Glencore Improves Recycling Plant Safety with ELOKON Automated Forklift System

New case study shows how Rhode Island facility uses ELOshield on its forklifts to increase awareness and hazard perception.

Posted: September 24, 2024

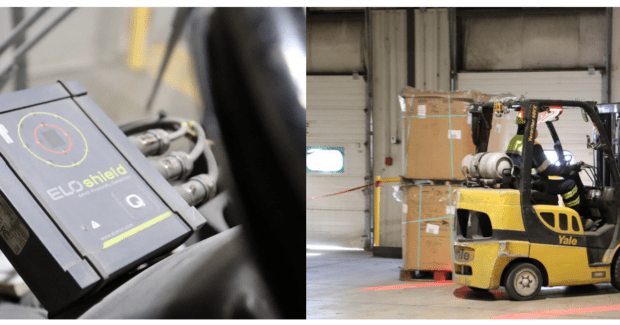

Glencore, a global leader in commodity trading and mining, has reduced safety incidents involving forklifts at its recycling facility in Rhode Island with the use of the ELOshield proximity detection system from ELOKON, Inc., a leading innovator in automated forklift safety and fleet management systems. In a new case study, Glencore discusses how it chose ELOshield to retrofit its forklifts due to the system’s advanced warning capabilities, especially in areas with limited visibility.

Glencore equipped all forklifts and personnel, including visitors, with ELOshield, which uses 2-way ranging ultra-wideband (UWB) proximity detection to warn operators when any pedestrians, objects or other vehicles are too close.

In Rhode Island, 35 employees work on shredding electronic materials, reducing particle size, and preparing samples for smelting and refining at the Glencore recycling facility. The complexity of the process combined with the high volume of forklift traffic and the close proximity of pedestrians in a small environment presented safety challenges that required a proactive technical solution.

“Since we installed ELOshield, we haven’t had any significant incidents involving forklifts,” said Juan Carlos Molines, plant manager, Glencore. “The system has increased everyone’s awareness and hazard perception, making our facility much safer.”

Glencore equipped all forklifts and personnel, including visitors, with ELOshield, which uses 2-way ranging ultra-wideband (UWB) proximity detection to warn operators when any pedestrians, objects or other vehicles are too close. The system’s adjustable alert distances allowed for customized safety zones tailored to specific facility needs. This flexibility ensured comprehensive protection for everyone on site.

“From the start, it was clear that Glencore was fully committed to the safety of its workers,” said Mark Stanton, ELOKON Inc. president and general manager. “With so many forklifts and employees working in close proximity, being able to keep all parties alert and aware at all times is of utmost importance. That’s what Glencore gets with ELOshield.”

To read the full case study, visit https://www.elokon.com/en-US/references/eloshield-enhances-forklift-safety-for-glencores-recycling-facility

Forklift Accidents and National Forklift Safety Day

According to the National Safety Council, forklifts were the cause of 73 work-related deaths in 2022 and 24,960 non-fatal injuries in 2021-22. To reduce these incidents, and raise awareness of the safe use of forklifts and the importance of proper operator training, the Industrial Truck Association (ITA) founded National Forklift Safety Day in 2014 in the United States. The 11th annual event is now a hybrid conference featuring forklift manufacturers and experts speaking about the safe use of forklifts, the value of operator training and the need for daily equipment checks. The in-person event is held today at the National Press Club in Washington, D.C., but those unable to attend can register to watch the live stream here.