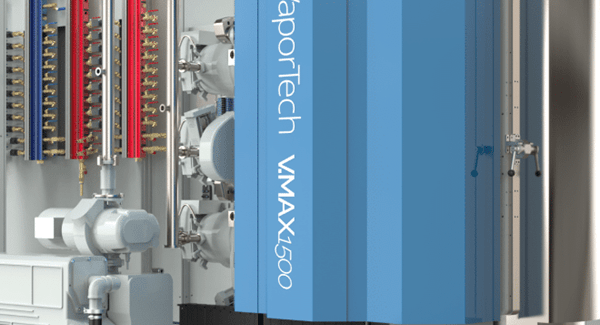

Vapor Technologies Announces new Industrial Flexible Coating System

The new V.MAX1500 PVD and DLC flexible coating system offers new capabilities, including up to six wall-mounted cathodic arc and/or magnetron sputtering sources.

Posted: September 26, 2024

Vapor Technologies (VaporTech®), a leading provider of physical vapor deposition (PVD) coating solutions, announces the new V.MAX1500 PVD and DLC flexible coating system. This machine offers new capabilities, including up to six wall-mounted cathodic arc and/or magnetron sputtering sources. It’s designed to meet manufacturing needs in cutting and forming tools, precision-engineered components, automotive/aerospace parts, medical devices, and other functional components.

“Our new compact PVD system has been designed from the ground up for versatility, efficiency, ease of installation, use, and maintenance,” explains David Wayne, VaporTech commercial business director. “For more than 40 years, we have helped companies successfully bring PVD coating operations in-house, and this newest system brings greater capability and flexibility to deposit an even broader range of industrial coatings.”

System features include:

- Modern turbomolecular vacuum pumps for excellent pumping performance and lower power consumption.

- Advanced cathodic arc, sputtering, bias, and ion source power supplies to improve coating quality and system reliability.

- The compact system footprint is 2.1m x 4.8m, and all components are on one skid for easier transport and a faster, streamlined installation.

- Straightforward maintenance with dual chamber doors, easy-to-remove deposition shields, and quick access to all sources for target changes.

- The most recent version of our easy-to-use VaporTech coating system software interface.

For more information about the V.MAX1500 PVD system and how it can upgrade your operations, please visit our website.