Norton Invites FABTECH attendees to “Work Smart with Norton”

Saint-Gobain Abrasives, one of the world’s largest abrasives manufacturers, has announced that at FABTECH 2024, Booth #W3301, located in the Orange County Convention Center, 9800 International Drive Orlando, FL from October 15-17, it will feature how to “Work Smart with…

Posted: July 12, 2024

Saint-Gobain Abrasives, one of the world’s largest abrasives manufacturers, has announced that at FABTECH 2024, Booth #W3301, located in the Orange County Convention Center, 9800 International Drive Orlando, FL from October 15-17, it will feature how to “Work Smart with Norton” by exhibiting a range of abrasives that optimize the user experience. Norton abrasives to be highlighted at FABTECH will include the latest in grinding, cut-off, blending and finishing solutions to address today’s challenging application requirements. Norton continually researches, designs and manufactures abrasives, as well as offering grinding application guidance, by prioritizing the user experience.

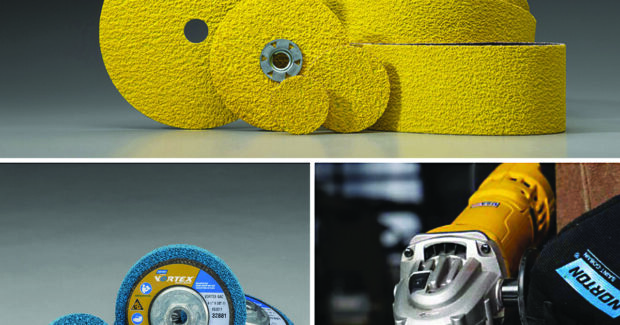

Set for a second unveiling at a major industry trade show in North America are New Norton RazorStar™ belts, quick-change and fiber discs featuring innovative engineered-shaped ceramic grain, a revolutionary technology with unbeatable performance and metal removal rates in the toughest grinding applications when performing off-hand and/or automated grinding.

Norton RazorStar products include uniquely-shaped razor-sharp grains in an upright position along with a special supersized grinding aid, significantly reducing heat generation for cooler cuts and longer life on a range of materials such as carbon steel, aluminum, stainless steel, nickel alloys and other hard-to-grind metals. In addition to impact grinding and off-hand applications, RazorStar belts are ideal for robotic applications in markets such as aerospace, automotive, oil and gas and general machining.

FABTECH attendees can also learn about the Norton Abrasive Process Solutions (APS) Program, which helps customers determine the optimal grinding or finishing solution for the application at hand, ranging from simple to complex, off-hand or automated, and for metal fabrication, production grinding and virtually any abrasives operation.

Additional abrasives to be highlighted at Norton’s FABTECH booth will include:

- Norton Vortex® Rapid Prep Non-Woven Flap Discs last longer and produce significantly increased cutting rates and smear-free finishes simultaneously. Norton patented Vortex agglomerated aluminum oxide grain technology enables the cutting power of a coarser grit while producing a finer finish in one abrasives disc solution.

- Norton Vortex® Rapid Blend Coarse Grit Wheels and Discs offer a finishing process solution that reduces and blends welds in a single operation, providing a 30% – 50% improvement in productivity, while leaving smear-free finishes.

- Norton QUANTUM3™ (NQ3) Line of Grinding and Cutting Wheels cut fast and sharp, achieving increased metal removal in less time, with reduced operator fatigue, to significantly increase grinding output and lower costs. The wheels feature a proprietary grain along with a tougher bond system containing a unique combination of fillers and bonding agents.

- “Norton for Aluminum” Thin Wheels offer right angle cutting and grinding of aluminum and other soft non-ferrous metals. High quality, extra-friable and self-sharpening aluminum oxide grain and specialized bond technology results in the best cutting and grinding wheel performance in its class.

ABOUT SAINT-GOBAIN ABRASIVES

Saint-Gobain Abrasives offers powerful, precise, user-friendly solutions which enable customers to cut, shape and finish all materials in the most complex and challenging applications. By working closely with end-users and grinding expert partners, Saint-Gobain Abrasives designs and provides customized solutions to secure the best option for performance, cost and safety. Leveraging its global manufacturing presence, Saint-Gobain Abrasives serves its customers locally through its structured sales operations in over 27 countries, employing over 10,000 people.