Quality Assurance

From CMM’s to automation systems, quality assurance will be on display at IMTS in Chicago.

Posted: August 1, 2024

Five-axis CMMS, new Flexible Gauging System and Versatile Scanning Option

Automation, advanced data analytics, growing demand for in-process measuring and increasing focus on precision manufacturing are reshaping metrology’s role in manufacturing. These industry trends prompted Advanced Industrial Measurement Systems (AIMS) Metrology (Dayton, OH) to expand its product offering and launch plans to open a new Southeast Technical Solutions Center in North Carolina in the fall of 2024.

At IMTS in Booth E-134342, the OEM will demonstrate multisensor inspection with its range of turnkey 5-axis coordinate measuring machines (CMMs).In addition to its Revolution Series 5-axis HB and LM CMMs, visitors will be able to see AIMS’ newest addition in flexible measuring systems — the Itaca FlexGauge.

Unlike traditional hard gauging setups, the high-performance, cost-efficient Itaca FlexGauge is suited to applications that require tactile scanning for small, high-precision parts. AIMS’ lab-grade LM offers multisensor capabilities with REVO-2, which provides measuring speeds up to 500 mm/second and data collection rates of up to 4,000 points per second for increased part throughput. The mobile HB, fitted with a 5-axis PH20, can be placed on or near a production line to provide dimensional verification and process flow monitoring in real time. Other demonstrations include the SP25M, a compact, versatile scanning probe system. Its compact size [25 mm in diameter] supports a range of scanning and touch-trigger modules. Its slim profile and auto joint mounting make it suitable for use on the PH10M probe head. AIMS will showcase a fully retrofitted machine equipped with the SP25 and a CMM Vision Probe [camera] to demonstrate its capacity for multisensor inspection on the same system.

Unlike other OEMs, AIMS tailors its CMMs to customers’ software requirements with CMM-Manager or MODUS. “We have an in-house service group and application team that allows us to customize the right measurement and inspection solution to a job shop or manufacturer’s needs,” said Thomas Ayers, sales and business development director (Southeast) for AIMS. “That includes programming, custom holding fixtures, tooling, automation, service and support. With the current economy, labor shortages, and lead times for new and leased equipment continuing to grow, companies need versatile options. They also need a service provider they can depend on.”

New Technology for Automation, Tool Monitoring and Process Control

Caron Engineering, Inc. (Wells, ME) is excited to showcase its latest technology for automation, tool monitoring, and process control in Booth E-134742. In addition to unveiling exciting new features for its flagship TMAC-Adaptive Tool Monitoring System, AutoComp-Automated Tool Wear Compensation Software, and ToolConnect RFID Tool Data Management System, Caron Engineering will introduce its latest automation solution, MiConnect Technology.

MiConnect streamlines connectivity and control across the devices in your machining cell, for total control of your processes from a single interface. From a simple operation of parsing a few pieces of meaningful data to handling all inter-device communication across a fully automated cell, MiConnect can easily be configured for your desired process and flow. The MiConnect platform contains an inventory of pre-built manufacturing devices (CNCs, robots, gauging devices, barcode scanners, I/O, Modbus, files, SQL, REST API, etc.) and numerous building blocks of operations that can be designed to control any manufacturing process.

Caron Engineering will also demonstrate a fully automated production cell featuring a FANUC Robodrill equipped with two FANUC cobots, a MiJet air-actuated parts cleaner, a Fowler CMM, and automated ID thread gauge. The Caron Engineering integrated technology you can expect to see automating and controlling the lights-out machining cell include:

- ToolConnect RFID Tool Data Management System will be automating the process of loading tools into the machine by automatically transferring preset tool data directly to the CNC control, which reduces setup time and eliminates error.

- During cutting, Caron Engineering will feature its adaptive tool monitoring system, TMAC, optimizing cutting by measuring tool wear and detecting breakage in real time, while simultaneously monitoring tool and spindle vibration. Using adaptive control TMAC will adjust feed rates in real time to reduce cycle time up to 60% on some cuts.

- MiConnect Technology will be controlling the entire post-process automation cell to handle communication between the FANUC Robodrill, cobots, MiJet, Fowler CMM, and automated ID thread gauge.

- AutoComp software will read both the CMM and ID thread gauge measurement data, and automatically calculate and compensate offsets in the control, eliminating error and closing the loop on the automation cell.

- Caron Engineering’s customizable Smart Light system will be used as a visual indicator on the machine to display the current progress of production.

