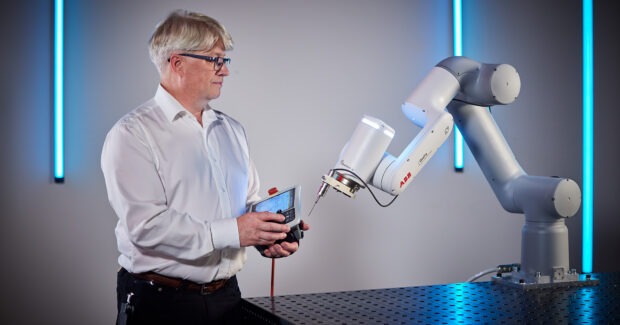

Groundbreaking Ultra Accuracy for GoFa Cobots

ABB’s Ultra Accuracy feature increases accuracy by 10 times in GoFa cobot family vs. other cobots on the market.

Posted: November 7, 2024

ABB Robotics recently launched Ultra Accuracy, a new industry-leading feature for its GoFa cobot family that delivers the highest level of precision available in cobots, enabling over 10 times greater path accuracy vs. other cobots on the market.

“As industries look to automation to enhance product quality and achieve tighter tolerances – continuously decreasing the maximum allowable deviation from the standard in quality control – there is a growing need for robots that can perform tasks with exceptional precision,” said Andrea Cassoni, Global Head of Collaborative Robots for ABB Robotics. “By combining ultra-accurate path performance with GoFa’s inherent simplicity, safety, and flexibility, ABB’s new Ultra Accuracy feature opens a wide range of possibilities for the use of cobots in businesses including electronics, automotive, aerospace, and metal fabrication.”

With its superior performance, Ultra Accuracy meets the demands of applications where exact positioning is crucial for maintaining product quality and operational efficiency. Applications include gluing and sealing in consumer electronics production, laser welding of car parts, composite material layers in aerospace manufacturing, and precision laser cutting in metals fabrication processes. It can also be used for accurate positioning of additive layers in building prototypes in 3D printing, and for performing precision quality checking in metrology applications.

Additional benefits include the combination of precision with speed and a full range of motion. Unlike conventional 2D gantry systems traditionally used in electronics manufacturing, GoFa cobots offer full 6D motion across their entire workspace upon delivery, without requiring additional calibration work, providing the flexibility and mobility to handle a broader range of tasks.

GoFa’s compact and portable design ensures that it can be easily integrated into existing production lines without the need for expensive customization, offering a distinct advantage over gantry-based systems. GoFa with the Ultra Accuracy feature can be introduced into production with minimal installation and deployment time, as the calibration is done in the factory prior to delivery.

The powerful combination of Ultra Accuracy and RobotStudio® enables the programming of applications offline, with a 99% match between the simulation and reality, eliminating the need for touch-ups and guaranteeing precise and efficient implementation. The Ultra Accuracy feature is available for new GoFa cobots and as a retrofit option for existing GoFa cobots.

For more information about GoFa collaborative robots and the new Ultra Accuracy feature PLEASE visit https://new.abb.com/products/robotics/robots/collaborative-robots/crb-15000