A FABTECH First: Dual-axis Cobot Welding with Coordinated Motion

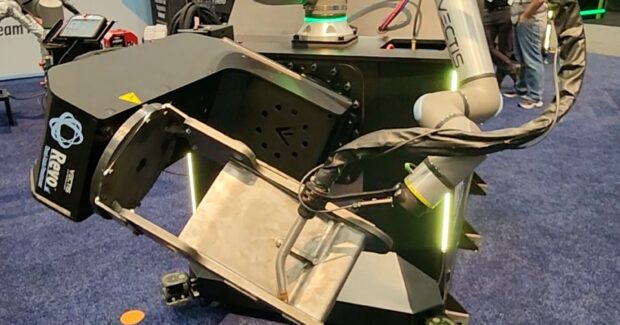

At FABTECH, Vectis Automation launched the Revo Dual Axis system, a multi-axis positioning method that tackles complex multi-faceted parts and excels in situations where the fabricator needs to get parts in position relative to gravity.

Posted: November 11, 2024

At FABTECH 2024 in Orlando, Fla., the event was home to a FABTECH first, showcasing Universal Robots’ (UR) dual-axis cobot welding with coordinated motion through the cobot’s own controller.

The new capabilities are possible through UR’s new MotionPlus package that enables UR’s welding partners to add dual-axis coordinated motion capabilities to their own solutions. “To our knowledge, this is the first time multi-axis cobot welding with coordinated motion is showcased in North America,” said Will Healy III, global industry leader of welding at Universal Robots.

Vectis Automation is one of the first UR partners to leverage MotionPlus, launching the Revo Dual Axis system at FABTECH 2024. The new multi-axis positioning method can tackle more complex multi-faceted parts and excel in situations where the fabricator needs to get parts in position relative to gravity.

Vectis also showcased QuickTeach and AI Path Optimization; QuickTeach allows the cobot champion to teach points and optimize paths right at the torch. AI Path Optimization applies user-defined work angles, push/pull angles, and smoothed corner transitions to the weld path — ensuring the weld is always created according to the procedure specifications.