Produce Versatile, High-quality Gears at Lower Costs

Innovations in machining technologies and processes optimize gear manufacturing.

Posted: June 11, 2024

Improvements in technology ensure the consistent and cost-efficient delivery of high-quality gears for demanding applications.

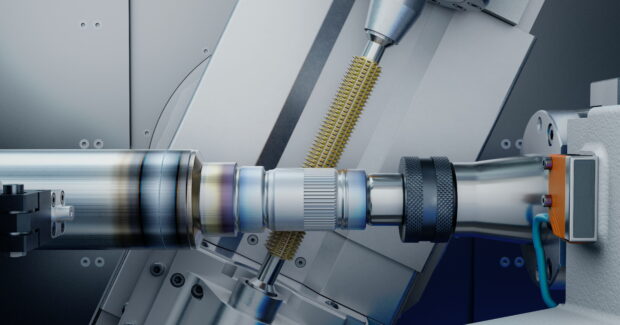

Industry-first In-process Measurement of Skiving Cutters

The popularity of skiving is driven by electric cars. According to the Global Electric Vehicle (EV) Outlook 2023 report, there were more than 26 million electric cars on the world’s roads in 2022, 60% more than in 2021 and five times as much as in 2018. Responding to this demand, ANCA CNC Machines (Wixom, MI) brings a complete solution for manufacturing and sharpening skiving cutters as part of a comprehensive gear cutting tool package. The GCX Linear sets the new standard for producing the highest quality skiving tools in both carbide and HSS. Its in-process measurement with the analog probe provides an accurate closed-loop manufacturing process, an industry-first innovation.

Notable features of the GCX Linear include MTC (Motor Temperature Control), AEMS (Acoustic Emission Monitoring System), high accuracy headstock and comprehensive software package. MTC dramatically reduces warmup time and offers thermal stability. ANCA’s AEMS can be taught to pick up the right sound of perfect dressing in noisy production environments. Built upon a supervised machine learning algorithm, AEMS ensures the wheel profile is dressed within micron accuracy with the least possible time while minimizing the reduction in size.

Large disk type skiving cutters and shaper cutters require higher headstock accuracy, as the impact of A-axis positional error will linearly increase with diameter. The GCX Linear software package includes multiple software components for manufacturing and resharpening pinion type gear cutters. It includes design, simulation, grinding sequence programming, wheel editing and wheel dressing.

Flexible Machine Hobs Gears and Mills Worms

Highly versatile and productive, EMAG Koepfer’s (Farmington Hills, MI) horizontal HLC 150 H can machine a huge range of workpieces, from gear shafts to steering pinions and worm gears to planetary gears. This machine offers a high level of productivity for components up to 20” long and weighing up to 22 pounds.

When machining rotor shafts, for example, the HLC 150 H enables short cycle times and achieves a gear cutting quality of DIN 7. Its horizontal design ensures stable and process-reliable hobbing and prevents the formation of chip clusters, resulting in higher efficiency and quality. The machine is designed for connection with automation, too, making it ideal for modern production environments. Particularly noteworthy is the integrated, high-speed gantry loader, which enables workpieces to be handled quickly and efficiently. This adaptability to different levels of automation makes the HLC 150 H a key tool for efficient and scalable mass production, especially for e-mobility, where high quantities and consistent quality are required.

Coniflex Pro for Differential Gear Design and Production

Gleason Corp.’s (Rochester, NY) Coniflex® Pro Design and Manufacturing System is ideally suited for producing stronger, quieter, and more reliable e-drive differential gears in high volumes, for automotive, truck, bus and off-highway transmissions.

Differential gears in e-drive applications must respond to significantly increased requirements: higher bending and surface stress capabilities, higher load density, NVH considerations and noise reduction, as well as dynamic loads. With Coniflex Pro software, surface stress is reduced up to 40%, root bending up to 30% compared to forged gears, resulting in higher load density and significantly extended gear life.

