Machining Synergy: How Tool Holder and Tooling Choices Affect Your Results

Modular tooling assemblies can be a major advantage for shops that need flexibility or specialized tooling.

Posted: November 16, 2024

You’ve heard it before: Machine, spindle interface, tool holder and tooling choices must all come together in synergy to get the most out of your production. But with nearly endless possible combinations—and unique machining challenges to consider—how can you ensure peak performance? In this article, we’ll explore key considerations and examples of how these match-ups can go very right—or very wrong.

Start with the Machine and Spindle

For seasoned pros, it comes as no surprise that everything starts with the machine choice. Application-specific tool holders and tooling combinations work best (or exclusively) on machines in which the spindle interface, RPM, horsepower and torque specs align. For job shops that have to meet a variety of cutting needs, this reality comes with tradeoffs.

For example, a shop might be considering a 50-taper machine tool with a CAT interface to cover the heavy-machining side of its business—where torque and horsepower are of utmost importance. This choice, however, could come at the expense of the shop’s high-speed machining needs. At this point, the shop must decide where the majority of their work lies. If the answer is on the high-speed side, they may choose a higher-RPM machine with an HSK interface. To compensate for the loss of torque and horsepower needed for their heavy-machining applications, they might leverage a larger HSK 100 tool holder or plan for high-speed machining strategies such as trochoidal milling. They’ll need to analyze the horsepower and torque curve at the desired RPM and adjust the cutting parameters accordingly.

Even the most advanced machines can’t compensate for poor-quality tools. A machine’s performance is directly influenced by the tools it uses, so it’s essential that tool holders and tooling are precisely aligned with the required quality and application demands to achieve reliable results.

Understand the Mechanics of Your Tool Holder

Speaking of high speed vs. high torque, it’s crucial to understand the dynamics of different tool holder systems to understand which will be right for your application.

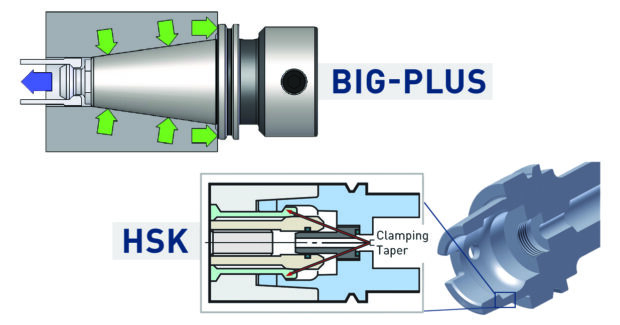

Back to the CAT vs. HSK example: Traditional BT or CAT tool holders are single-contact—meaning the tool holder taper only makes contact with the spindle. BIG-PLUS BT and CAT tool holders, however, feature a second point of contact. HSK systems are also dual-contact, but the mechanism through which they achieve it is different from traditional steep-taper tool holders. Both systems leverage natural elastic deformation during spindle rotation, but in unique ways:

- BIG-PLUS tool holders use the elastic deformation of the spindle to create the second point of contact (in which the spindle expands until the tool holder flange makes contact with the spindle face).

- An HSK tool holder system features drawbar fingers inside the hollow shank that push out on the tool holder as speed increases. In this case, even with elastic deformation of the spindle at higher speeds, the clamping remains constant.

Because of these different clamping mechanics, HSK will work better with smaller tools at higher speeds (because the speed ensures strong clamping force). BIG-PLUS, on the other hand, offers more flexibility for tool choices and greater stability for heavy machining.

Think about tooling tradeoffs

Just as machine choices come with tradeoffs, so do your choices of tooling and tool holder combinations. At BIG DAISHOWA, we pay close attention to these tradeoffs, and are dedicated to helping clients navigate them to determine the best tooling for their application. For example, this chart provides a good high-level breakdown of the pros and cons of each type of tool holder so machinists can make the right choice. Here are a few more specific examples:

- Shrink-fit tool holders are considered high accuracy. Most customers say that the MEGA NEW BABY collet system from BIG DAISHOWA offers greater flexibility with the same accuracy.

- End mill holders—largely considered an outdated tool holding technology—offer 100% clamping security but the worst runout of any tool holder option.

- ER chucks, on the other hand, offer the best accuracy—but only if the collet quality is up to par.

- HSK and shrink fit holders allow for good length-to-diameter ratios. But they may transmit too much vibration to the spindle. In the case of tight tolerances, hydraulic holders might be a better option because they dampen vibration that could otherwise cause bores that aren’t up to spec, resulting in scrapped parts.

As you can see, the considerations can be daunting. That’s why it’s crucial to work with an expert tooling partner who can shine a light on the pros and pitfalls of each tool holder-tooling combo.

Use Modular Assemblies with Care

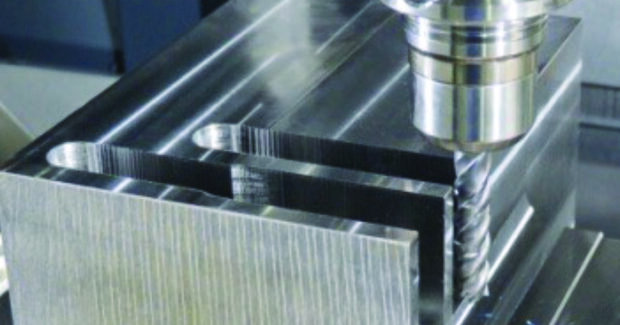

There are many cases in which a shop might opt for a modular tool holder/tooling assembly (which could include shanks, reductions, extensions, solid bars, damping bars, collet adapters and coolant inducers). In fact, modular tooling assemblies can be a major advantage for shops that need flexibility or specialized tooling. Keep in mind with every extension and connection you’ll have a marginal increase in runout and need to adjust cutting speeds accordingly. Consider modular tooling for:

- Job shops that handle a large number of applications can save money and increase flexibility with modular assemblies.

- Large and complex parts may require a specialized modular assembly to achieve the cut.

- Shops can save time with modular tooling because they don’t have to order pre-built custom tool assemblies.

- Deep or specialized boring and tapping operations may require modular extensions to get the job done.

The general rule of thumb is limiting modular boring assemblies to 4x diameter or three to four connections. But, as always, there are exceptions. For some very complex, large aerospace parts, for example, we’ve seen modular assemblies as long as 60 inches. But (and this is a big but), it’s crucial to tackle these under the guidance of a tooling expert. Longer tool assemblies with multiple connections come with runout and spindle droop issues, so you’ll need to adjust cutting speeds and feeds to ensure adequate accuracy and safety.

BIG DAISHOWA experts have worked with major aerospace OEMs on modular assemblies that ensure high-stakes parts are produced safely and to spec. With any modular assembly, make sure you’re consulting with a tooling partner you trust.

Suppliers Matter

And speaking of suppliers you trust, don’t spend on the machine and neglect tooling considerations.

Every component of the tooling assembly matters, and one subpar element can have big repercussions. Take BIG DAISHOWA collet chucks for instance: The chuck, collet and the nut are all manufactured to tight tolerances to ensure the highest precision. Replace one component with something from another manufacturer and you could be cutting machining accuracy by a third.

Another pitfall is assuming that the type of tool holder is all that matters. For example, some people think any ER collet will provide ideal finishes. But one nearly invisible burr in a low-quality collet could cause runout you didn’t see coming. Ensuring a burr-free collet requires additional machining, which incurs extra costs, but the price is worth it for the precision and reliability achieved.

Finally, any time you’re experimenting with new or specialized tooling assemblies, it pays to go premium. The added quality assurance and application support ensure a smoother, more fool-proof implementation and better results.