- Other exciting technology will include the new RFID User Authentication System (powered by MiConnect Technology) for customized user access to both the physical and software systems on the machine.

Caron Engineering’s smart manufacturing solutions are renowned for their versatility and seamless integration with almost any CNC machine tool.

Innovation Elevates Portable 3D Scanning Capabilities with Enhanced 3D Scanner

Creaform (Lévis, QC, Canada), a business of AMETEK, Inc. and worldwide provider of automated and portable 3D measurement solutions, unveils its next-generation scanners with the introduction of the HandySCAN BLACK+™️|Elite, and the complete redesign of the HandySCAN SILVER™️ and HandySCAN SILVER™️|Elite. These latest iterations of the BLACK and SILVER Series promise superior precision as well as enhanced user experience. Creaform will be in Booth E-134250.

The new HandySCAN BLACK+™️|Elite provides a superior level of accuracy through the use of the Accu+ Kit, enabling the user to confidently rely on an optimized volumetric accuracy of 0.020 mm+0.015 mm/m. Boasting the new Flex Volume, it provides a greater scanning measurement volume, and allows for an adjustable scanning distance that is simple to use, from near (200 mm) to far away (700 mm). Leveraging its newly acquired certifications, the BLACK Series also ensures precision and measurement reliability through its VDI/VDE 2634 part 3 and ISO 10360-based sensor acceptance tests in its ISO/IEC 17025-2017 accredited laboratories, underscoring Creaform’s commitment to rigorous performance evaluation and quality assurance.

As for the newly revamped SILVER Series, it emerges as a transformative tool in product development. With a new ergonomic aesthetic, its heightened resolution catering to intricate details, versatile scanning capabilities accommodating various surface types, and user-friendly design accessible to all, the SILVER series still offers the most value for money. Without compromising affordability, it integrates the cutting-edge advancement of the BLACK Series, leveraging a proven design, compatibility with the recently launched automation kit and benefiting from exceptional customer service and worldwide support.

As Simon Côté, product manager at Creaform, emphasized: “We are more than a simple solution provider, we partner with companies to improve our products based on their feedback, ensuring that they get the most out of our 3D scanning technologies and software and get to experience innovation firsthand. With these enhancements in the BLACK and SILVER Series, we provide a complete development path from beginner to expert, in a single lineup; the same that made us pioneers in self-positioning 3D laser scanners.”

New CMMs, Advanced Metrology Software and Related CMM Accessory Products

LK Metrology, Inc., (Hudson Heights, MI) a leading global designer and manufacturer of Coordinate Measuring Machines (CMMs), metrology software and associated CMM accessory products, will be exhibiting a variety of new products in Booth E-134338.

LK Metrology, Inc., (Hudson Heights, MI) a leading global designer and manufacturer of Coordinate Measuring Machines (CMMs), metrology software and associated CMM accessory products, will be exhibiting a variety of new products in Booth E-134338.

Five different CMMs will be displayed and demonstrated including: the new shop floor ready LK ALTERA SF equipped with an SLK25 Laser Scanner; the ALTERA S SCANtec 5 equipped with a Renishaw REVO-2 5-axis scanning system; the new ALTERA C HA high-accuracy CMM; the ALTO 6×5 Bench Top CMM equipped with a PH20 probe; and finally, a manual ALTO 6.5.5.

LK will also be demonstrating the newest version of its well-known CAMIO measurement, programming simulation, analysis and reporting software. In addition, the new Industry 4 Metrology Gate, LK’s portal for remote inspection monitoring, and the advanced version of

TouchDMIS CMM software will also be shown and demonstrated. Other CMM software like Renishaw Modus, Polyworks, and CMM Manager that are frequently used with LK Metrology CMMs, will also be available for demonstration.

Related accessory products to be seen will include LK’s new TSRS-5-Port Storage Rack, the Styli Cleaner, and LK’s CMM Checking Gage.

Full Range of Leading Metrology and Automated Wireless Data Collection Solutions

The L.S. Starrett Co. (Athol, MA), a leading global manufacturer of precision measuring tools and gauges, metrology systems and more, will be demonstrating the latest in quality control inspection technology in Booth E-134130.

Supporting Industry 4.0, IoT and the Digital Factory, attendees can see a unique, all-new touch screen wireless digital indicator that is highly accurate, fast, intuitive, easy-to-use and rugged, and demonstrations of automated wireless measurement data capture and transmission from other handheld wireless/electronic gauges via the DataSure® 4.0 Wireless Data Collection System, or from vision systems and optical comparators via integrated software.

