Build a Resilient Workforce

While utilizing digital platforms and technologies such as virtual reality for workforce training are powerful tools, there is no substitute for hands-on training.

Posted: August 28, 2024

You know you are on to something when you are first to market with a virtual reality (VR) training program and your competitors flock to your booth on a slow day at a trade show to try out the VR, engaging in friendly competition and camaraderie to see who can virtually cut, grind and clean surfaces the best. The team at Weiler Abrasives originally developed Weiler Virtual World as a marketing tool to raise awareness and gather leads at trade shows, trying it out in Europe, initially. The use of VR headsets generated buzz as to the Weiler Abrasives brand, its products and so forth. It has since evolved into a tool that helps end users and operators learn how to work safely and correctly with abrasives in their everyday work environments.

You know you are on to something when you are first to market with a virtual reality (VR) training program and your competitors flock to your booth on a slow day at a trade show to try out the VR, engaging in friendly competition and camaraderie to see who can virtually cut, grind and clean surfaces the best. The team at Weiler Abrasives originally developed Weiler Virtual World as a marketing tool to raise awareness and gather leads at trade shows, trying it out in Europe, initially. The use of VR headsets generated buzz as to the Weiler Abrasives brand, its products and so forth. It has since evolved into a tool that helps end users and operators learn how to work safely and correctly with abrasives in their everyday work environments.

Weiler Abrasives is developing version 2.0 of the Weiler Virtual World training, which will be available to the broader public by the beginning of next year. The new version will be available in additional languages, with an expanded product line, including Tiger products used in the American market, as well as the company’s newest products. The biggest improvement is the ability to access the training from different platforms enabling more users to download the training and use it on their own VR equipment.

At this time, the Weiler Virtual World training consists of two stages, said Špela Kovačič, who is based in Slovenia and is the marketing manager for Europe, the Middle East and Africa — “and what’s in between.” Her team collaborated with partners to develop the virtual reality technology for Weiler Abrasives a couple of years ago. The company is an industry leader and global manufacturer of surface conditioning solutions.

The first stage of the VR gaming is focused on Personal Protective Equipment (PPE), where users dress a dummy with glasses, gloves, safety shoes, etc. “There are also a few funny elements just to have that ‘gaming experience,’ because learning in a fun way — I say people always remember — so we included rubber duckies as a fun element,” Kovačič said. “And from the change room, you enter the shipyard.”

In the shipyard, users have three tasks: cut, grind and use a power brush. They first have to choose the correct angle grinder with the correct protection for the grinder. They also have to choose the right disc for the material. At the work station, users are graded and earn points based on the correct application of cutting, grinding and brushing. For example, how many cuts can they make? Is the angle correct? Is the user moving the tool correctly?

“But, as with every game, you are time limited and at the end the person that works the best or didn’t make any mistakes, gets the most points,” Kovačič said.

Fun engagement is just one aspect of VR training. It also offers the benefits of allowing users to make mistakes in a safe environment such as virtual reality — making mistakes in a shop can cause injury. “And for a beginner, for somebody who has never done it before, if somebody is scared of doing it, this is a great opportunity,” Kovačič said.

What’s more, through VR, staff are receiving the necessary training that enables them to start contributing immediately once in the shop. As an example, workers involved in assembly line production know where things are located at the job site, so they are not losing time searching for something to perform their jobs. They already know how to select the right tools and discs to work safely. “This is what these modern tools can give us, and I see it as a trend, especially in Europe, where they are leveraging it,” Kovačič said.

New Technologies are Transformational But Hands-on Training is Fundamental

Today, workforce training efforts using the latest technologies such as VR, digitalization, automation and AI no doubt support increases in productivity and quality as trainees are ready to hit the ground running. These initiatives also foster a culture of continuous improvement and innovation within the existing workforce. And while these training programs can address specific skill gaps and reduce downtime in a tight labor market, they should be viewed as tools in a comprehensive training effort, which can include hands-on training and tailored apprenticeships.

While VR and gamification, for example, support increased engagement, and AI-driven personalized learning paths progress with each employee, there is no substitute for hands-on training, noted Karolyn Ellingson, the head of industrial workforce development at Festo Didactic.

