Faster, More Consistent Consumables Ensure High-performance Applications

Advancements in weld quality and ease of use improve the productivity of wire feeders, filler metals and electrodes.

Posted: November 16, 2024

Digital wire feeders and smart systems make welding easier and more consistent, while advanced filler metals and electrodes offer better performance in demanding conditions. These technologies drive advancements in precision while reducing costs across a range of industries.

Shielding Gas and Flux Cored Wire Combine to Provide Consistent Welding Results

The shielding gas used when welding has great impact on final product quality. Inconsistencies in the shielding gas can lead to issues like spatter, oxidation and weld defects. Additionally, selecting the right shielding gas to use can be time-consuming and confusing with complex offers that include too many options.

The ARCAL™ line of shielding gases from Airgas (Radnor, PA), an Air Liquide company, simplifies gas selection and provides users with the high-quality gas needed to produce better welds. The ARCAL line includes five ready-to-weld pure argon and argon gas mixtures: Argon (99.998%), 2% CO2 balance argon, 8% CO2 balance argon, 18% CO2 balance argon and 25% CO2 balance argon.

ARCAL gas cylinders from Airgas are also equipped with SMARTOP™ or EXELTOP™ cylinder valve technology with at-a-glance pressure gauges, quick on/off levers and a permanent safety top that protects the valve at all times and lowers the risk for injuries. ARCAL shielding gases also come in various other supply modes to accommodate a customer’s needs.

Customers can also get a winning combination for their welds by combining ARCAL Flux premium shielding gas with RADNOR™ Flux Cored Wire to get consistent stainless steel welding results every time. Available in-store and online, this wire is level-layer wound and vacuum-sealed for assured consistency when welding.

HyperFill RA is the Latest Evolution in Twin-Wire Welding

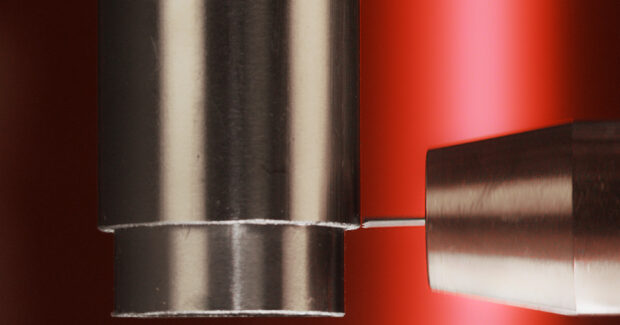

Lincoln Electric® (Cleveland, OH) announces the latest evolution of the HyperFill® Twin-Wire Welding Solution with expansion of the new HyperFill® RA for increased travel speeds, improved cycle times and added throughput for automated welding.

HyperFill technology combined with RapidArc® waveform allows for tighter and more focused arcs with increased travel speeds of up to 58% compared to traditional CV or pulse single wire processes in automotive and heavy fabrication industries. HyperFill technology requires only a single power source, feeder, gun liner, contact tip, and arc, making it easy to use and providing maximum ROI.

“HyperFill RA gives the appeal of running like a single wire GMAW operation but with the travel speed of running twin wires,” said Kevin Fleming, global industry segments – automotive manager, Lincoln Electric. “In the world of automation, our customers are looking for ways to increase travel speed without adding the complexity of tandem MIG or additional equipment.”

HyperFill RA benefits include:

- Increased travel speeds up to 58%.

- Ideal for smaller fillet and lap weld sizes (6 mm and less).

- Reduced capital equipment cost.

- Deliver improved cycle times and throughput in automated welding.

“On the heavy fabrication side, customers who had weld size limitations with standard HyperFill can now expand the work envelope with HyperFill RA to weld smaller weld sizes, a true game changer for increased productivity,” stated Lou Mendoza, global segment director – heavy fabrication, Lincoln Electric. “Expanding equipment/solutions capabilities is a key advantage.”

Overall, HyperFill RA technology offers significant advantages for welding in the automotive and heavy fabrication industries. While its ease of use and reduced equipment costs make it an attractive option for businesses looking to improve their welding processes, operators can increase their productivity and maximize ROI with faster and more precise welding.

Top Quality Thanks to Intelligent Robot Assistance Systems

WireSense, TouchSense, SeamTracking, and TeachMode are patented assistance systems for robotic welding designed by Fronius (Portage, IN) to improve weld quality and increase efficiency in industrial manufacturing. The welding wire acts as a precise sensor for the robot and simplifies welding path programming or detects deviations in the component position as well as air gaps over the course of the seam. Using this data, the robot can then correct the weld path — adjusting it precisely based on the identified position points — to save material, time, and cost, as rework and component rejects are no longer an issue.

For example, when it comes to detecting the edge position and air gap height, “Our revolutionary WireSense technology uses the scanning function of the reversing CMT wire movement to determine the exact position of the component and edge as well as air gap heights,” said Philipp Schlor, strategic product manager, industrial welding solutions at Fronius International. “Steel, stainless steel, and aluminum sheets from 0.5-to-20 millimeters thick can be scanned quickly and precisely.”

Every raising and lowering operation on the component can be recorded extremely accurately relative to a reference point specified at the start of the scanning process. In just seconds the robot has compared the taught positions with those measured, or in other words it has checked the stored values against the actual position data. If it detects any differences, the course of the seam is adjusted accordingly in the robot’s coordinate system and the weld is produced in the right place.

“WireSense opens up a multitude of possibilities for robot integrators to identify high-quality solutions for challenging welding tasks,” Schlor said. “The edge being welded doesn’t necessarily have to be detected. Any fixed reference edge on the component, such as the component edge or a notch, can serve as the starting point from which welding is to take place at a certain distance. This enables even difficult-to-detect parts, like a rounded sheet, to be welded at the desired position.”

Expansion to Flux-Cored Wire Line

Weldcote (Kings Mountain, NC), a division of Zika Group, expands its product line to include Mighty Arc flux gas shielded and mild steel flux-cored wire line. Weldcote’s product line consists of abrasives, a wide range of production alloys for MIG, TIG, electrodes, brazing, welding machines and welding accessories, including lenses, helmets, chemical aids and gloves.

Designed for single, multiple pass and all-position welding, the Mighty Arc flux gas shielded and mild steel flux-cored wire line includes carbon baked steel, carbon steel and low alloy high-strength wires. The flux-cored wire provides a convenient, more efficient welding process that replaces standard stick electrodes.

The Mighty Arc flux-cored line features wire that has lower spatter, lower fume emissions, excellent mechanical properties, a smooth arc and can be used for a variety of applications.

“Our Mighty Arc flux-cored wire is convenient and efficient because it allows for continuous use with no interruptions,” said Joe O’Mera, CEO of Weldcote. “Our flux-cored wires can be used on a variety of applications including structures like buildings, ships, bridges, machinery, vehicles, high-pressure vessels and in oil-refining industries.”