Weighty Considerations Before Expanding into 3D Printing

Latest automated equipment helps metal fabricators tap growth potential of additive manufacturing.

Posted: August 22, 2024

Metal fabricators poised for growth in the coming years, who may be considering investing in 3D printing equipment to tap into the projected $50 billion additive manufacturing industry, may be in for a surprise.

Expanding into 3D printing and efficiently integrating it into an existing operation isn’t as simple as expanding the range of services with a new laser cutting machine, welding workstation or press brake. Metal additive manufacturing involves a completely different set of machinery and auxiliary equipment than traditional metalworking and comes with a completely different set of safety risks and physical infrastructure requirements that need to be considered.

Metal fabricators typically base their operations on working with bar stock, sheet metal, ingots, and other solid metals for subtractive processes that remove material such as machining, cutting and tapping. Additive manufacturing reverses the process by starting with fine metal powders and layering them into a solid part. Because most fabricators lack experience in handling, storing, and working with bulk powders, they may also lack an understanding of their inherent dangers.

Metallic powders such as cobalt, tungsten, aluminum, copper, Inconel, stainless steel, and others commonly used for 3D printing are toxic in varying degrees and milled to very fine particle sizes in a 20-to-45 micron range that must not be inhaled. These powders are also ignitable and labeled combustible in the forthcoming NFPA 660 Standard for Combustible Dusts and Particulate Solids Chapter 12 covering combustible metals. Failure to address these dangers in advance could result in serious worker injury and disease and/or a catastrophic explosion.

The 3D printing process involves the following steps:

- Loading material to the printer from a container, IBC, supply hopper or other storage unit.

- Unloading excess powder from the build box after printing.

- Collecting and screening the excess powder to remove agglomerates.

- Returning the screened material to storage for future reuse or directly to the printer for the next build.

Each step creates opportunities for metal powder spillage, release, and toxic exposure to workers and to the plant environment. In addition to the risks to personnel, these exposures also risk contaminating the metal powder. Ambient moisture and humidity, dust, dirt, and particulates from nearby machining operations, and cross-contamination from other materials lead to serious consequences. These contaminants may cause poor flowability, corrosion, poor bonding between layers, and a variety of part defects from reduced strength and porosity to uneven surface finishes and otherwise weakened parts that may not meet quality specifications. Such parts become a costly waste of time and powder. Depending on the material, even exposure to oxygen can render the metal powder as unusable waste.

Automation Creates Efficiency in 3D Printing

When metal additive manufacturing began in its infancy, the process often required transporting the metal powders from storage containers by forklift or by hand to the 3D printers where workers then handled the loading into the build box manually while suited up in full hazmat gear. After printing, the same workers manually unloaded and collected the excess or unused material and brought it to a screener, then collected it in a container for storage, reuse or disposal. In addition to the alarming safety risks, this process can be termed highly inefficient and not at all likely to bring the cost per part down anywhere near the cost per part of a traditional fabrication process, given a comparable design. At a time when the metalworking industry continues to struggle with recruitment and retention, asking workers to spend their days in these conditions isn’t likely to lead to success in hiring.

Now that the industry has begun to mature, a slate of automated metal powder handling solutions is available to address the safety risks, improve production efficiency, and protect the powder purity for consistent, high quality parts. These automated systems were developed in a research collaboration among BMW, GKN Additive, and Volkmann GmbH of Soest, Germany, and are available in North America via Volkmann USA. In devising the additive manufacturing equipment, Volkmann’s engineers drew on the company’s several decades of experience in designing and manufacturing automated powder processing equipment, such as pneumatic vacuum conveyors, bulk bag unloaders, vibrating feeders, and lump breakers for the safe, smooth transfer of hundreds of different chemicals, food ingredients, small components, and other bulk products and materials.

