Drive High Quality and Predictable Output at the Machine

SigmaNEST 24 suite helps users in three ways: Deeper software integration, a more effective UI, and CAD/CAM enhancements that drive predictably high-quality output at the machine.

Posted: August 19, 2024

SigmaNEST a leading innovator in CAD/CAM, shop floor, and business software for the fabrication industry, offers version 24 of the software suite. The new release gives fabricators the tools to reach higher productivity throughout the shop, while being easy and intuitive to use.

New features include:

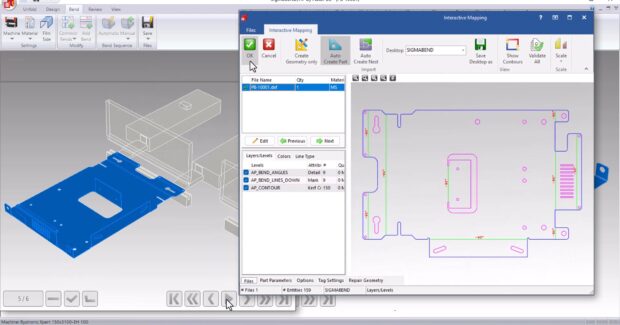

- The new SigmaBEND AP integration improves the automatic transfer of bending data for part creation, time estimation and quoting into the Connected Shop.

- The new SigmaTUBE 24 for SOLIDWORKS integrates completely with the SigmaNEST platform, including powerful new access to the jobs and inventory system.

- The new SimTrans 24 gives customers and IT personnel the tools needed to customize data connections to streamline their operations.

- The SimTrans Studio window gives users access to settings for app integrity, SigmaNEST license configurations, databases and plugins, hardware environment, and shortcuts.

For laser, plasma, oxyfuel and other profile cutting processes, SigmaNEST 24 defines the part profile sequence for any time that part is cut. This one-time setting at the part level reduces programming effort, improves process reliability, and produces predictable cutting results.

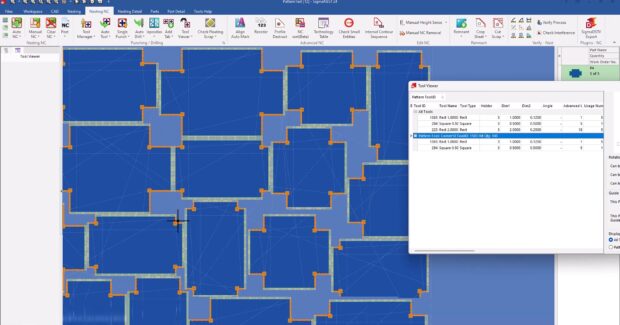

SigmaNEST 24 adds punch tool recognition into the HD SuperNest engine for auto nesting and auto tooling for punch and punch-combi operations. The new Elastic Tooling expansion can detect similar use cases for any part regardless of size and automatically suggests using the specified tooling for that part feature.

For complete details on the benefits of SigmaNEST24, visit the SigmaNEST website.