New Turning Tool Holders for Positive Indexable Inserts

New Walter turning tool holders deliver efficiency by precisely directing coolant to exactly where it is needed.

Posted: June 26, 2024

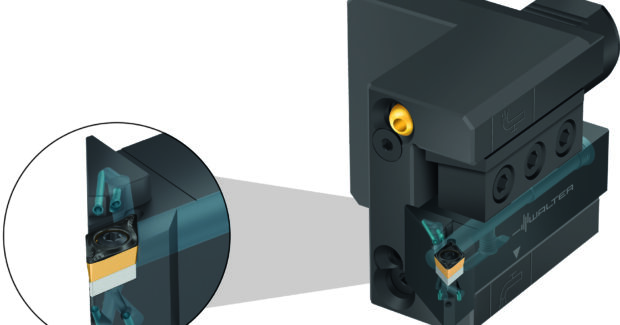

Walter has introduced the Walter Turn tool holder with precision cooling and screw clamping (S…-P). Coolant is targeted on the rake face and flank face to maximize the cooling effect. In addition, rake face cooling helps break and control chips, and double flank face cooling directly at the cutting edge extends tool life.

Users can apply a coolant pressure from 145 to 2,175 psi (10 to 150 bar). Improved chip breaking occurs when the coolant pressure is greater than 580 psi (40 bar). Optimum coolant application increases tool life by 30% to 150%.

The toolholder features a flexible coolant connection: Direct coolant transfer to a VDI tool adaptor (A21XX-P) or via a coolant hose set with G1/8″ thread (K601). The turning tool holder provides a universal adjustment range.

The toolholder accepts CCMT3…, DCMT3… and VBMT3… (CCMT09…, DCMT11… and VBMT16…) indexable inserts. The shank dimensions are 0.75″ × 0.75″, 1″ × 1″, 20 mm × 20 mm and 25 mm × 25 mm.

Suitable applications include longitudinal turning, facing and profile turning of components with a small diameter. The Walter Turn turning tool holders are an excellent choice for machining stainless steel,

high-temperature alloys and steel (ISO M, S and P workpiece groups).

Potential benefits include the ability to cut at higher speeds and longer tool life thanks to the flank face cooling. The tool holder enables the production of short, manageable chips thanks to the rake face cooling. Because coolant nozzles no longer need to be adjusted manually, end users will see improved machine availability and ease of operation.

Walter, a global leader in the metalworking industry for over 100 years, offers a wide range of precision tools for milling, turning, drilling and threading applications. The company helps customers in the aviation and aerospace industries, automotive, energy, and general metalworking industry improve process reliability and increase productivity. As an innovative partner capable of creating digital process solutions for optimal efficiency, Walter is pioneering Industry 4.0 throughout the machining industry. With Regional Headquarters in Greer, SC, Walter markets its competence brands Walter, Walter Titex, Walter Prototyp and Walter Multiply through a network of channel partners and field engineers across the USA, Canada, Mexico and Brazil. www.walter-tools.com/us.