Smart Tool Dispensing and Configurable Storage Systems Elevate Workflow

Tool cabinets and material storage systems enhance operations by providing smart, secure, and easily adjustable tool and material storage.

Posted: November 16, 2024

Solutions for handling tools, and metal products offer metalworkers flexibility, and space-saving design for streamlined production environments.

Perfect Synergy in the Provision of Materials

KASTO (Export, PA and Mississauga, ON) and SEW-EURODRIVE, located in Bruchsal, Baden, Germany, have developed a complete solution that seamlessly integrates metal saws and storage technology to supply the drive technology specialist’s production with semi-finished products from a centralized location. No matter if the batch size is 1 or 10,000, the unique system organizes each process step fully automatically. SEW-EURODRIVE is one of the global market leaders in the drive technology/drive automation sector.

During the planning and implementation of a new 4,000-square-meter warehouse for SEWS, KASTO and SEW combined a UNICOMPACT honeycomb storage system with 5,140 storage spaces for cassettes weighing up to three tons with a KASTOcenter sawing center containing 450 spaces for individual bars. Two compact overhead gantry cranes (OGC) transport the material to the seven lengthwise installed outfeed stations KASTOpick split, where it is separated by lifting mechanisms and transferred to the infeed roller conveyor of the saw. The cassettes are fitted with inclined floor bars to ensure the material is placed in a defined position. Three additional stations can be connected to the system if required.

KASTO has implemented a demagnetization system in the incoming goods department, where the crane unloads the entire bundle from the lorry onto a material buffer chain conveyor. Depending on the barcode specifications, the system stores the goods directly in the cart storage or transports the bundle into the bypass to the demagnetization coil. The transport cassette moves through an alternating magnetic field, which automatically demagnetizes the entire material. The overhead cranes then stores the treated steel in the UNICOMPACT.

KASTO sawing centers are a combination of buffer storage and CNC sawing machines. SEW utilizes the fully automated KASTOcenter varioplus 2 cantilever storage system. With this system, a computer-controlled OGC transports individual bars to the integrated saws. To save space, KASTO designed the sawing stations as tunnels directly into the shelf block of the UNICOMPACT storage system. Eight fully automated KASTOvariospeed C 18 production circular saws cut through workpieces up to 180 millimeters in diameter.

Safety Cabinets Keep Contents Safe

DENIOS’ (Louisville, KY) fire-rated storage cabinets provide 90 minutes of fire resistance, making them ideal for safe, secure storage of flammable and combustible liquids. Independently fire tested, FM 6050 approved, and UL and ULC listed, these safety cabinets ensure compliance with the most stringent safety regulations and quality standards for the storage of flammable liquids. They conform to NFPA 30 and NFPA 1 codes, and OSHA standards, and meet the fire testing regulations of EN 14 470-1. In addition to conforming to construction specifications and labelling requirements, they pass rigorous test protocols, including 50,000 wear-free open/close operations. Available in 25-, 50- and 75-gallon sizes, DENIOS fire-rated safety cabinets are ideal for the storage of flammable and combustible liquids such as paint and coatings, solvents and more.

Robust construction incudes triple hinged self-sealing doors, and vent connections which automatically close in the event of a fire to protect stored flammables and minimize risk. Safety elements assembled outside the storage compartment for increased protection against corrosion. Integrated 3” air ducts are ready for connection to a technical exhaust system. Each cabinet includes three height adjustable tray shelves, a perforated insert, and a leak-tight welded bottom collection sump constructed of powder-coated sheet metal.

