IMTS-Fabrication & Lasers

The latest laser and fabrication technology will be showcased at IMTS 2024.

Posted: August 1, 2024

Advanced Ergonomic Tapping, Drilling, Balancing and Material Handling Arms

Flex Machine Tools (Wapakoneta, OH), an American manufacturer and leading provider of machine tool solutions worldwide for metal fabrication operations and more, will be demonstrating tapping, drilling, balancing and material handling arm products in Booth E-135204. IMTS 2024 marks the 40th year anniversary since Flex debuted its first tapping arm at IMTS in 1984.

Highlights this year will include the flexible FlexArm REM-24D Electronic Tapping Arm with a multi-position head that allows quick and easy switches between vertical and horizontal tapping. Renowned for its ability to produce accurate tapped holes while minimizing the risk of tap breakage, the REM-24D Electronic Tapping Arm has a maximum reach of up to 70″ (1,778 mm) and is designed for taps up to 7/8″ (22 mm).

The FlexArm Mag Drill Arm will also be demonstrated, showcasing how magnetic drilling can be simplified, while reducing operator fatigue and increasing safety and efficiency. The ergonomic FlexArm Mag Drill Arm offsets the drill’s weight by effectively reducing up to 75 lbs. (34 kg) of strain on an operator’s body. The arm provides a working range of up to 100″ (2,540 mm) of horizontal reach and 52″ (1,320 mm) of vertical stroke, resulting in precision and versatility across a broad range of drilling operations.

For eliminating fatigue and repetitive motion injuries when grinding, Flex will demonstrate its B-33-RG Balance Arm for handheld grinders, designed to fit the specific grinder make/model. The balance arm offers full range of motion similar to natural movements, and also extends the life of the grinding tool and abrasive product. The B-33-RG has a counterbalance capacity of one-to-25 lbs., a reach range of 1″- to-72″ and 90 psi air pressure.

Offering users twice the lift with half of the effort, Flex will also demonstrate its FlexArm Part Manipulator, an innovative material handling solution designed to optimize productivity and enhance safety. The FlexArm Part Manipulator can position parts, unload tools and hold workpieces. The tool is engineered to function in cramped workspaces where simple overhead cranes are not possible.

Innovative Hydraulic Press Solutions Including Automation, Custom Applications

Greenerd Press & Machine Co. (Nashua, NH) will highlight the company’s extensive hydraulic press and automation capabilities in Booth E-135304. Application experts and design engineers from Greenerd will be available to discuss specific user applications and press requirements.

Greenerd designs and builds custom hydraulic presses with automation solutions for a range of industries and applications. One example that demonstrates these capabilities which Greenerd will discuss at IMTS is an automated two-press, two-robot production cell that Greenerd designed, engineered, built and turnkey-installed that enables unattended production of large aluminum pressure vessels.

Using sensors to locate pallets of blanks that have been placed in a pallet staging area, the first FANUC robot picks a blank, detects and rejects any double-blanks, and transfers the blank to a fully integrated and automated blank lube station. That robot then picks a previously lubricated blank and loads it into a Greenerd deep-draw press with a 76” stroke.

A second FANUC robot then catches and transfers the formed parts to a second Greenerd press for a punching operation. The two-press production cell uses a centralized control station that sets the operating parameters of both presses and controls the action sequences of both FANUC robots. All equipment in the cell is automatically updated with new process parameters when changing between products.

Greenerd is a Tier 1 Industrial Authorized Robot System Integrator of FANUC America Corp., the industry’s leader in automated manufacturing equipment. The partnership gives Greenerd full access to the comprehensive offerings of FANUC robots including all models, training and support, providing state-of-the-art automation solutions in short time frames. Complete, fully integrated production systems can be provided including simple raw material feeding systems, and robotic solutions including loading/unloading the press, the ability to perform an optional secondary part manipulation or process, automated inspection of parts and stacking finished products for downstream processes. The scope of automation can also encompass part inspection systems ranging from small sensors to complex camera inspections, and temperature monitoring/control of press and non-press related systems. Streaming critical production data to and from the press is also offered.

Greenerd’s extensive line of hydraulic presses are available in a variety of styles ranging from gap frame and straight-side to die-spotting and forging presses, with unlimited size and tonnage capabilities. Greenerd has a long tradition of designing, engineering and manufacturing customized hydraulic presses with product handling solutions.

MC Machinery Systems to Showcase its Latest Machining Technology and new 3D Printer

In Booth S-338129, MC Machinery (Elk Grove Village, IL) will display its latest EDM and precision milling technology, including wire and sinker EDMs, machining centers and automation. Also featured will be the new Mitsubishi AZ600 wire-laser metal 3D printer, which melts welding wire with a laser beam to create high-quality 3D structures. MC Machinery Systems is a subsidiary of the Mitsubishi Corp.

Among the machines to be demonstrated are:

- With artificial intelligence (AI) adaptive control technology, the Mitsubishi SV12P and SG12 sinker EDMs optimize performance, improve productivity, reduce electrical consumption and accurately estimate machining time. The SVP Series features proprietary Mitsubishi technology that incorporates a state-of-the-art sensor to monitor the total amount of electrode contact area within the workpiece, allowing the system to automatically change power conditions based on real-time measurement feedback. Along with producing the most efficient burn, this technology results in up to 40% less electrode wear and an up to 30% reduction in machining time. The SV12P will be outfitted with Erowa Robot Compact 80 milling and sinker automation.