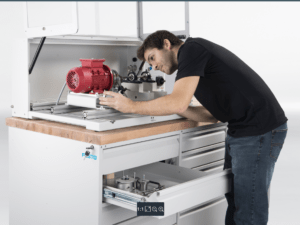

Festo Didactic is the training arm for Festo, a global leader in automation technology. Ellingson said that Festo Didactic takes the model of 70% hands-on training and 30% theory, in general, regarding skills development and retention. Workforce training initiatives span the range of equipment for efficient learning, from simulation software, eLearning (such as the Festo LX platform with online courses), and modular learning systems, to fully equipped training centers for a wide variety of technology fields. The training includes instruction such as factory automation and Industry 4.0, industrial maintenance, fluid power, robotics, digital eLearning, energy efficiency and renewable energies, electrical engineering and electronics, and lean or operational excellence.

Corporate training programs, either those within a company or training shared with other companies, schools or other organizations, are vital to building a resilient workforce. Within Weiler Abrasives, for example, the company is now rolling out a Brush Maker career pathway, focusing initially on operations, with plans to expand the training program to technicians, and the tool room. Under the initiative, employees known as “Champion” trainers complete 30 hours of course work so they can train new hires and re-train co-workers in order to improve their efficiency levels. The champions are still running machines in the shop, but they are also culture champions, exhibiting the Weiler Way, and leading by example. “They are a person that is looked up to, to really promote change within our organization,” noted Jane Burkholder, the senior HR manager for Weiler Abrasives, Cresco, Pa. “There’s that duality of yes, they are trainers, but they are also mentors and culture champions, so that is a benefit.”

When it comes to new hires, under the Brush Maker program, employees are able to get up to speed quicker and are more confident in their skills. The confident employees provide better outcomes, both in their performances and for the business, Burkholder added. “The quicker you feel secure in your job and your skill sets, the more likely that you are going to actually stay and be happy and retain there.”

The Brush Maker career program supports Weiler Abrasives as the company moves from a scattershot approach to training (there are 76 different manufacturing operations) to one that is organized into career blocks, which represent a career step forward. Once an employee learns a new machine they are promoted to a junior Brush Maker and so on. “We are really building in that structure, giving co-workers the career path to take charge of where they are going,” Burkholder said. “They have options.” Additionally, employees are not just training on machines but also learning lean components and safety components.

Companies such as Airgas and Ingalls Shipbuilding also believe in providing career pathways and are attracting the next generation of talent into metalworking careers by donating their products and equipment to deserving manufacturing training programs at schools, as well as offering hands-on instruction or access to experts to help train and prepare the future metalworking workforce.

In the case of Airgas (Radnor, Pa.), the company is working to close the gap regarding unfilled welder positions. For the 2024 academic year, 65 schools from 29 states are participating in the Airgas High School Welding Education Initiative. Donations from Airgas include products such as welding gases, materials or equipment, and PPE such as welding helmets and gloves. What’s more, Airgas’ branch members and welding process specialists collaborate with teachers at each school regarding curriculum. (See sidebar “Welding Education Initiative Empowers Students to Fill Their Potential” to learn more.)

In the Mobile, Ala., region, Ingalls Shipbuilding, a division of Huntington Ingalls Industries, has formed a collaboration with the Maritime & Industrial Welding Academy at Alma Bryant High School located in Irvington, which is 20 miles from Mobile. The company consistently provides the academy with everything needed to maintain a successful welding program and made a substantial investment in 2018 of welding equipment and more when the partnership began. “Our shared goal is to provide students the opportunity to build a solid future for themselves and their families, while also nurturing a strong talent pool for our shipyard’s next-generation workforce,” stated former Ingalls Shipbuilding President Brian Cuccias at the time of the announcement regarding partnerships with Bryant High School and other schools. “Our employees are partnering with the schools and instructors to teach these students how to weld, use machinery and other shipyard craft. They will also learn how to work safely and how to transition into industry by learning basic life skills.”

