ANCA and Tetralytix Announce Strategic Partnership for Virtual Cutting Tool Design

Sophisticated digital interface solutions reduce development time and cost.

Posted: September 29, 2024

ANCA, a market leader in CNC grinding machines who is this year celebrating 50 years of innovation, and Tetralytix, a developer of simulation software for superior metal cutting technology, are pleased to announce their strategic collaboration in the field of virtual design for cutting tools.

This partnership leverages the combined expertise of both companies to offer unique capabilities for the development of superior precision cutting tools and enhancing metal cutting technology.

The collaboration integrates ANCA’s expertise in virtual modelling of tool geometries and industry-revolutionizing CIM3D tool verification software with Tetralytix’s expertise in technological analysis through Toolyzer, a simulation tool for designing and optimizing cutting tools. An interface between CIM3D and Toolyzer will enable cutting tools to be developed faster and more cost-effectively, providing significant benefits to tool manufacturers.

“ANCA welcomes this partnership as it signals our commitment to empowering our customers with the most advanced and powerful software tools available. By working together, we’re ensuring that cutting tool manufacturers have everything they need to innovate, optimize, and stay ahead in a rapidly evolving industry,” said Martin U. Ripple CEO at ANCA.

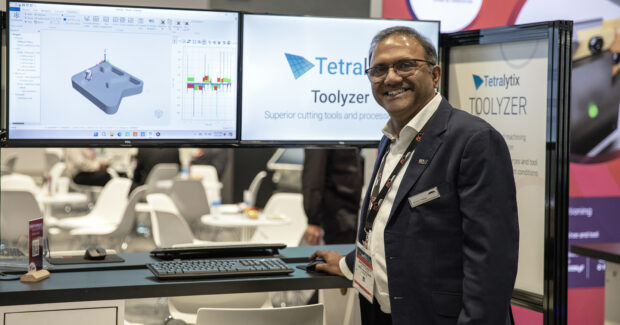

Dr.-Ing. Arne Mücke, Managing Director, Tetralytix, added, “The partnership with ANCA is a significant step towards creating added value and competitive advantages for our customers. The cooperation will make the benefits of digital cutting tool development visible in an unprecedented way.”

“ANCA understands the constant challenges for tool designers for achieving longer tool life and the demands to cut newer materials. With this partnership, our customers can seamlessly design a tool and access cutting analyses even before the first test cut. When ANCA first introduced CIM3D, customers couldn’t believe the sophistication of the solution and this is now the next revolutionary step in reducing tool development time and cost,” said Santosh Plakkat, Product Manager, ANCA.

This strategic cooperation is a significant step forward for the development of cutting tools, offering considerable cost advantages for both standard and special tools. The reduction in time-consuming, manual work to prepare digital tool models for simulation also significantly shortens development times.

Untapping development potential to optimize tool design

Testing multiple tool prototypes is time-consuming and cost-intensive, ANCA and Tetralytix recognize that the time has come to leverage this potential with the help of a continuous interface from tool modelling to simulation.

The tool is designed using ANCA’s iGrind software and can then be used seamlessly in Toolyzer for analysis.

Within a brief time, performance conclusions can be drawn, and recommendations for improving the tool geometry can be derived. This enables users to determine whether a tool prototype meets the requirements even before it is produced for the first time.

About ANCA

ANCA is a market-leading manufacturer of CNC grinding machines. The company was founded in 1974 in Melbourne, Australia, where it still has its global headquarters. ANCA CNC grinding machines are used for the manufacture of precision cutting tools and components in a wide range of demanding industries including cutting tool manufacturers, power generation, woodworking, automotive, aerospace, electronics and medical.

About Tetralyti

Tetralytix is a leading provider of simulation solutions for the machining industry. Tetralytix develops practical software solutions based on in-depth knowledge of production engineering and computer science as well as practical experience in machining. With Toolyzer, users can optimize both cutting tools and entire machining processes quickly and easily. In addition to complicated multi-axis processes, special processes and procedures such as gear skiving and gear hobbing are also supported.