, but the AI tools are bringing down the price point and raising the speed at which we can process images,” Healy said. Prior to this, it required a lot of money and a lot of time to do those things.

“AI is a big deal right now, so a lot of the sensor technologies are creating data for some type of AI model to be able to complete a weld job,” Leath said. He pointed out that a part may look pretty much the same but can change in size or action, and the fabricator knows the weld seams are going to be in a particular area. The operator can train the model to look for the weld seams without human intervention, while the operator is verifying the parts.

Leath said companies like Path Robotics, ABAGY and NOVARC Technologies are using different types of sensing technologies, whether it is a camera or a camera on the weld puddle to determine where the track for the robot should be.

UR offers an Artificial Intelligence Toolkit, which teaches optimization of torch angles, weld paths and more. Teaching optimization through AI will also be important to educational and training partners who are instructing the next generation of workers.

Cobots can be force multipliers in your shop at a time when the need for welders in the United States is in high demand. The increasing ease of use of cobots, complete with additional and future functionalities and capabilities such as portability and coordinated motion, will assist in streamlining your processes and open up capacity to win new work.

Just make sure you connect with a trusted partner that can readily and immediately answer your questions. Buy your cobot from a major brand that has extensive service and support. These companies will partner with you to incorporate the next evolution of welding cobot functionalities, including portability, new ways to create weld sequences from devices, and advances in coordinated motion.

www.esab.com

www.millerwelds.com

www.motoman.com

www.mtsolar.us

https://thgautomation.com

www.universal-robots.com

https://vectisautomation.com

{Sidebar}

Cobot Welding Summit Spotlights 365-Day Transformation and Collaboration

The road to welding automation is a journey, filled with solutions to welding challenges that result in major increases in productivity, cost savings, and collaborating with partners that are vested in your success.

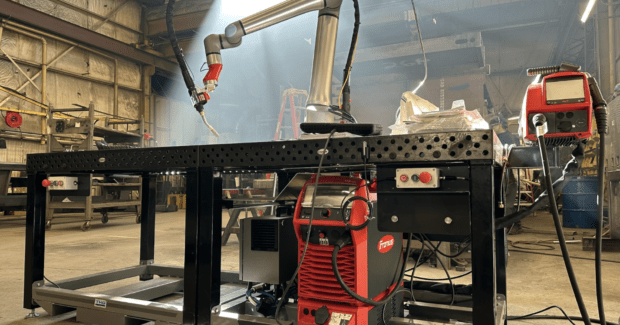

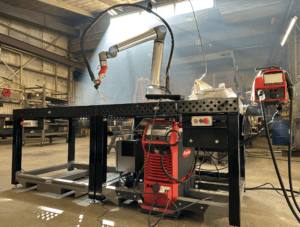

“Flextur’s Cobot Welding Summit,” held on September 4 in partnership with Modine Manufacturing Co.’s Jefferson City, Mo. facility highlighted why a global manufacturer continues to experience success utilizing cobots in its welding operations. Modine Manufacturing is a more than 100-year-old thermal management company supplying commercial, industrial and vehicular markets with systems and solutions to manage heating and cooling and improve air quality.

Flextur, based in Dalton, Ohio, is a U.S. manufacturer of welding and work cell products, including cobot welding systems. Flextur’s advanced Cobot Welding System is equipped with quick-change fixture plates and has proven to boost productivity by more than 300%. By partnering with Modine Manufacturing’s Jefferson City facility, Flextur’s team assisted the company as it effectively put three cobots to work, which a year earlier had been sitting in a corner in the facility. The partnership team integrated the cobots into Flextur’s cobot welding systems to create an accurate, repeatable and productive welding cell.

Flextur offered a partnership that was much more then designing and building fixtures for Modine Manufacturing, noted Glenn Zimmerman, manufacturing engineering manager for Modine. “They would come in here and use our parts and our products and their equipment to show us and give us that vision of how to get started,” he said. “And from there, it snowballed.” He added that the return on investment for these machines was much more than just the months that it took to pay back the equipment. Modine Manufacturing’s capacity increased by 3x, the ergonomic friendly process took less of a toll on operators, and precious floor space was saved. “Now, with that same floor space we could get three times the output and not need to expand,” Zimmerman noted. “And our square footage is valuable right now.” Added Modine’s plant manager Chris Crowe regarding the investment in cobots and how it has impacted the company and the influx of new business: “It has definitely impacted us with the savings of $700,000 or more in labor.”

Rounding out the Flextur cobot summit was an evening Q&A session, moderated by incoming American Welding Society Board Member, Karen Gilgenbach, who is the vice president for gas company Matheson’s north zone. Crowe and Flextur’s CEO Daniel Wengerd answered questions such as providing insights into what things really contributed to the culture of collaboration and openness between the companies. They also addressed how they achieved buy-in regarding cobots from team members and what challenges they had to overcome to gain that buy-in. Crowe and Wengerd also addressed how they decided what welds should be automated, as well as how the implementation of cobots changed upstream and downstream processes.

“The biggest success for this whole project, for me, is us thinking differently and doing something different than all of our other competitors,” Crowe said. “And with that came gains financially where we’re performing well, our customers are happy, and we’re delivering more product on time.”

Added Wengerd “it behooves all of us as we look at the industry to look around the corner — what’s coming? The market is changing rapidly and unless we are agile and are adapting, we will be left behind. So, that’s why we need each other. We just simply won’t figure it out on our own. We need the industry experts.”

www.flextur.com

www.modine.com