Among the wide range of Starrett solutions to be highlighted at the show will be the debut of the innovative No. W4900 Wireless Digital Indicator, a precision digital measurement gauge featuring touchscreen technology. It redefines comparative indicating measurement, and is an intuitive, fast, easy-to-use gauge.

Special custom gauge solutions and force testing systems, as well as precision granite solutions, gauge blocks and more, will also be showcased. The vast majority of products to be featured in the booth are made in the U.S. with U.S. and globally sourced materials.

Also at the booth, Starrett will feature the new AVR400 Multi-Sensor Vision System, which features a choice of optics as well as touch probe options. The system is ideal for repetitive measurements and automatic comparison to CAD files. A horizontal digital video comparator combining vision and optical comparator technology will also be demonstrated, featuring a patented interchangeable lens mounting system coupled to a high-resolution 5 mega-pixel digital video camera. In addition, digital overlays in the system are developed directly from DXF CAD files. The industry leader in rugged, accurate and reliable optical comparators, Starrett will also showcase its HD400 Benchtop Comparator with a MetLogix Mx200 Digital Readout, which combines an intuitive user.

Starrett will also demonstrate its force testing systems, highlighting a flexible, customizable architecture that enables the range of Starrett software programs to be compatible with its different test frames.

Rounding out the measuring solutions will be Starrett Tru-Stone engineered granite metrology bases featuring the Superior Red air bearing/solid machine foundation base, gauge blocks, surface roughness testers and special gauging capabilities. Attendees are invited to bring their gauging and metrology challenges to the booth where Starrett engineers can provide technical support and guidance on pursuing customized solutions when conventional solutions will not suffice.

New Automation System Solution to Debut at IMTS

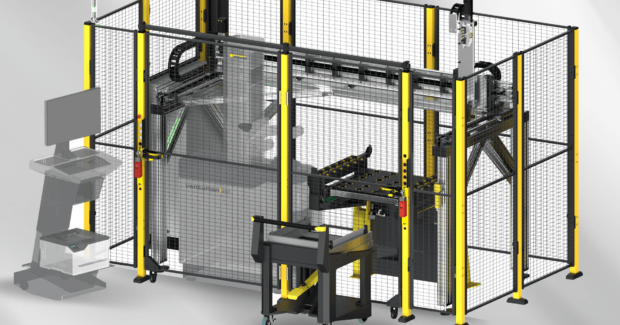

ZOLLER Inc. (Ann Arbor, MI) will premiere its new automation system and showcase its complete range of manufacturing efficiency solutions at Booth W-432018.

Making its North American debut at IMTS is ZOLLER’s new »coraMeasure LG« automated tool measurement system. This system delivers tools assembled in a pallet system to a linear robot that loads the tools into a ZOLLER »venturion« presetting and measuring machine, saving time, preventing errors and reducing the human workload.

“The debut of the »coraMeasure LG« at IMTS 2024 underscores ZOLLER’s dedication to producing innovative solutions for the biggest challenges facing manufacturing,” said ZOLLER Inc. President Alexander Zoller. “This new automation system addresses the industry’s critical labor shortage and introduces a more efficient, precise and reliable tool measurement process.”

Also at the show, ZOLLER will display its integrated systems for tool presetting, measuring, inspection, heat-shrinking, balancing, tooling, tool management and automation.

For the first time at IMTS, ZOLLER will present the »torquematic« presetting and measuring machine with a torquing station, alongside its popular »smile«, »venturion« and »redomatic« lines.

In addition, ZOLLER plans to unveil updated designs of its »toolOrganizer« and »twister« smart storage solutions.

The company will also highlight its »zidCode 4.0« with expanded »z.DMI« technology. This direct machine interface system provides a secure method for transferring data from a presetting machine to different CNC machine tool controls, all without stopping the CNC machine.

ZOLLER technology returning to IMTS includes the »roboSet 2« for automating tool cleaning, inspection, laser marking and loading, as well as the »powerShrink« heat-shrink machine and »toolBalancer« tool balancing system.

Additionally, the winners of ZOLLER’s first-ever Toolroom of the Year competition will be announced in a ceremony at 2 p.m. on September 12 at the company’s booth. The inaugural contest spotlights companies that have implemented optimized, automated processes around their cutting tools.