“Our welding students will be learning real-life skills to prepare them for jobs in the maritime field, which is exactly what we mean when we say that Mobile County Public Schools are preparing students to be college and career ready,” added Chresal Threadgill, superintendent of Mobile County Public Schools, when the partnership was announced.

In Irvington, Ingalls Shipbuilding setup the Bryant High School academy with new welding booths that were large enough to support the comfortable instruction for both men and women occupants; new welding machines; welding rods; safety gloves, safety glasses, jump suits and boots; welding and grinding shields; and all the metal the school requires, said George Crenshaw, who is a welding instructor at Bryant High School’s Maritime & Industrial Welding Academy. Prior to that he had a 37-year career in the welding sector. “This is not a one-time deal,” Crenshaw added. “Throughout the year, Ingalls Shipbuilding sends materials as I need them. They also send welders once a month to work with and get to know the students, and make sure I am teaching what they want me to teach.”

Additionally, twice a year, Ingalls Shipbuilding invites welding students to visit the shipyard where they view the different crafts: welding, electric, scaffold building, crane operations, rigging and carpentry. The company also provides employees who share tips on the soft skills of a manufacturing career, including finance and investing.

The Bryant High School academy instructs 65-to-70 students throughout the day; with eight-to-14 seniors involved in the apprenticeship programming with Ingalls Shipbuilding. The seniors, who go through an interview process, train at Ingalls Shipbuilding for three hours a day, four days per week, receiving instruction on scaffold building, electrical, welding, blueprint reading and more.

“If a student misses five unexcused days they are dismissed from the program,” Crenshaw said. “Most every one of the students that completes the program are hired on by Ingalls Shipbuilding.” Upon completion of the apprenticeship, the students can go to work outside of Ingalls Shipbuilding; there are many local shipyards around the Mobile region. “Over the last eight years … we have 25-to-30 students that went through the program that are still with Ingalls,” Crenshaw said. “And most of them have moved into a management position such as a lead or second supervisor, or have moved into the pipe welding department, which is the department most welders want to get into.”

Apprenticeship programming is vital to Ingalls Shipbuilding’s workforce attraction and retention efforts. In March, the company hosted an apprentice graduation program, celebrating 99 graduates at the company’s shipyard in Pascagoula, Miss. Enrollment for the apprenticeship program is competitive, and students work full-time while learning a craft through classes and on-the-job training. There are 700 students enrolled in the apprenticeship program, the highest enrollment since prior to the pandemic.

Certified, Well Trained and Adaptable

Certification programs are also an important component regarding the incoming generations of metalworking employees. For its part, Festo Didactic partners with the National Coalition of Certification Centers, the PMMI Mechatronics Certification, and the National Institute for Metalworking Skills, to validate workers’ skills. Many of the training classes offered by Festo Didactic feature embedded certifications, Ellingson noted. Once a trainee completes classes in pneumatics, for example, they can test for a certification.

The company also offers apprenticeship programs, such as mechatronics, which combine classroom learning and hands-on experience. The company partners with the Mechatronics Apprenticeship Program in southwestern Ohio, where small- to medium-size companies participate in a consortium to train apprentices in advanced manufacturing skills.

Ellingson pointed out that apprenticeships are flexible, where regional apprentices, sponsored by their employers, attend Festo one day a week. This approach usually spans about one year and can earn participants up to 20 credit hours toward an associate’s degree through Sinclair Community College in Dayton, Ohio.

“For individual companies sending their employees, we offer even more flexibility,” Ellingson added.

For example, at this time, Festo Didactic is working with a local greenfield site in Ohio, training up to 60 technicians over a week at a time following the apprenticeship curriculum. Each individual then practices their skills either on site or at a sister facility, which allows “us to reduce the program length to just eight weeks,” Ellingson added.

The time it takes to train can cut into production schedules; however, there are ways to train new hires and existing staff without disrupting production. Ellingson said that the length of training programs can be tailored to the specific needs of customers. “What sets Festo Didactic apart is our ability to adapt to industry demands,” she noted. “If the customer has multiple shifts to cover, we can accommodate that. If employees can only be off the floor for four hours at a time, we can schedule Group A in the morning and Group B in the afternoon. While this may extend the number of days we’re on site, it ensures that employees receive the necessary training without disrupting production.”

