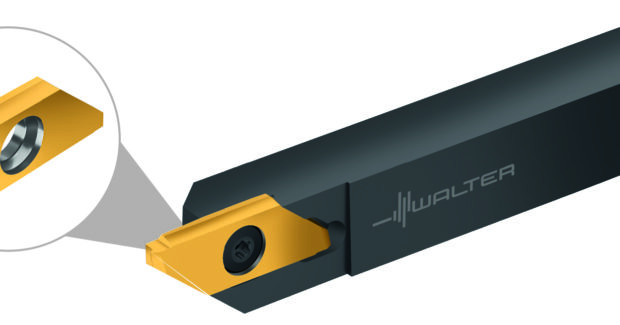

New Indexable Inserts and Tool Holder System for Parting Off/Grooving and Swiss Turning

The Walter WT26 inserts provide maximum sharpness for ultimate precision in small part machining and Swiss turning.

Posted: September 26, 2024

Walter has introduced WT26 indexable inserts along with a Swiss toolholder system in which the insert screw can be accessed from both sides for simple indexing. The tangentially installed and precision-ground WT26 indexable inserts are for turning and parting off/grooving parts starting from a workpiece diameter of 0.039″ or 1 mm.

The toolholder system is for use on Swiss turning lathes and multi-spindle machine tools. The inserts feature sharp periphery-ground cutting edges to achieve optimum machining results even at low feed rates. A chip breaker groove ensures ultimate precision. The available shank sizes are ½”, 5/8″, 10 mm × 10 mm, 12 mm × 12 mm and 16 mm × 16 mm.

The sharp zero radius inserts are available in two grades: WSM23X coated carbide and WN23 uncoated carbide. The thin PVD-coated, grade-WSM23X inserts are suitable for machining steels, stainless steels, heat-resistant super alloys and similar materials with difficult cutting properties, and non-ferrous metals (ISO P, M, S and N workpiece groups).

The primary application for the extremely tough and abrasion-resistant uncoated carbide grade, WN23, is machining non-ferrous metals (ISO N). The secondary applications are machining steel, heat-resistant super alloys and other

non-ISO materials, such as carbon fiber-reinforced plastic and carbon fiber composites.

Applications for each insert grade include grooving along close shoulders thanks to the installation of the cutting insert at a 1° angle and tight-tolerance components. All WT26 indexable insert types fit in the same toolholder to enable a high level of flexibility.

The geometries include the DG8 chip breaker for forward turning, the GD8 chip breaker for grooving, the VG8 chip breaker for reverse turning and profiling (copy turning), the CD8 chip breaker for parting off, the RA8 chip breaker for full radius grooving, the UA8 chip breaker for grooving and groove-turning, and the ISO full-profile thread geometry.