FABTECH 2024 METALFORM

The latest metalforming technology will be on display at Fabtech.

Posted: October 2, 2024

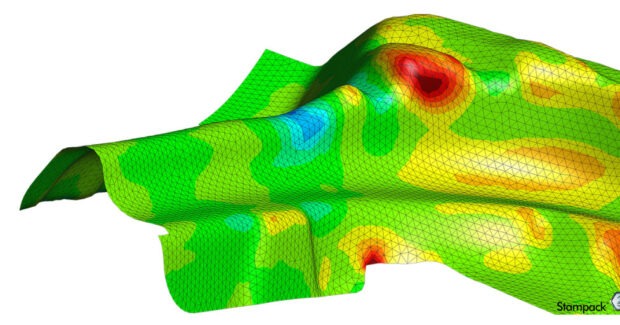

Affordable Simulation Software for All-size Tool and Engineering Shops

Accurate Die Design Software, Inc. (West Allis, WI), located in Booth S-31062, will demonstrate and highlight Stampack Forming Simulation software. The software is easy to use, and the user does not need finite element or material science experience. Stampack is also affordable for all-size tool and engineering shops and will accurately simulate everything from large automotive line dies, transfer dies, and progressive dies, to small progressive dies making tiny electrical and medical parts. Due to shell and solid technology included in one software, Stampack will provide both fast and high-precision calculations for final validation. Both thin and thick sheets can be simulated precisely.

Simulation accuracy in manufacturing is crucial for predicting real-world outcomes and avoiding costly errors. For example, in the case of high-strength steel forming, a shell simulation might show safe results, but a solid simulation can reveal potential cracks, ensuring better safety and reliability. Accurate simulations help validate methods and materials, ultimately leading to more efficient and successful manufacturing processes.

Stampack detects cracks, surface defects, and wrinkles in the metal forming processes for stamping, deep drawing, ironing, coining, hydroforming, stretch forming, and incremental sheet forming.

Multidirectional Sideloader Industry’s First Aisle Entry Assistant

The first sensory aisle entry assistant for multidirectional sideloaders is available from HUBTEX North America (Fredericksburg, VA). The company will be in Booth S-31003. Using 2D lidar sensors, it guides sideloaders precisely into narrow aisles, reducing collision risks and damage, and is compatible with all PhoeniX models.

Increase storage capacity in confined spaces: By using multidirectional sideloaders in narrow-aisle warehouses, companies benefit from maximizing their storage capacity. Consequently, operators face challenges with this warehouse layout. One is entering the narrow aisle with pinpoint accuracy. HUBTEX has developed the industry’s first sensory aisle entry assistant, enabling equipment handling long goods to enter aisles without collision. All PhoeniX models can be equipped with the new assistance system. The principal working environment of multidirectional sideloaders is narrow aisles. Guide rollers with corresponding rails mounted to the rack are the dominant method to keep the forklifts on track. Just four inches is the distance between the sideloader and the rack. Facilitating the approach into the aisle is usually a funnel whose size is determined by the length of the transported goods. Long loads lead to long funnels resulting in wider transfer aisles. Entering a narrow aisle without assistance always poses a challenge for operators. If there is only a small deviation from the right path, the sideloader, its load, the rack or the rails could be damaged. Overhanging loads and reverse entry don’t help the situation either. The HUBTEX system processes the raw data of a 2D lidar sensor. The laser scanner determines the relative distance to the entry funnel and orients the vehicle to the center of the aisle. “Based on this information, the assistance system aligns the truck centrally in front of the aisle and parallel to its course,” explained Michael Röbig, head of product management at HUBTEX. “The truck can therefore enter the aisle without colliding. This allows the driver to concentrate on monitoring the vehicle’s surroundings and set a speed appropriate to the situation.” There are two versions available: a stand-alone system and an integration into the pedestrian safety system.

Software for any Tool Design Including Dies, Gauges, Fixtures and More

Accurate Die Design Software, Inc. (West Allis, WI), located in Booth S-31062 will demonstrate and showcase LogoPress Die Design software. LogoPress can be used for any tool design including dies, gauges, fixtures, and special machines. The software provides a mature and systematic workflow for tool design, adding all the necessary tools and options that die designers need to help automate and eliminate mistakes from the die design, debug, and build processes. All types of die design benefit from LogoPress including progressive dies, fineblank dies, transfer dies, hand feed line dies, slide tooling, etc.

Some important features of the design software include:

- An intelligent Catalog Component Library with automatic hole creation, automatic patterning, and automatic creation/mating of components. Includes more than 100 components provided by nearly 50 manufacturers in an even combination of inch and metric.

- DIE DEBUGGER™ feature which quickly simulates all the motions of the die or tool — including cams, transfer system, etc. Includes First Hit Optimizer, Slug Clearance Detection, and Dynamic Interference Detection (find interference while the tool is cycling as if it were in the press, with the strip lifting and advancing).

- StripLayout is invaluable to die designers for creating fast strip layouts and estimating. It includes LogoPress Flatten, Nest, Round Draw Part, and tools for cutting and forming punch creation. Quoting data includes material usage, cutting force, forming force, total punch perimeter (for WEDM), etc.

