Is Your Workholding Scary?

But fear not; we’re here to shine a light on those dark corners and show you that workholding doesn’t have to be a nightmare.

Posted: October 31, 2024

As the autumn leaves fall and jack-o’-lanterns light up porches, a different kind of fright might lurk in your machine shop. No, it’s not a ghost or a goblin – it’s your workholding setup! But fear not; we’re here to shine a light on those dark corners and show you that workholding doesn’t have to be a nightmare.

Your fears are paralyzing production.

Many machinists and operators approach their workholding setup with the same trepidation as entering a haunted house. Will the part fly out like a bat from a belfry? Will changeover times drain productivity like a vampire drains blood? These fears can paralyze production and turn your shop floor into a scene from a horror movie.

The specter of inconsistent clamping force leading to part movement looms large in many shops. Complex setups that waste valuable production time feel like a curse on efficiency. The inflexibility when dealing with various part geometries is a straitjacket. And perhaps most terrifying of all, the ever-present danger of tool crashes due to improper workholding can send chills down any machinist’s spine.

But what if we told you these fears are just illusions, like the smoke and mirrors in a haunted house?

Myth: Powerful clamping always risks part deformation. Reality: Modern workholding solutions offer precise, adjustable clamping forces.

Myth: Versatile workholding is always complex and time-consuming. Reality: Advanced systems can offer both flexibility and quick changeovers.

Myth: High-precision workholding is only for large-scale operations. Reality: Innovative solutions are available for shops of all sizes.

Forget outdated fixtures that haunt your shop.

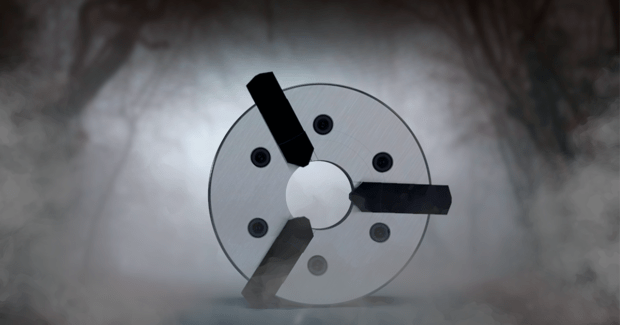

Implementing modern workholding solutions is easy, and the HAINBUCH SYSTEM is here to exorcise your workholding demons.

The HAINBUCH SYSTEM transforms your machining process from a horror show of long setups and inflexibility into a well-choreographed performance of efficiency and precision. This system offers a modular approach, as versatile as a shapeshifter.

At its core, the HAINBUCH SYSTEM features quick-change capabilities that slash changeover times. The system’s adaptability allows for seamless transitions between O.D., I.D. clamping 2- and 3-jaw clamping, between centers, and more – much like a werewolf effortlessly shifting forms under the full moon. Whether you need to switch from a chuck to a mandrel or accommodate a wide range of part geometries, the HAINBUCH SYSTEM has you covered.

Precision is the name of the game. The HAINBUCH SYSTEM delivers scary good accuracy. It ensures your parts are held securely without any distortion. This level of precision leads to improved part quality. The beauty of this lies in its simplicity. You don’t need to be a wizard to operate it. The intuitive design makes operation straightforward for all skill levels.

But the real treat is ROI. The HAINBUCH SYSTEM pays for itself. You will see frighteningly fast returns by dramatically reducing setup times, increasing machine utilization, and improving part quality.

Face your fears.

So this Halloween, while others fight off ghosts and goblins, you can face your workholding challenges head-on. With HAINBUCH, you’ll find that the only thing scary about your workholding is how frighteningly efficient it can be!

Don’t let outdated workholding practices haunt you. Treat yourself and your shop to the HAINBUCH difference – with the right workholding solution, every day can feel like Halloween, full of treats and no tricks!