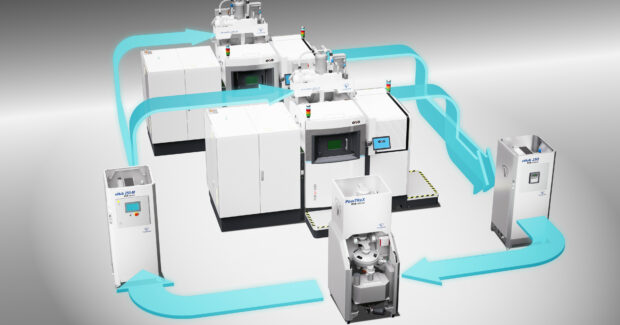

As an example, Volkmann’s flagship system for fully automating the 3D printing process features a closed loop concept that integrates all of the steps involved in transforming powdered metal material into structurally strong, durable, printed parts into one safe, efficient, contained system. Material is transferred from storage into the printer (or into multiple printers) via a loader that consists of a pneumatic vacuum conveyor, patented vacuum pump, filter, and accessories installed onto or alongside any manufacturer’s 3D printer. At the press of a button, the system automatically transfers the metal powder through fixed piping or flexible hose up to 25 meters away and up to five meters of vertical elevation to discharge into the build box.

After printing, a depowdering station automatically cleans excess powder from the part and from the build box. Entirely within a sealed chamber, a proprietary combination of compressed air or inert gas, gravity, and a vibratory action remove any material left on the part and inside the build box and frame. The station leaves the build box pristine and ready for the next job and discharges the part ready for any secondary finishing operations. The cleaning cycle may take 10-to-30 minutes, depending on the part.

Another system, for powder transfer, recovery and extraction automatically extracts the excess metal powder from the build box via a vacuum conveyor, then sieves it through an ultrasonic screener to remove any fused bits of metal

agglomerates. Oversized particles are collected and separated from the process while on-spec material may be either returned to the printer for immediate reuse via another vacuum conveying tube or pipe or stored in a storage vessel.

The storage vessel serves as a buffer container to hold extracted powder after screening and/or while waiting for a printing cycle to finish. To ensure the moisture content of the powder meets the required specifications, a vacuum dryer automatically restores metal powders that have absorbed ambient moisture during storage or transport to the proper moisture content value. It may be integrated in multiple points in the process both upstream of the printer to address virgin material and downstream to address excess material extracted after printing.

This type of closed loop approach automatically streamlines the process versus manual handling, reduces the number of operators involved in the process, and minimizes the fixed costs of offering 3D printing at the outset. As a contained system, it eliminates the potential for material contamination due to exposure to the environment, eliminates dangerous contact between workers and toxic powders — along with the need for hazmat-style PPE — and eliminates concern for material spillage into the workplace. Manual handling of heavy storage containers is also eliminated along with the need for forklift traffic to manage powder transfer to the printers. Further, the Volkmann pneumatic vacuum conveyors and associated equipment are explosion-proof by design and ATEX-certified documenting protection from such a catastrophic event.

Additive Manufacturing As a System, Not Just a Printer

Many additive manufacturers began the process of offering metal 3D printing with a focus on purchasing the ideal 3D printing machine to produce existing parts faster or to position the company for a future that seems to arrive more quickly every day.

While purchasing the appropriate printer is certainly critical, determining the appropriate powder handling system to keep the printer printing rather than sitting idle is equally critical to recouping the investment in the latest technology. Unfortunately, a number of AM managers have neglected to consider powder storage, transfer, and recycling early in the process and have struggled to create space in the facility for the 3D printing machinery and infrastructure, to keep the operation fully staffed, and to capture the promise of fast, efficient, low-cost production. Using a manual powder handling approach, for example, typically requires a separate room or area for printing to prevent the metal powder from contaminating other work in process or other metal material stocked in inventory.

When considering offering metal additive manufacturing in the range of metalworking services, it is useful to involve engineers with expertise in powder handling for 3D printing early in the process. This helps to avoid costly and potentially dangerous errors and ensures the new service may begin generating ROI as quickly as possible.