Tackling the Core Challenges of Production Scheduling

Real-time scheduling solutions offer manufacturers the tools and insights needed to navigate the complexities of live production with greater ease and precision.

Posted: September 30, 2024

While a necessary evil in manufacturing, it’s surprising that scheduling has not evolved beyond the current standard. Many manufacturers continue to struggle with the complexities of scheduling, often due to the limitations of traditional tools and the unpredictable nature of the shop floor.

The problem appears to be twofold. (1) Scheduling is often done based on inaccurate data from an ERP or MES and (2) the schedule tends to be an inflexible guide due to downtime and other events that occur during production.

As effective as a production scheduler may be in incorporating the estimates and variables of shop floor activity, it is impossible to compensate for the many interruptions and challenges that will occur when the schedule finally meets production.

As one machine shop shift lead describes it: “Our weekly schedule comes from our ERP, is downloaded to Excel, manually reviewed to prioritize certain jobs, and then sent to tablets where a person can make a work order. We also have other schedules throughout the shop that change every hour of the day. Yeah, it’s a crapshoot system.”

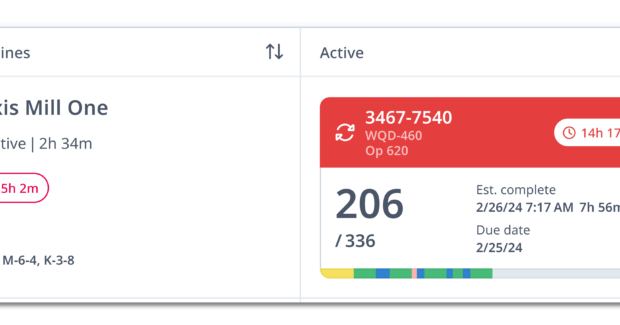

Another manufacturing engineer commented on the issue, and its downstream effects: “It’s very difficult for us to see how a delay, such as a slow setup, will impact subsequent jobs scheduled on that resource. When dates are missed, our system doesn’t update or display the impact. We need a more dynamic system to see the impact in real-time.”

Manufacturers need a schedule that is based on real time, accurate data, and they also need systems that accommodate and adjust to shop floor hiccups to ensure they can still reach on-time delivery.

Key Challenges in Production Scheduling

The demand for faster production and higher degrees of customization continues to push the industry forward, challenging manufacturers to be more efficient and agile. While this is certainly a challenge, it’s also an opportunity for those who can find solutions to meet the market demand.

Here are a few of the core challenges with modern-day scheduling:

- Complexity of Production: Today’s manufacturing processes are more complex than ever before, involving intricate, multi-step workflows that require precise coordination — not to mention the higher expectations of customers. As production lines become more sophisticated, ensuring that each step is scheduled correctly and that resources are available when needed becomes increasingly difficult.

- High-mix, Low-volume Production: The shift towards customized products and smaller batch sizes adds another layer of complexity to scheduling. High-mix, low-volume production requires frequent changes to the schedule, making it harder to maintain efficiency and meet delivery deadlines. Traditional scheduling tools struggle to accommodate this level of variability, often leading to bottlenecks and delays. After all, new product profiles will not offer the historical data to dial in estimates such as cycle times.

- Unpredictable Shop Floor Dynamics: The manufacturing environment is inherently unpredictable. Equipment failures, material shortages, and workforce issues can arise at any time, disrupting the production schedule. Without real-time visibility and the ability to adjust on the fly, these disruptions can lead to significant downtime and missed deadlines. What’s worse is that this generally has a ripple effect that impacts not just the current job, but also all the ones behind it.

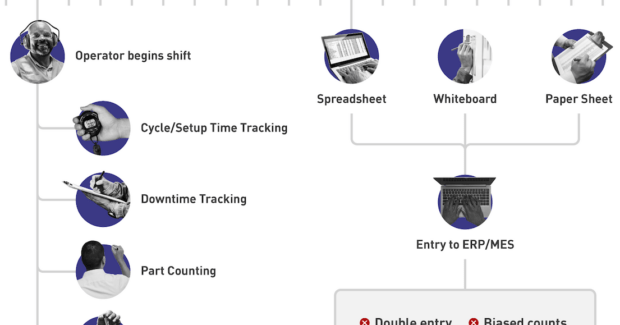

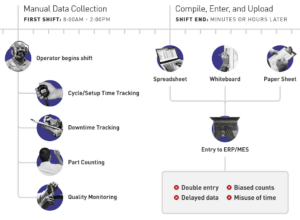

- Manual Data Entry and Errors: Many manufacturers still rely on manual data entry to monitor production and manage schedules. This is not only time-consuming but also prone to errors, resulting in a highly inefficient and inflexible schedule.

- Disconnected Systems: There tends to be a large gap between management systems that generate the schedule, and what actually occurs on the shop floor. The poor feedback loop between the two results in a schedule that does not stand up to the activities and unpredictable nature of the shop floor. A better feedback loop is needed.

