Harness the Power of Welding Automation and the IIoT

How IIoT can improve efficiency, quality and safety.

Posted: November 16, 2024

Everyone knows the adage “knowledge is power,” but it rings even truer in welding. There are a lot of variables to consider that help ensure a clean, high-quality weld. Historically, it has taken years of doing and fine tuning to acquire such knowledge and skill. The integration of the internet and its subsequent digitalization has been a welcome benefit to the industry to take some of the guesswork out of welding and run a more efficient operation.

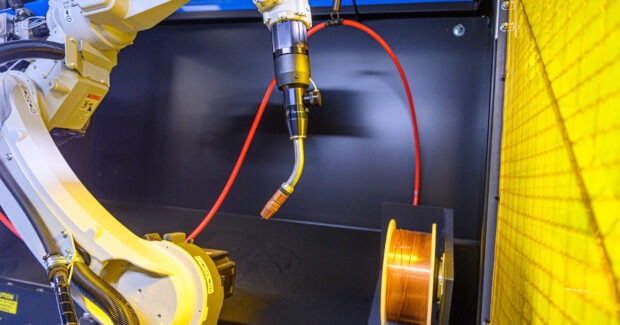

The Industrial Internet of Things (IIoT) has improved efficiency, quality and safety through its internet-connected sensors, devices and data analytics. It gives operations the precise information they need to make proactive and informed decisions. Not only that, IIoT can be paired with welding automation systems, making it possible to take advantage of automation’s precision and efficiency and further elevate it with connectivity and data-driven insights for the benefits of the operation.

Set the Stage with Welding Automation

Like many things, data is an asset that can be positively wielded for making improvements and informing decisions — even in a manufacturing setting. When welding automation systems are connected through the IIoT, communication and data sharing is possible across those centralized systems, creating real-time information and coordination across the entire operation.

Even apart from IIoT, welding automation contributes significant advantages, including:

- Enhanced productivity: Automation is ideal for tasks that require precision and consistency, making it perfect for high-volume part runs. Robots perform repetitive tasks at a consistent pace with minimal human intervention, mitigating the risk of errors and improving part throughput.

- 24/7 availability: Integrating automation alleviates the stress of not having enough skilled welding operators to produce the number of parts needed. For proper execution, the right infrastructure needs to be in place, including the appropriate electrical and air drop downs, the right tooling, the required gating and knowledgeable technicians and programmers who can properly set up and maintain the robots.

- Optimized safety: Robots undertake the repetitious motions of welding that can negatively impact welding operators. Robots don’t have to contend with ergonomic issues like humans do, which eliminates the risk of injured operators. Additionally, robots don’t have to worry about the negative impacts of weld fume; however, fume mitigation (e.g., a hood or extraction system) is still required for compliance and the safety of the operation at large.

While those benefits are impactful in and of themselves, using IIoT to layer digitalization into an operation takes welding manufacturing to a whole new level.

Amplify learnings with the IIoT

While automation itself advances a welding operation’s efficiency and productivity, IIoT can augment that even more. In fact, smarter, more responsive welding comes from the ability to make data-driven decisions stemming from the outputs welding automation and the IIoT provide. The large amounts of data allow for improved welding processes and optimized resources, which benefits welding in the following ways:

- Real-time monitoring: Sensors and programs attached to the welding robots can continuously monitor welding parameters, ensuring that the performance stays within the specified programming limits. Any deviations can trigger alerts so that engineers or technicians can address them immediately. Additionally, this information is accessible both onsite and remotely, providing greater flexibility for operators who need to quickly diagnose and fix the issues.

- Predictive maintenance: Digitalizing a shop makes it possible to pinpoint issues in a particular line or weld station, providing insight into when preventive maintenance should be conducted. Some systems can even alert an operator of an impending issue before the critical tipping point to avoid a catastrophic failure.

For example, IIoT can monitor critical benchmarks — such as a robotic arm’s temperature — that would signal maintenance needs. Temperature is a big indicator of what’s happening during the welding process and a bellweather for potential issues. A welding torch has a specific operating window where it works best, and if it exceeds that limit, there’s a substantially greater risk of failure or malfunction. Continuously monitoring the operating temperature of the equipment allows for quick, precise action before something bad happens and causes unexpected downtime.

Also worth mentioning is the benefit of having all of this historical data, which provide a bigger-picture view and give teams the opportunity to plan for expected downtime. The result is the ability to transform windows of inactivity into windows for maintenance without negatively impacting productivity. - Get the most use out of equipment: Data can also help save an operation money on consumables and equipment. Thanks to insights stemming from the predictive maintenance, operators will only need to replace what they’re being told needs to be replaced — versus assuming something needs to be replaced. Replacing things prematurely amounts to unnecessary spending, and IIoT data will more clearly indicate what needs to be replaced and when, preventing waste and ensuring the most life is gotten from the products.

- Reduced scrap and rework: Increased monitoring leads to improved quality control. Catching issues before they happen results in less scrap and rework and creates significant cost savings across materials and labor.

- Continuous improvement: Because the IIoT collects vast data from automated welding processes, it gives operations the information needed to better identify trends, optimize welding parameters and improve overall process efficiency on an ongoing basis. Instead of being caught flat-footed, the data provide a clearer vision of what’s happening and the opportunity to plot a roadmap for what’s possible.

Pairing welding automation with the IIoT is leading to more efficient and responsive processes across the shop floor, fueling greater quality, productivity and efficiency. These are the attributes all operations strive for — and that digitalization can help make a reality. By leveraging the power of IIoT, new levels of performance can become unlocked, setting the stage for continuous innovation in manufacturing.