For e-drive disconnect transmissions, NVH behavior becomes even more critical. Differential load cases are more dynamic than the former rather static loads. Coniflex Pro provides for lower transmission errors and excellent NVH results compared to forged gears. It relies on the proven Coniflex Plus carbide cutter system and Phoenix® bevel cutting and grinding machines for highest levels of quality and productivity. Coniflex Pro is part of Gleason’s GEMS® Design Software Suite. The Coniflex Pro app provides extended design capabilities including higher order modifications for a closed loop production environment.

Coniflex Pro is applicable to all types of straight bevel gears. The related processes, Coniface™ and Coniflex, are applicable to face gears and clutches.

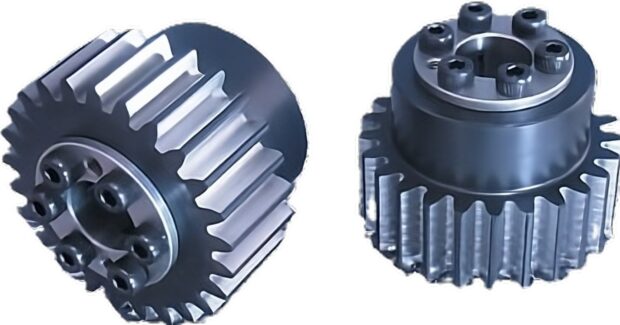

Extensive Line of Metric Spur Gears with Locking Hubs

KHK USA Inc. (Mineola, NY), a factory owned distributor of the market leading KHK® brand of metric gears, announces its extensive line of metric spur gears which are offered with several types of locking hubs. More than 8,000 configurations of off-the-shelf KHK Spur Gears are available in many materials, configurations, modules, and numbers of teeth.

KHK’s SS Series Spur Gears are minimum plain bore spur gears made from 1045 carbon steel. The “F” series version of these gears includes a tapered bore locking hub which is preassembled for ease of use. These gears are available in pitch sizes Module 0.5 through Module 10 with 12-to-200 teeth and are designed for use in general industrial automation applications.

KHK’s SSA Series Spur Gears are hub less versions of the SS series and are available in Modules 1 through 6 with 15-to-200 teeth. These gears are also available with the “F” series tapered locking hub.

KHK’s SSG Series Spur Gears are similar to the SS series with the addition of the tooth surfaces being induction hardened to HRC 50-55 for added durability. After heat treating these gears have their teeth ground finished for higher precision. The “F” series taper locking hub option is available for these gears in addition to the “E” series keyless locking hub. The “E” series hub is preassembled with the SSG gear and will lock onto the shaft with one twist of the locking screw.

With these locking hub options, KHK spur gears are ready to use and are easy to install. There is no reworking of the bore required by the end user, and the hubs allow for easy disassembly when needed.

KHK also offers spur gears made from 303 stainless steel, MC901 nylon, acetal, high-strength chromoly steel, and brass, for applications where carbon steel is not suited.

High Productivity with the Lowest Possible Per-piece Costs

“Flexibility and productivity” – true to this motto, Klingelnberg GmbH (Hueckeswagen, Germany) is driven to provide simple, unconventional solutions to high-tech challenges. Case in point: the Oerlikon bevel gear cutting machine C 30 is based on established development concepts that are continually being advanced. Success factors include high productivity with the lowest possible per-piece costs and maximum process safety; and a unique closed loop concept for the entire bevel gearing process chain.

All bevel gear machines in the Oerlikon series are equipped with a thermostable, vibration-damping machine bed. The cutting machine utilizes an optimized axis arrangement, resulting in reduced approach paths that ensure a significantly reduced load on the drive components and at the same time a stiffer design of the complete system. Moreover, an integrated deburring tool provides maximum productivity for deburring and the utmost process safety through the use of the PULSAR method. Use of the optional power skiving method makes it possible to achieve even greater machine flexibility and productivity. A key highlight of this machine series is its innovative operating concept and ultra-modern control technology. The modern touchscreen display and the newly developed operating concept make the C 30 more intuitive to operate compared with standards commonly found on the market.