Wire EDM for the Job Shop Masses

EDM generators categorized as “intelligent” are digital and monitor every single spark while working in unison with today’s adaptive control human machine interfaces that increase machine productivity.

Posted: August 28, 2024

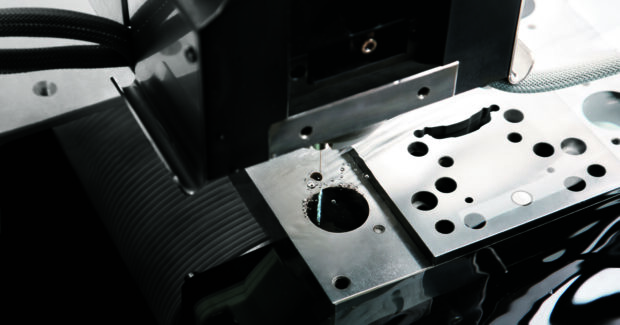

A wire electrical discharge machine (EDM) that consistently cuts at a +/- 0.00025” accuracy and generates surface finishes as fine as 0.3 Ra is more than capable for 90% of the EDM jobs shops are doing. If part requirements fall within those parameters, shops should consider a cost-effective, yet high-performance, EDM with those capabilities as opposed to purchasing too much machine for parts that really don’t warrant it.

While many cost-effective EDMs in the market today provide the sweet-spot accuracy and surface finish levels, there are differences, specifically when it comes to control and generator features and functions. EDM generators categorized as “intelligent” are digital and monitor every single spark while working in unison with today’s adaptive control human machine interfaces that increase machine productivity.

Thanks to the intuitive workflow and a short learning curve of adaptive controls, they simplify the lives of operators by adapting to their way of working and offering the possibility to change the programs on board as well as a flexible management of the shop itself. Additionally, readily available integrated help and tutorials make the controls easy to use not only for operators accustomed to ISO programming or dynamic-type programming but for seasoned users, as well as beginners.

As part of their adaptive controls, some wire EDMs designed for the job shop feature handheld remote controls. The devices often have many of the most commonly used functions but also allow the operators to be close to the machine and workpiece, for example: when having to run an indicator back and forth across a part surface. They can manually jog the machine axis while also watching the part.

Because of today’s control technology, some job shop EDMs allow for “batching” to reduce job setup times. With such capability, shops load multiple parts/jobs on every available area of the worktable, and the control batching function makes it easy to cut all the parts completely unattended and overnight.

Other wire EDMs can do batching. However, they do so using G-code programming, which makes it a bit difficult to manipulate programs for handling multiple parts. For example, consider four separate parts mounted on the worktable from left to right and numbered from one through four. The operator then needs to switch the program to work from left to right instead of right to left. This is a huge change to undergo in a conventional G-code program. Such a switch is easy with newer advanced control technology and is simply a matter of re-sorting which workpiece to cut first.

For shops in the mold and stamping die industry for instance, such control capability would let them re-sort die plates based on minimum operator time. Those shops could simply click a button, and the control automatically re-sorts all the cavities and workpieces to minimize the need for operator intervention to remove slugs from cavities.

The worst thing a shop could do is load a machine’s worktable full of parts and process them using one huge program because problems arise when a modification is necessary. In those instances, the change is often complicated and time consuming. To avoid this, shops will use sub programs within the main program, but that, too, often proves cumbersome when it comes to modification. Today’s controls eliminate these problems.

Consider a shop that loads four die plates on the EDM’s table, and each plate requires four cavities cut in them for a total of 16 cavities. If each cavity takes 30 minutes, total burn time is eight hours, and at the end of that time, an operator would need to be there to remove the slugs. Or, the shop could rough out all the cavities in each plate, remove all the slugs then do all the finish passes unattended. Either scenario would involve a different machine program. Whereas with advanced controls, users could simply flip a switch to select either one of those scenarios.

Operators would program the job how they would normally, but in the control, they would have the ability to not only re-sort, but also change the way the machine cuts the parts. With such capabilities, today’s controls bring more efficiency to cost-effective EDMs, especially those designed specifically for job shops.

One such machine is the CUT E JobShop Series of wire EDMs from GF Machining Solutions that offer many options to enhance machine production and performance. Some of those options include: Taper Expert for higher-accuracy tapers; the addition of a rotary axis for increased part processing flexibility; 3D Setup to reduce setup time; TurboTec for optimizing speed in diverse flushing conditions; a larger wire spool capacity up to 25kg; automatic slug welding and many others.

While CUT E JobShop machines get their accuracy and surface finish capabilities from the company’s new Uniqua control and IPG technology, the GF Machining Solutions JobShop design involves certain changes and the elimination of certain components to reduce the machine’s cost — even more so than its predecessors. The first change was the incorporation of swing-type doors as opposed drop-style doors. While drop doors are advantageous in certain situations, not all job shops really need the feature. In fact, when it comes to job shop type machines, swing door designs are typical. But, if a shop wants a drop door, they can get one on their machine as an option.

Another cost reducing change is the incorporation of a pedestal-type control stand as opposed to one mounted on the machine. The pedestal allows shops to move the control anywhere they want as opposed to a machine mounted pedestal that offers limited swing/movement.

When it came to axis travel sizes, GF Machining Solutions designed the machines with U/V travels of 2.6” in both the + and – directions, which allows shops to generate angles up to 15°. This means machines can do form tools, mold work and stamping dies requiring 2° of taper or more.