Introducing Automatic Tool Change for Turning Centers

Sandvik Coromant introduces automatic tool change for improved machine utilization and productivity. This unique solution enables unmanned production, free from manual handling, for improved machine utilization and increased output.

Posted: November 18, 2024

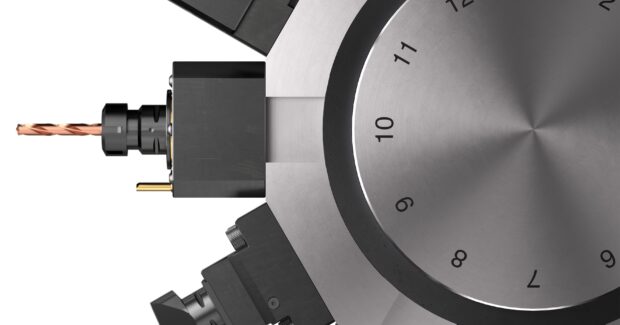

Sandvik Coromant, a manufacturer of premium metal-cutting tools and solutions, is introducing automatic tool change (ATC) for machine-adapted clamping units (MACU) in turning centers.

In complex part production, the time-consuming process of manual tool changes often results in low utilization of turning centers. However, a new automatic tool change solution for machine-adapted clamping units addresses this issue by enabling full automation in turning centers.

ATC for MACU enables full automation for turning centers and eliminates the need for manual handling. The result is higher machine utilization and increased productivity. Furthermore, complex part production becomes more efficient with an ATC-enabled turning center, streamlining the manufacturing process. The result is a quick return on investment that will lower the cost per part.

“This solution is a true game-changer, enabling fully unmanned operations in turning centers where robots can handle all tasks typically performed by human operators,” says Bo Hammarberg, global product manager at Sandvik Coromant. “Previously, robotic tool changes were slow and imprecise, often resulting in broken tools due to incorrect torque values, which is costly over time. Our automatic tool change technology for turning centers now offers unprecedented flexibility and control over tool holder setups.”

Interest in automated solutions has been growing steadily over the past decade, and Sandvik Coromant has been at the forefront of its development. “In 2010, we identified a growing trend: customers were increasingly looking to invest in automation for turning centers. The idea of a fully automated lathe couldn’t be ignored,” Hammarberg explains. “In 2012, we developed and showcased a small robotic cell, which sparked significant interest from customers. We’ve continued to develop the solution since and are now at the point where we can make this solution available to existing and future customers.”

ATC also offers significant sustainability benefits. Key advantages are reduced energy consumption, resource efficiency, waste reduction and improved overall equipment efficiency (OEE). Efficiently utilized machines operating at optimal levels will minimize idle time and energy waste, enable more output with fewer resources and lead to fewer breakdowns and reduced downtime.

The technology is applicable in turning centers and multi-task machines. A requirement for applying ATC is a MACU with a Coromant Capto® interface. For turning centers, a specific ATC-enabled MACU turret is needed, while in multi-task machines with a lower turret, ATC is possible if the turret is ATC-prepared.

Visit the Sandvik Coromant website to learn more about automated tool change and other turning solutions.

WATCH VIDEO “Automatic tool change in turning centers”

About Sandvik Coromant

Together with our customers and partners, Sandvik Coromant leads the way toward a sustainable future, supplying tooling solutions to the world’s engineering industries. Over eight decades of hands-on experience have given us a wealth of knowledge in metal-cutting and machining. This expertise transforms every challenge into an opportunity for innovation, collaboration and progressive solutions. We aim to create positive change by promoting sustainability, efficiency and growth to shape a future where innovation thrives. Part of global industrial engineering group Sandvik, Sandvik Coromant is shaping the future together.