- LogoPress Flatten works with dumb solids that can be imported from any CAD system into SOLIDWORKS. It can unbend and flatten even very “dirty parts” in a matter of seconds. Includes FEA flat blank prediction, unbending, overbending, partial unbending (moved center and fixed center) and extrusions.

- An intuitive interface to nest parts in a strip or a plate.

Logopress ProSim is an add-on that performs accurate forming-process simulations using incremental simulation technology powered by the industry-proven AutoForm solver.

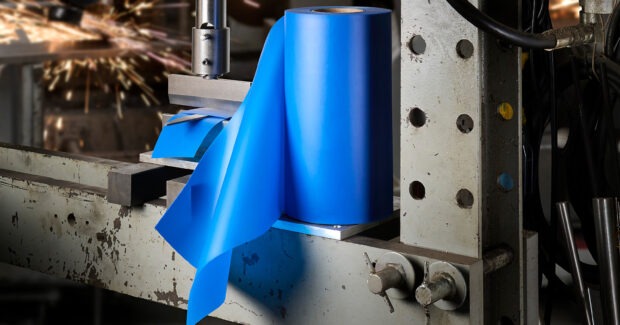

Press Brake Protection Film Eliminates the Need for Secondary Processes

MarFree!™ urethane press brake film from Pepin Manufacturing Inc. (Lake City, MN) saves you money by protecting your finished parts while minimizing die wear. The company will be in Booth S-34088.

In many cases, finished parts are used in a setting where cosmetics and appearance are important. Using MarFree! press brake protection film eliminates the need for secondary polishing and refinishing, as well as having to scrap expensive blanks. When you use MarFree, your business can reduce manufacturing costs by eliminating a manufacturing step, while increasing the life of the die.

- Prevents Marking on metal and various materials.

- Durable, competitively priced, and long-lasting.

- Available in various widths and thicknesses and durometers.

Products Enable Work to Get Done, from Forming Lubricants and More

Quaker Houghton (Conshohocken, PA) is the leader in industrial process fluids. Our innovative, advanced technologies enable customers to stay ahead in a changing world. We are proud to support global manufacturing across industries with the products that enable them to get work done, from forming lubricants and surface treatments to fire-resistant hydraulic fluids and customized greases.

Quaker Houghton is leading the way in digitalizing fluid management with QH FLUID INTELLIGENCE™ solution, a complete solution for measuring, controlling and optimizing industrial process fluids. If it’s made of metal, if it’s rolled, cut, ground, drawn or cast, Quaker Houghton is there, optimizing processes, reducing total cost of ownership, advancing safety and sustainability and driving progress. Together.

https://home.quakerhoughton.com

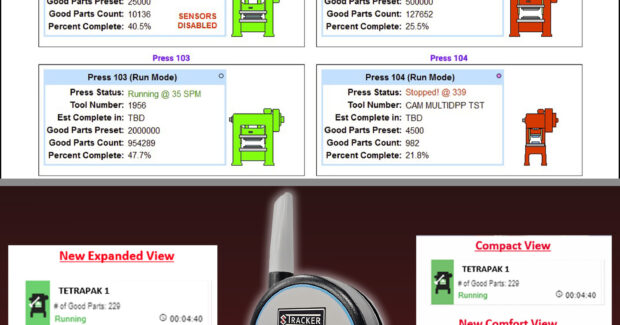

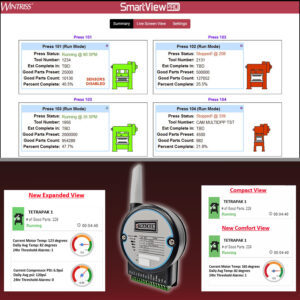

Debut of New Interface for Press Automation Controller

Wintriss Controls Group (Acton, MA) will demonstrate a new, advanced interface in its SmartPACuaker PRO Press Automation Controller and an economical ShopFloor Data Tracking Solution at Booth S-29074. For a connection to a smarter factory, including when remote monitoring is required, the latest functionality in SmartPAC PRO and ShopFloorConnect (SFC) gives fabricators and metal formers efficient and easy-to-use tools to control, automate and track their vital operations.

Wintriss will be introducing the new SmartView PRO Network Interface for its industry leading SmartPAC PRO Press Automation Controller. The new interface allows any PC or mobile device on a network to access and download information from networked SmartPAC PRO controls.

The new interface displays the current job status, press tonnage, percent of job complete, and estimated time until job completion. Users can also view the SmartPAC PRO’s error and event logs, send an on-screen text message to the press operator, and download the installed option list, tool list, and individual tool programs.

Wintriss will also demonstrate its new, compact SFC ShopFloor Tracker hardware device, an economical way for its ShopFloorConnect Software to automatically collect production data from virtually any machine. The SFC Tracker is a wireless machine monitor that can be installed on any machine or production line to track machine parameters such as run time, idle time, production counts, production rate, uptime efficiency, temperature, pressure, humidity, and more without requiring any operator input. The most outstanding trait of the SFC Tracker is its versatility, featuring four inputs that can be configured to accept input from a variety of digital or analog signals.

In addition to Wintriss’ booth presence at the show, industry die protection expert Jim Finnerty of Wintriss will be presenting “Sensors for Die Protection” in Room S06 from 8:30 a.m.-to-10 a.m., on October 16th. He created the Wintriss Die Protection Clinic, industry’s premier source for die protection and in-die sensing information and training, which he has led for over 25 years.