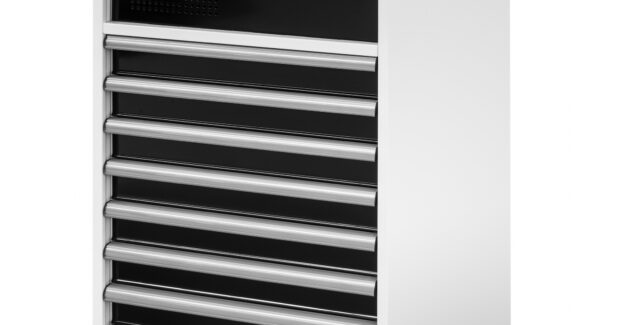

New V-Series 11-Drawer Mobile Workstation

CRAFTSMAN®, a Stanley Black & Decker (Towson, MD) brand has expanded its premium V-Series™ line to include metal tool storage. The V-Series metal storage includes a mobile workstation, rolling tool chests and cabinet combinations. The new V-Series 63” wide 11-Drawer Mobile Workstation is a workstation-storage system backed by a 10-year limited warranty. Featuring heavy-gauge steel and industrial quality casters, the mobile workstation has up to a 3,000-pound load rating. Additional features include:

- Full-extension soft-close, ball-bearing drawers capable of supporting 150 pounds-to-200 pounds.

- A full-grip tubular side handle for mobility.

- A six-outlet power strip with two USBs for convenient charging.

- A keyed internal tubular locking system to help protect tools when not in use.

- Pre-cut embossed drawer liners.

The Safer Way to Store Assembled CNC Cutting Tools

The Tool Caddy™ from Kaiser Manufacturing (Carol Stream, IL) is a compact storage solution for assembled CNC tooling. The narrow stainless-steel cart has up to 82 locking, horizontal pockets for all major spindle interfaces. The horizontal arrangement of the tool pockets greatly improves machinist safety. Traditional tool racks and carts keep tools in a vertical position with the cutter tip pointing up. This creates a risk of injury for operators when they need to reach over sharp edges to access other tools in the middle or back of the cart.

The Tool Caddy design makes it easy and convenient for the operator to grab each tool holder without any risk of cuts, and it uses only about four square feet of floor space. Each tool pocket is slightly angled to safely support the tool while allowing coolant to run off the tool tip and collect in the integrated drip pan. This further improves safety by keeping fluid spills off the shop floor.

Tool Caddy is practical and convenient for tool storage next to the machine, by the pre-setter, or for organizing special tool sets. It is available for CAT 40, CAT 50, HSK 63, HSK 100, BT and Capto tool holders.

Long Stock Storage Racks

In the dynamic world of metal fabrication, managing long stock materials like steel tubes, bar stock, angle iron, and aluminum extrusions can be a logistical challenge. These bulky materials demand careful handling and efficient storage solutions to optimize workflow and boost productivity. Enter LEAN Manufacturing Products’ (Waukesha, WI) innovative Long Stock Storage Systems — designed to streamline the inventory and accessibility of your long stock materials using a waffle-patterned cartridge with material dividers, all while minimizing your workspace footprint.

Fabricators across America are recognizing LEAN’s long stock storage as a game-changer for their shop floors. By adopting this cutting-edge solution, businesses are not only enhancing their operations but also experiencing significant growth in sales and revenue without needing to expand their current space. With seamless access to materials, operators can dedicate more time to value-added tasks, generate more orders, and ultimately achieve higher profits.

www.leanmanufacturingproducts.com

Tool Management System Includes Smart Vending Machines

To offer its customers an optimal tool data management and tool dispensing system, HAIMER (Villa Park, IL) cooperated with the TCM Group and its product lines WinTool and Toolbase. As a software solution for tool and data management, WinTool enables the management of tools, resources, machine programs, processes and master data. Toolbase is a smart tool dispensing system that includes individually configurable tool cabinets and software. It enables efficient access management via barcode, RFID or manual interaction. In the future, all HAIMER Microset presetting devices can be equipped with WinTool as a standard. HAIMER has prepared all parameters, step and DXF data in accordance with DIN 4000 and ISO 13399. The data is available to everyone for download on the HAIMER website and the Tooltracer data platform.

HAIMER tool holders will be lasered with a unique data matrix code in the future, which can also be used for tool management solutions. This means that a wide variety of information can be stored in a database for each tool holder and retrieved as needed — without the need for an RFID chip or a glued-on QR code. In addition, the digital data is already stored in the HAIMER WinTool system.

Data from other manufacturers can also be used in WinTool. For this purpose, the software offers a simple plug-in to Tooltracer, a cloud-based product that manages tool master data from different sources consistently and error-free.