- The MV1200-R Mitsubishi wire EDM features the latest machine construction, submerged threading, fiber optic machine communication and power supply technology. As MC Machinery’s best-selling wire EDM, the MV-R series is known to be dependable and easy to use, spurring increased productivity and efficiency. This machine will be shown with the Mitsubishi Electric 6-axis robot automation system.

- Using commercially available welding wire as the feedstock, the Mitsubishi AZ600 has applications including rapid prototyping, mold and die, one-offs, short runs, mass manufacturing, maintenance, repair, tooling and more. With the same proprietary wire-feeding technology used in Mitsubishi’s industry-leading wire EDMs, a simple command on the machine’s CNC control feeds the exact amount of wire to the target location. Unlike other 3D printers, the wire is in the front of the machine to make it easier to replace.

For complete details about MC Machinery’s lineup at IMTS, visit www.mcmachinery.com.

Optimize Cutting with New Generation of Waterjet Systems

The OMAX Corp.’s (Kent, WA) OptiMAX 60X JetMachining Center is the most advanced waterjet system on the market with groundbreaking software, optimized cutting capabilities, more power, and better efficiency. The OptiMAX 60X is the culmination of three decades of engineering expertise for a new generation of waterjet systems that quickly turn prints into parts with reduced dependency on highly experienced operators.

Benefits of the OptiMAX 60X include:

- Cutting envelope of 10′-x-5’ 2”.

- Produce more parts with less water and garnet with the most efficient pump in the industry, the EnduroMAX direct drive pump.

- With powerful optimizations for faster, more precise cutting and predictable operations, IntelliMAX Premium is industry-leading software that is intuitive and easy to use and maximizes overall productivity.

- Patented maintenance-free IntelliTRAX drive system with micron-level encoders for positional accuracy.

- Get up to speed and stay there with free unlimited training for lifetime of ownership.

- Industry leading cutting speeds and precision.

- The OMAX Technology Guarantee entitles you, as the original owner, to free OMAX software upgrades for the life of the machine.

- Environmentally friendly technology cuts more with less.

- Largest abrasive waterjet support network in the world.

Like every OMAX system, the OptiMAX 60X includes comprehensive after-sales service, unlimited free training and software upgrades, as well as a host of efficiency centered resources to maximize uptime and keep customers cutting.

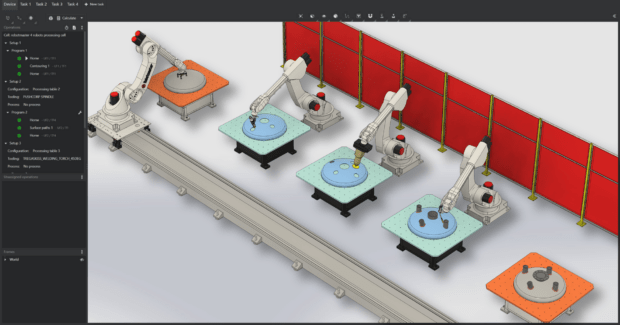

Robotic Offline Programming Software Supports Multiple Robots in a Work Cell

Hypertherm Associates (Hanover, NH), a U.S.-based manufacturer of industrial cutting products and software, announced the latest version of its offline programming software with the launch of Robotmaster® 2024. Hypertherm will be in Booth E-135020.

Addressing key market trends, Robotmaster 2024 supports programming multiple robots in a single work cell and meets the demand for automatic trajectory optimization and robotic error correction. In addition, the software update includes improvements to the cell and tooling editor, as well as improvements to the UX (User Experience) and UI (User Interface) to ease the programming experience, maximizing productivity for the user.

“We are excited to announce the release of Robotmaster 2024,” said Natalie Adams, Hypertherm Associates product marketing manager for Robotmaster robotic software. “This latest version of our robotic programming software includes new features and functionality that not only decreases programming time but also removes many of the programming nuisance’s robot programmers encounter.”

Robotmaster 2024 is designed for users who need to program multiple robots to perform a variety of processes within the same cell environment. The ability to program multiple robots enhances the programming workflow and gives the user a single view of the entire system to review the workspace for collisions. In addition, users can now leverage Robotmaster’s powerful programming capabilities and unmatched optimization strategies to shorten cycle times and increase output in multi-robot cell environments.

Robotmaster 2024 also comes equipped with Auto Solve, a new automatic optimization and error correction tool. Auto Solve empowers users of all levels of expertise to program industrial robots confidently in alignment with Hypertherm Associates’ mission to deliver an intuitive and easy-to-use software solution.

“Auto Solve leverages our users’ favorite optimization and correction tools,” said Daniel Marcovici, Hypertherm Associates senior product owner for Robotmaster robotic software. “We’ve designed this new feature so that users can optimize the robot trajectory and correct robotic errors in a single click.”

Robotmaster, a Hypertherm Associates brand, is an offline programming software for robots that helps manufacturers maximize productivity on production runs of all sizes. Robotmaster makes programming parts of any complexity quick and easy as a result of its integrated CAD/CAM functionality. This intuitive and powerful solution is designed with process experts in mind reducing the need for programming and robotic expertise.