Addressing the Challenges with Modern Solutions

While the challenges of production scheduling are significant, they are not insurmountable. Modern scheduling solutions that leverage real-time data and advanced analytics are increasingly being adopted to address these issues. These systems offer dynamic schedule optimization, real-time adjustments, and seamless integration with other manufacturing systems, providing manufacturers with the tools they need to overcome the limitations of traditional scheduling methods.

The result is twofold:

- The accurate, historical performance of the shop floor is properly represented when schedules are originally generated, ensuring that the schedule is as accurate as possible.

- The unexpected events of the shop floor are automatically represented on the live production schedule, ensuring that shop floor personnel and management understand the status of work and can automatically pivot to deliver work orders on time.

The Role of Real-time Data in Modern Production Scheduling Solutions

Manufacturers are increasingly turning to advanced production scheduling solutions that leverage real-time data and predictive analytics. These modern solutions offer several key advantages over traditional methods:

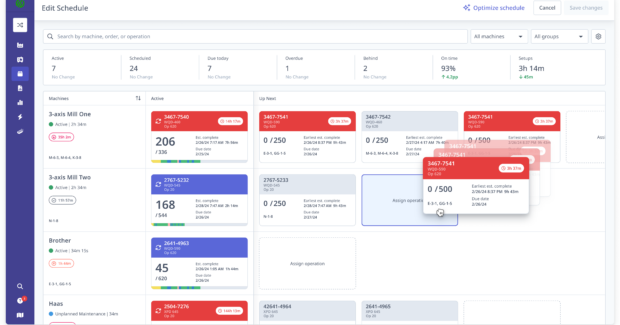

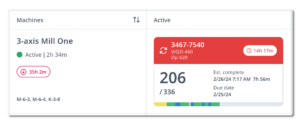

- Dynamic Schedule Optimization: Modern scheduling systems continuously assess operational data in real time, allowing for dynamic optimization of production schedules. By monitoring key metrics such as machine availability, job progress, and resource allocation, these systems can identify potential bottlenecks or delays and make adjustments to the schedule on the fly. This proactive approach minimizes disruptions and ensures that production stays on track.

- Real-Time Adjustments and Alerts: Advanced scheduling solutions provide up-to-the-minute estimates of job completion times for every machine on the shop floor. This real-time visibility enables manufacturers to make informed decisions about production scheduling and receive alerts when work falls behind schedule. By reacting quickly to these alerts, manufacturers can take corrective actions to avoid delays and ensure on-time delivery.

- Interactive Production Order Management: Modern scheduling systems often feature intuitive interfaces that allow users to easily move and sequence production orders. This interactive approach provides immediate feedback on the health of the schedule, enabling users to make real-time adjustments as needed. Once changes are made, they can be communicated instantly to all stakeholders, ensuring that everyone is aligned with the updated schedule.

Key Benefits of Implementing Real-time Scheduling Solutions

The integration of real-time data into production scheduling offers a range of benefits that can significantly improve manufacturing operations:

- Improved On-Time Delivery: By continuously optimizing production timelines based on real-time data, manufacturers can ensure that products are delivered on time, even in the face of unexpected disruptions. This not only improves customer satisfaction but also enhances the manufacturer’s reputation for reliability.

- Enhanced Efficiency: Real-time scheduling systems automate many of the manual tasks associated with traditional scheduling methods, reducing the risk of errors and freeing up staff to focus on higher-value activities. This automation also helps to eliminate bottlenecks and maximize throughput, leading to more efficient production processes.

- Proactive Schedule Management: Instead of reacting to problems as they arise, real-time scheduling solutions enable manufacturers to anticipate and mitigate potential issues before they cause significant disruptions. This proactive approach reduces downtime and helps to maintain a steady production flow.

- Operational Flexibility: The ability to make real-time adjustments to production schedules gives manufacturers the flexibility to adapt quickly to changing conditions, such as shifts in demand or unexpected machine breakdowns. This agility is critical in today’s fast-paced manufacturing environment.

- Improved Communication and Collaboration: Real-time updates and alerts facilitate better communication and collaboration across the production floor. All stakeholders, from schedulers to operators, are kept informed of schedule changes and can act promptly to maintain productivity.

The impact is seen across the organization. Schedulers can develop the initial production schedule with accurate data, operators know exactly which job to take on next, and shop floor leads can quickly take action when the schedule identifies key adjustments to make.

The Future of Production Scheduling in Manufacturing

As the demands of modern manufacturing continue to evolve, the ability to quickly and effectively adapt to changes on the shop floor is becoming increasingly critical. Real-time scheduling solutions offer manufacturers the tools and insights needed to navigate the complexities of live production with greater ease and precision.

By leveraging these advanced solutions, manufacturers can create production schedules that are not only accurate and reliable but also flexible and responsive to inevitable disruptions. This adaptability leads to more efficient and productive operations, positioning manufacturers to thrive and maintain a competitive edge.