New Holding System to Streamline Small Part Machining

Sandvik Coromant’s QS™ Micro delivers unprecedented precision in sliding head machines, which promises precision, security and repeatability, and maximized machine utilization.

Posted: November 11, 2024

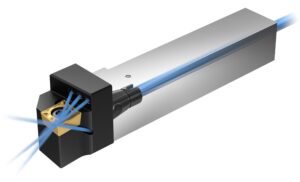

Sandvik Coromant, an industry-leading manufacturer of metal-cutting tools and solutions, has introduced the QS™ Micro — a new quick-change holding system developed specifically for sliding head machines. It promises exceptional precision, security and repeatability, and maximized machine utilization.

The QS Micro holding system is specifically designed for small part machining and sliding head machines. It covers the majority of industry segments, such as general engineering, automotive, aerospace and medical. With an extensive range of cutting heads and shank adaptors, the system offers a multitude of configurations and quick tool changes.

The assortment includes rectangular shaft adaptors in sizes 10 × 10 mm up to 20 × 20 mm, and equivalent inch sizes. It also features cutting heads for general turning, parting and grooving, and threading in the Sandvik Coromant families CoroTurn® 107, CoroCut® 2, CoroCut® XS and CoroThread® 266. The CoroTurn 107 and CoroCut XS families provide cutting heads designed for Y-axis machining, offering advantages such as higher stability and better chip evacuation.

“One of the main benefits of the QS Micro holding system is that it is possible to quickly change cutting heads with high precision, which reduces the machine’s downtime,” said Hampus Jemt, global product manager for small part machining and threading at Sandvik Coromant. “Another benefit is the modularity, which enables the fitting of different types of cutting heads in different adaptors, reducing the need for a large tool inventory.”

Other benefits include a rigid holding mechanism that minimizes vibrations, enabling unprecedented precision in sliding head machines without compromising process security. High indexing precision (+/- 3µm) also ensures supreme component quality, exceptional accuracy and repeatability across various operations.

Furthermore, efficient chip control is crucial in small part machining. All QS Micro shank adaptors provide through-coolant functionality, allowing easy coolant connection to the cutting heads, and the precision coolant is delivered directly to the insert. “Effective chip evacuation is critical. Chip smearing can significantly impact the intricacy of the machined parts. Fortunately, our through-coolant functionality results in exceptional chip control, extended tool life and increased productivity,” added Jemt.

Combining quick and easy tool changes with a high degree of modularity, QS Micro is ideal for small part machining operations where precision and security are of utmost importance.

About Sandvik Coromant

Together with our customers and partners, Sandvik Coromant leads the way toward a sustainable future, supplying tooling solutions to the world’s engineering industries. Over eight decades of hands-on experience have given us a wealth of knowledge in metal-cutting and machining. This expertise transforms every challenge into an opportunity for innovation, collaboration and progressive solutions. We aim to create positive change by promoting sustainability, efficiency and growth to shape a future where innovation thrives. Part of global industrial engineering group Sandvik, Sandvik Coromant is shaping the future together.