Weiler Abrasives’ Kovačič pointed out regarding VR training: “If you are leveraging the production site for trainings, you are not getting the output, you are not producing. You are training, which means money lost.” Investing in solutions that are off site or in a virtual world allows you to keep the business running. What’s more, a trained workforce can go in and start working immediately — and safely.

Ellingson summed up a successful approach to the workforce training equation. Metalworking manufacturers can generate significant value through training efforts by adopting a proactive and holistic approach to workforce development, she pointed out. “By investing in comprehensive training programs, manufacturers can upskill and reskill their existing employees, ensuring they are proficient with the latest technologies such as digitalization, automation and AI. This not only enhances productivity and quality but also fosters a culture of continuous improvement and innovation.”

Finally, tailored training programs can help address specific skill gaps, optimize workflows, and reduce downtime, ultimately leading to increased efficiency and competitiveness — and build a robust and adaptable workforce.

AWS Foundation Boosts Welder Training Opportunities with Grant Funding

As demand for skilled welders in manufacturing and construction continues to soar, the American Welding Society (AWS) Foundation (Miami, Fla.) continues to provide financial assistance to train the next generation of skilled welding professionals.

In July, the AWS Foundation announced 14 schools nationwide were selected to receive grants that will enable them to elevate their training facilities and better equip students. Each year, the AWS Foundation provides grant funding of up to $25,000 per location to secondary, postsecondary, and welder training facilities to enhance and expand welding education programs. Grant funding may be used on facility improvements, investing in welding or metalworking equipment, and upgrading computer-based training systems.

“Graduates of welding schools are in high demand nationwide, yet many institutions struggle to train enough individuals to meet the local industry’s needs,” said Monica Pfarr, executive director of the AWS Foundation. “We are pleased to support these schools in expanding their welding programs and applaud their commitment and dedication to training the next generation of welding technicians and professionals.”

The AWS Foundation is dedicated to reversing the trend in the decline of the number of skilled welding technicians and professionals by supporting programs that promote the growth and development of the welding industry through research, education, and workforce development initiatives. In 2023, the AWS Foundation awarded more than $3 million in grants and scholarships to advance welding education.

Welding Education Initiative Empowers Students to Fill Their Potential

The number of projected workers required to staff the welding sector is staggering: an average of 82,500 welding positions will need to filled annually between 2024 and 2028, according to the American Welding Society. Airgas (Radnor, Pa.), an Air Liquide company, is one company doing its part to fill those positions.

Through its Airgas High School Welding Education Initiative, the company works with local representatives and educators to attract students to welding career opportunities. Airgas is a leading U.S. supplier of industrial, medical and specialty gases, as well as hardgoods and related products, and one of the largest U.S. suppliers of safety products.

For the 2024 academic year, 65 schools from 29 states are participating in the initiative. The initiative began in 2012 with a pilot program in Philadelphia, Pa., and was rolled out nationally in 2018. In that time, Airgas has assisted 117 schools, more than 8,100 welding students and nearly 560 instructors across the country, writes Kim Menard, director of corporate communications for Airgas. Nearly 1,000 of the students have obtained jobs directly upon graduating from a school program supported by donations from Airgas.

High schools are nominated by Airgas associates located within their local communities. Faculty and students determine the equipment and resources that are most needed for their welding programs and can customize their donation selection from Airgas. Donations include products such as welding gases, materials or equipment and PPE. Airgas branch members and welding process specialists collaborate with teachers at each school. Training is customized to each school and varies based on their needs and academic curriculum, said Matt Williams, vice president of advance fabrication markets-business development, for Airgas.

“Together, we can collectively prepare job-ready welding program graduates and support the communities in which we operate,” Williams said. Added Menard, “This program’s growth is possible because of our many passionate associates who are stepping up to share their expertise in the communities where they live and work, as well as our customers, colleagues and collaborators who continue to advocate for the importance of welding education.”